Actual signals and parameters

184

23.04

ACC

COMPENSATION

Defines the derivation time for acceleration/(deceleration) compensation. In

order to compensate inertia during acceleration a derivative of the reference is

added to the output of the speed controller. The principle of a derivative action

is described for parameter

Note:

As a general rule, set this parameter to the value between 50 … 100% of

the sum of the mechanical time constants of the motor and the driven machine.

(The speed controller Autotune Run does this automatically, see parameter

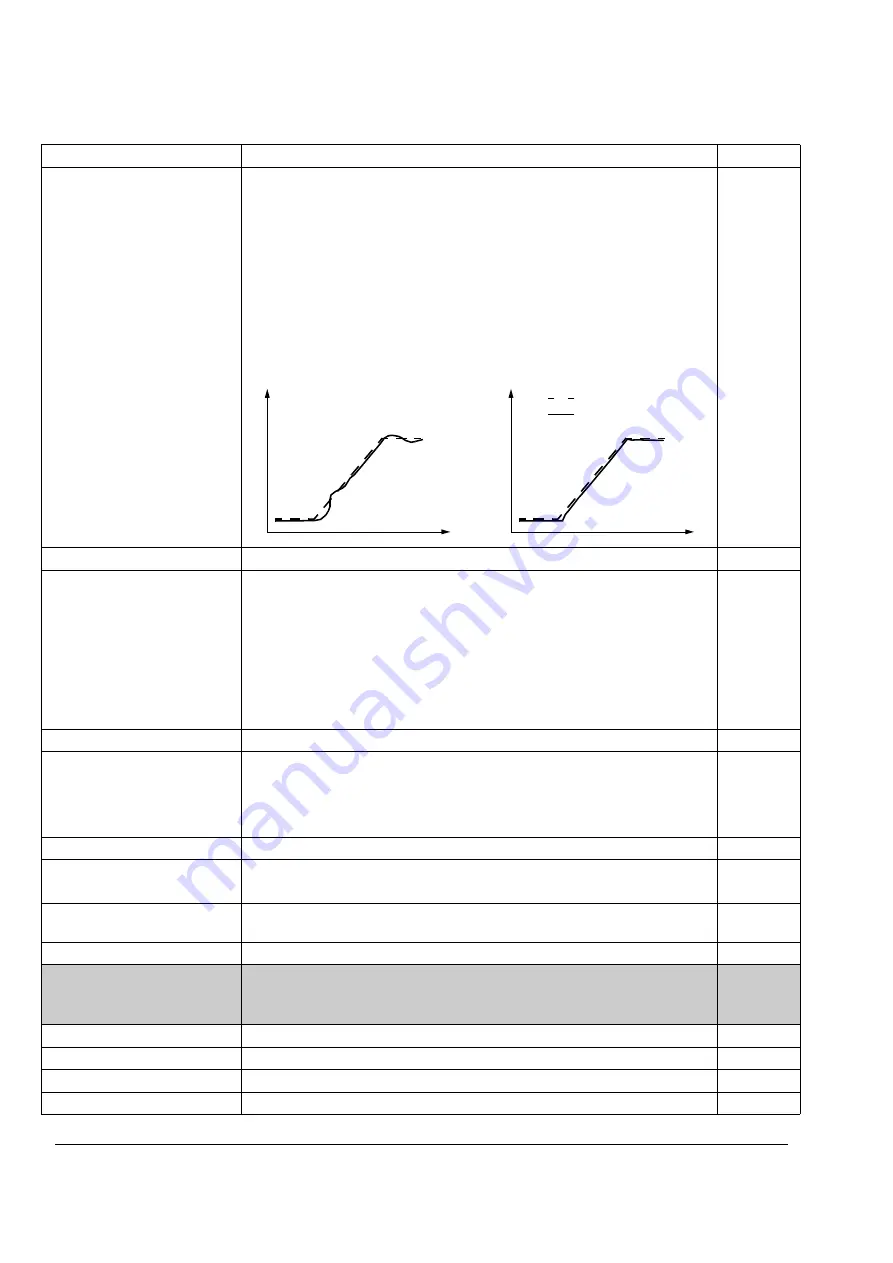

The figure below shows the speed responses when a high inertia load is

accelerated along a ramp.

0.00 … 999.98 s

Derivation time

0 … 9999

23.05

SLIP GAIN

Defines the slip gain for the motor slip compensation control. 100% means full

slip compensation; 0% means no slip compensation. The default value is

100%. Other values can be used if a static speed error is detected despite of

the full slip compensation.

Example:

1000 rpm constant speed reference is given to the drive. Despite of

the full slip compensation (SLIP GAIN = 100%), a manual tachometer

measurement from the motor axis gives a speed value of 998 rpm. The static

speed error is 1000 rpm - 998 rpm = 2 rpm. To compensate the error, the slip

gain should be increased. At the 106% gain value, no static speed error exists.

0.0 … 400.0%

Slip gain value.

0 … 400

23.06

AUTOTUNE RUN

Start automatic tuning of the speed controller. Instructions:

- Run the motor at a constant speed of 20 to 40% of the rated speed.

- Change the auto tuning parameter

Note:

The motor load must be connected to the motor.

NO

No auto tuning.

0

YES

Activates the speed controller auto tuning. Automatically reverts to NO.

65535

23.07

SP ACT FILT TIME

Defines the time constant of the actual speed filter, that is time within the actual

speed has reached 63% of the nominal speed.

0...1000000 ms

Time constant

1 = 1 ms

24 TORQUE CTRL

Torque control variables.

Visible only if Master/Follower is Active (parameter

and parameter

= DTC.

24.01

TORQ RAMP UP

Defines the torque reference ramp up time.

0.00 … 120.00 s

Time for the reference to increase from zero to the nominal motor torque.

0 … 12000

24.02

TORQ RAMP DOWN Defines the torque reference ramp down time.

0.00 … 120.00 s

Time for the reference to decrease from the nominal motor torque to zero.

0 … 12000

Index

Name/Selection

Description

FbEq

Speed reference

Actual speed

No Acceleration Compensation

Acceleration Compensation

t

t

%

%

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...