Program features

75

Motor thermal protection

The motor can be protected against overheating by activating the Motor thermal

protection function and by selecting one of the Motor thermal protection modes

available.

The Motor thermal protection modes are based either on a motor temperature

thermal model or on an overtemperature indication from a motor thermistor.

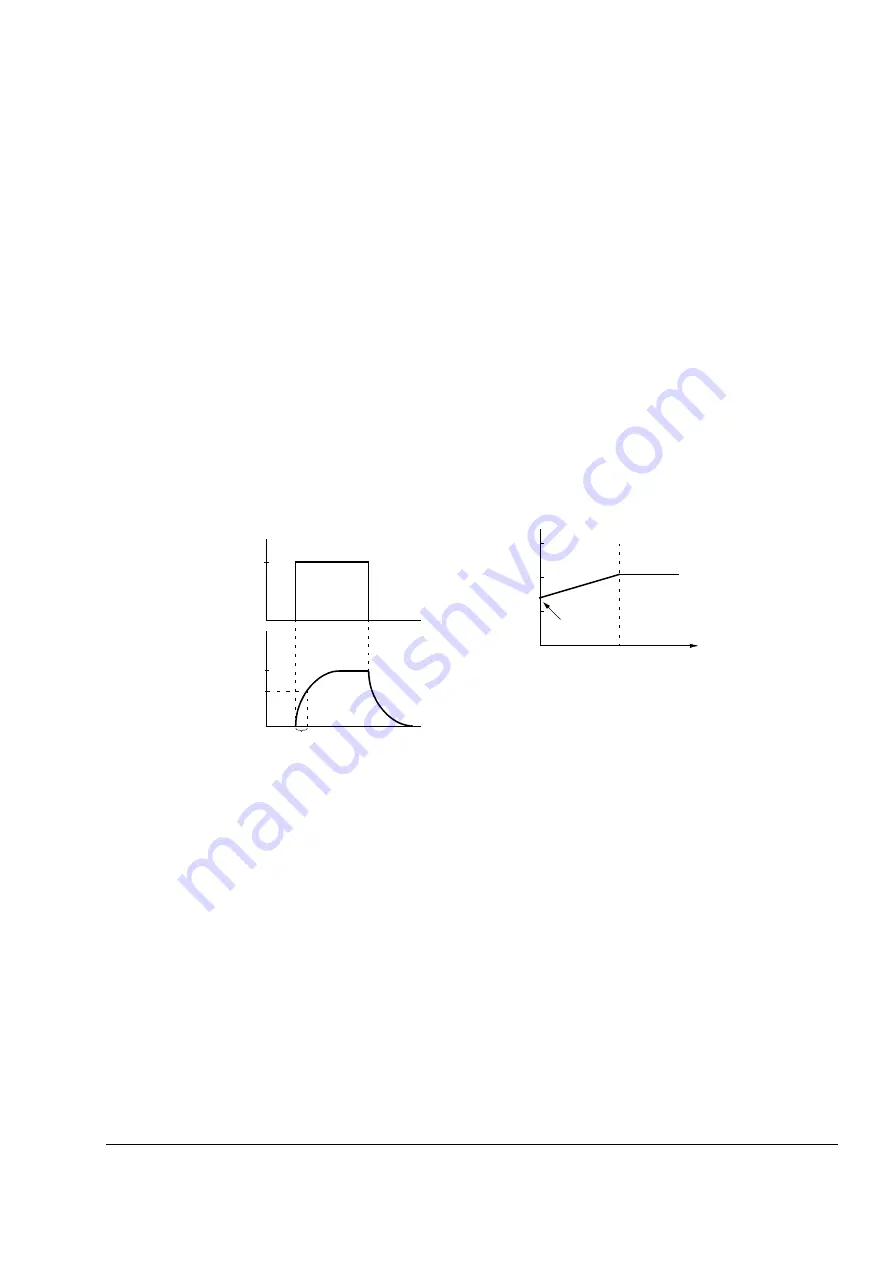

Motor temperature thermal model

The drive calculates the temperature of the motor on the basis of the following

assumptions:

1) The motor is at the estimated temperature (value of

MOTOR TEMP EST

saved at power switch off) when power is applied to the drive. When power is

applied for the first time, the motor is at the ambient temperature (30 °C).

2) Motor temperature is calculated using either the user-adjustable or automatically

calculated motor thermal time and motor load curve (see the figures below). The

load curve should be adjusted in case the ambient temperature exceeds 30 °C.

Use of the motor thermistor

It is possible to detect motor overtemperature by connecting a motor thermistor

(PTC) between the +24 V DC voltage supply offered by the drive and digital input

DI6. In normal motor operation temperature, the thermistor resistance should be less

than 1.5 kohm (current 5 mA). The drive stops the motor and gives a fault indication

if the thermistor resistance exceeds 4 kohm

.

The installation must meet the

regulations for protecting against contact.

Settings

Parameters

.

Note:

It is also possible to use the motor temperature measurement function. See

Motor temperature measurement through the standard I/O interface

on

Motor temperature measurement through an analogue I/O extension

on

Motor

100%

Temp.

63%

Motor thermal time

t

t

100%

50

100

150

Zero speed load

Motor load curve

Break point

Motor

Speed

Load

Current

(%)

Rise

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...