4

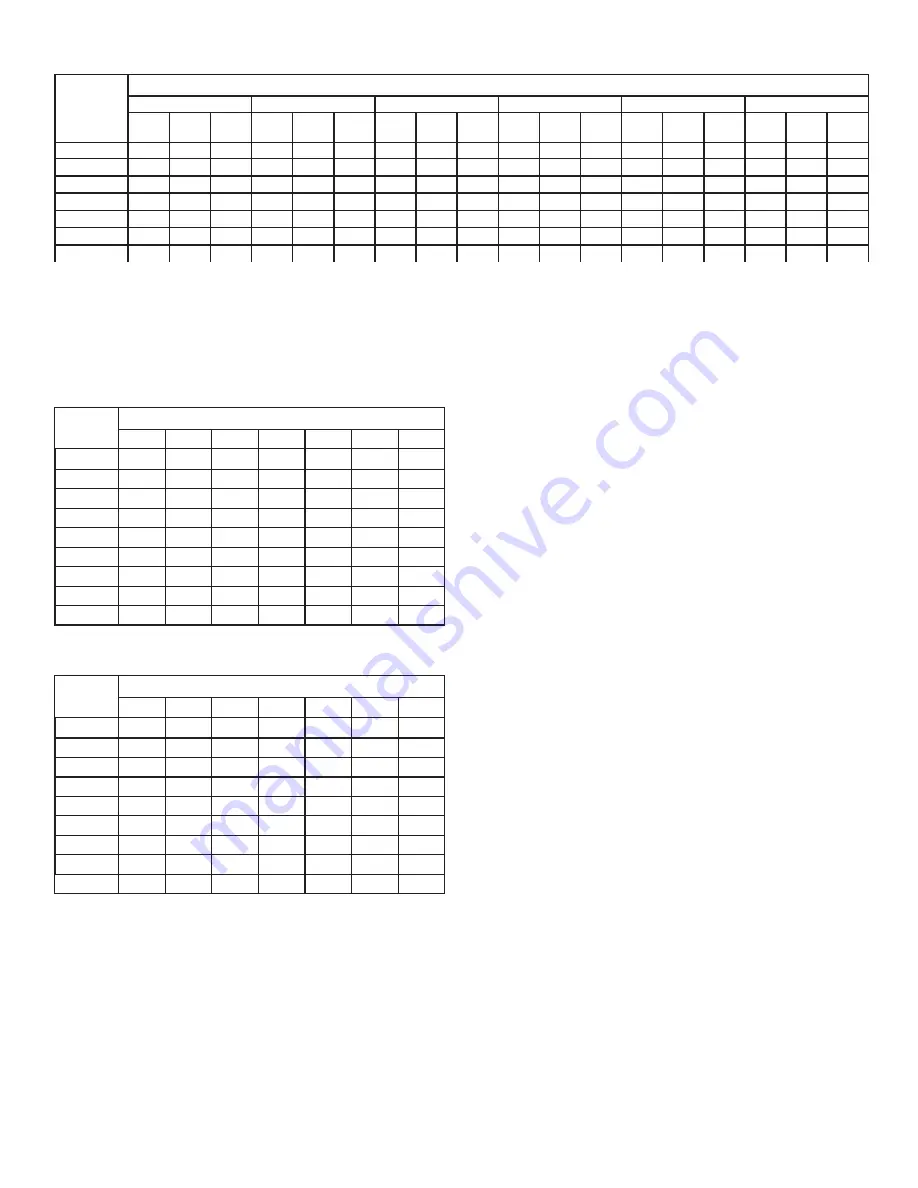

Table 1 - Oil Volumes

Reducer

Size

Volume of Oil Required to Fill Reducer to Oil Level Plug

Position A

Position B

Position C

Position D

Position E

Position F

Fluid

Oz.

Qts. Liters Fluid

Oz.

Qts. Liters Fluid

Oz.

Qts. Liters

Fluid

Oz.

Qts. Liters Fluid

Oz.

Qts. Liters Fluid

Oz.

