22

C O N V A C V A C U U M C O N T A C T O R

I N S T A L L A T I O N A N D O P E R A T I O N I N S T R U C T I O N

—

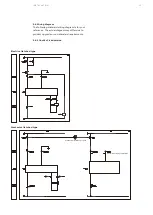

Fig 5d

5.8.2 Racking in and out operation

(

for

withdrawable version

)

While carrying out the racking-in/out operation of

a manual truck, first insert the manual racking-in

handle to the right position

(

Fig 5d

),

clockwise

rotation of the handle will rack-in the contactor to

the working position, anti-clockwise rotation of the

handle will rack-out the contactor to the testing

position.

Operate slowly while racking-in/out the contactor

in order to avoid any deformation of the mechanical

interlocks. The torque needed to carry out truck

handling is < 25 Nm, do not exceed this limit while

operating. If there’s any difficult during the

operation, don’t apply hard push, please check if

the operation sequence is correct.

The earthing devices installed on both sides of the

truck cooperates with the guide rail on the

switchgear, guarantees the reliable earthing

between the ConVac frame and the main earthing

system.

Attention

!

The contactor must only be racked into the

unit in open position.

While racking-in/out manually, the handle

need to turn approximately 20 rounds .

Truck can only be removed

from the switchgear when it

is in test position and the

spindle angle is as this

picture

5.8.3 Withdrawable ConVac with motorized truck

Carry out the racking-in/out test of the motorized

truck in the same way as for a manual truck,

following the instructions below:

•

De-energize the motor power supply circuit, check

whether the contactor is in working or testing

position, whether the positioning interlock on

the truck beam is stuck into the corresponding

slot on both sides of the switchgear, if the 2

handles could pull left and right flexibly

•

First operate several manual racing-in/out

operations with the handle, check if there’s any

jamming during the operation, if the interlock is

in right position

•

Check whether the positive and negative polarity

of motor power is correct

a) Rack the contactor to the middle position

with the handle

b) Take out the handle

c) Supply the truck motor circuit with power

d) Activate the command for the electrical

racking-in/out to check if the moving direction

is correct.

Motorized operation

•

Supply the motor control system (pay attention

to the +/- polarity)

•

Check the contactor position sign

•

While pulling the contactor out of the

switchgear from testing position, make sure

that the spindle angle is as the picture below,

and check the two handles on the truck could be

moved left and right flexibly(if the spindle is not

in place, please adjust it manually)

Please use the MDC2 or MDC4 provided by

ABB as a motor control unit, otherwise the

motor might be damaged.

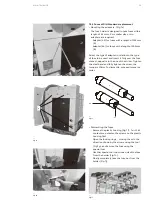

5.8.4 Emergency opening (Only for mechanical

latching)

Emergency opening is only allowed by

specially trained personnel with detailed

knowledge of the equipment.

For fixed and withdrawable version of mechanical

latching ConVac contactor, emergency opening

could be realized in manual mode.

For fixed contactor, please apply < 80 N force and

<20 mm stroke to pull the mechanical release

lever (Fig. 5e) to open the contactor under

emergency situations.

For withdrawable version, please use a special

tool to apply <100 N force and <35 mm stroke to

trigger the emergency opening button on the

front cover (Fig 5f), then open the contactor.

To perform the operation above, please reserve

operating hole on the switchgear door.

Содержание ConVac

Страница 2: ......

Страница 35: ...安装 21 ...