Qts. Liters

(H)SCXT105

20

5/8

.59

24

3/4

.71

20

5/8

.59

24

3/4

.71

36

1

1.06

44

1

.30

(H)SCXT205

24

3/4

.71

28

7/8

.83

28

7/8

.83

28

7/8

.83

56

1-3/4

1.66

72

2-1/4

2.13

(H)SCXT305A

28

7/8

.83

48

1-1/2

1.42

44

1

1.30

44

1

1.30

80

2-1/2

2.37

100

3

2.96

(H)SCXT405A

48

1-1/2

1.42

72

2-1/4

2.13

68

2

2.01

60

1

1.78

128

4

3.79

156

4

4.61

(H)SCXT505A

108

3

3.19

136

4-1/4

4.02

124

3

3.67

120

3-3/4

3.56

248

7-3/4

7.33

288

9

8.52

SCXT605

144

4-1/2

4.30

184

5-3/4

5.40

144

4-1/2

4.30

160

5

4.70

384

12

11.40

352

11

10.4

SCXT705

240

7-1/2

7.10

288

9

8.50

240

7-1/2

7.10

296

9-1/4

8.80

608

19

18.0

552

17-1/4 16.30

Below 15 RPM output speed, oil level must be adjusted to reach the highest oil level plug (P).

Refer to Figure 3 for mounting positions.

Note:

If reducer position is to vary from those shown in Figure 3, either more or less oil may be required. Consult Dodge product support.

U.S. Measure: 1 qt. = 32 fl. oz. = .94646 liters.

All liquid measure amounts are approximate.

CAUTION: Do not use oils containing slippery additives

such as graphite or molybdenum disulphide in the reducer

when backstop is used. These additives will destroy sprag

action. Failure to observe these precautions could result in

damage to, or destruction of, the equipment.

GUIDELINES FOR TORQUE-ARM REDUCER

LONG-TERM STORAGE

During periods of long storage, or when waiting for delivery or

installation of other equipment, special care should be taken

to protect a gear reducer to have it ready to be in the best

condition when placed into service.

By taking special precautions, problems such as seal leakage

and reducer failure due to lack of lubrication, improper

lubrication quantity, or contamination can be avoided. The

following precautions will protect gear reducers during periods

of extended storage:

Preparation:

1. Drain the oil from the unit. Add a vapor phase corrosion

inhibiting oil (VCI-105 oil by Daubert Chemical Co.) in

accordance with Table 4.

2. Seal the unit air tight. Replace the vent plug with a standard

pipe plug and wire the vent to the unit.

3. Cover the shaft extension with a waxy rust preventative

compound that will keep oxygen away from the bare metal.

(Non-Rust X-110 by Daubert Chemical Co.

4. The instruction manuals and lubrication tags are paper

and must be kept dry. Either remove these documents

and store them inside or cover the unit with a durable

waterproof cover which can keep moisture away.

5. Protect the reducer from dust, moisture, and other

contaminants by storing the unit in a dry area.

6. In damp environments, the reducer should be packed

inside a moisture-proof container or an envelope of

polyethelene containing a desiccant material. If the reducer

is to be stored outdoors, cover the entire exterior with a

rust preventative.

Table 2 – Lubrication Recommendations – ISO Grades for Ambient

Temperatures of 15ºF to 60ºF

Output

RPM

Reducer Size

1

2

3

4

5

6

7

301-400

220

220

150

150

150

150

150

201-300

220

220

150

150

150

150

150

151-200

220

220

150

150

150

150

150

126-150

220

220

220

150

150

150

150

101-125

220

220

220

220

150

150

150

81-100

220

220

220

220

220

150

150

41-80

220

220

220

220

220

150

150

11-40

220

220

220

220

220

220

220

1-10

220

220

220

220

220

220

220

Table 3 – Lubrication Recommendations – ISO Grades for Ambient

Temperatures of 50ºF to 125ºF

Output

RPM

Reducer Size

1

2

3

4

5

6

7

301-400

320

320

220

220

220

220

220

201-300

320

320

220

220

220

220

220

151-200

320

320

220

220

220

220

220

126-150

320

320

320

220

220

220

220

101-125

320

320

320

320

220

220

220

81-100

320

320

320

320

320

220

220

41-80

320

320

320

320

320

220

220

11-40

320

320

320

320

320

320

320

1-10

320

320

320

320

320

320

320

Notes:

Below -23ºF call application engineering.

20ºF to -22ºF use Mobil SHC 627.

Above 125ºF use Mobil SHC 634.

NOTE: Pour point of lubricant selected should be at least 10°F lower than

expected minimum ambient starting temperature. See last page of manual

for lubricant viscosity classification equivalents. Special lubricants

may be required for food and drug industry applications where contact

with the product being manufactured may occur. Consult a lubrication

manufacturer’s representative for his recommendation.