Actual signals and parameters

177

21 START/STOP

Start and stop modes of the motor.

21.01

START FUNCTION

Selects the motor starting method.

In special crane applications like slew-motion cranes, its possible to enable the

auto start function mode. For more information, contact your local ABB

representative.

CNST DC MAGN

In the crane applications, this parameter is fixed to CNST DC MAGN. Constant

DC magnetising is needed when constant pre-magnetising time is required

(For example, if the motor start must be simultaneous with a mechanical brake

release). CNST DC MAGN also guarantees the highest possible break-away

torque when the pre-magnetising time is set long enough. The pre-magnetising

time is defined with parameter

.

Note:

Starting to a rotating machine is not possible when DC magnetising is

selected.

Note:

DC magnetising cannot be selected if parameter

= SCALAR.

WARNING!

The drive will start after the set magnetising time has

passed although the motor magnetisation is not completed. Ensure

always in applications where a full break-away torque is essential, that

the constant magnetising time is long enough to allow generation of full

magnetisation and torque.

3

21.02

CONST MAGN TIME

Defines the magnetising time in the constant magnetising mode. See

parameter

. After the Start command, the drive automatically pre-

magnetises the motor the set time.

30.0 … 10000.0 ms

Magnetising time. To ensure full magnetising, set this value to the same value

as or higher than the rotor time constant. If not known, use the rule-of-thumb

value given in the table below:

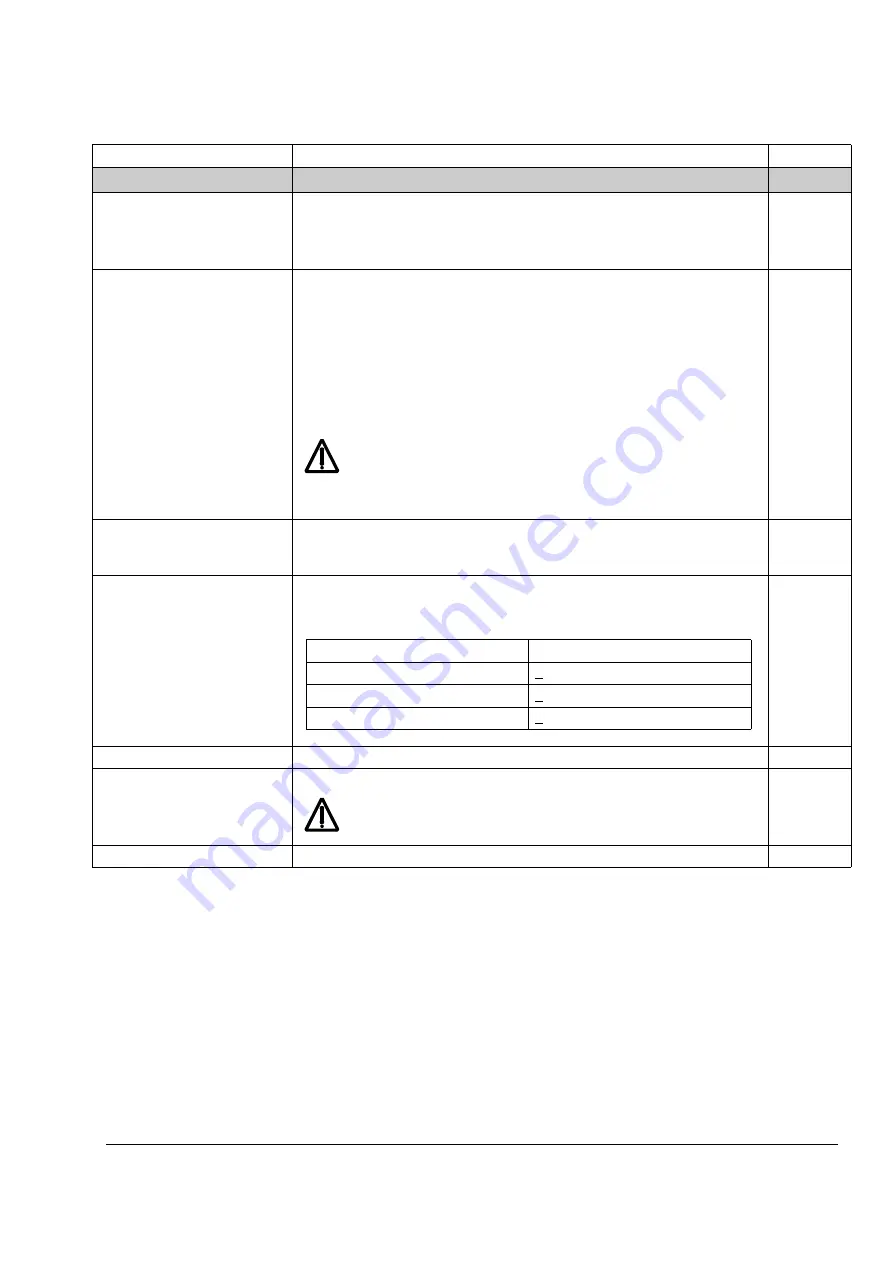

30 … 10000

21.03

STOP FUNCTION

Selects the motor stop function.

COAST

Stop by cutting of the motor power supply. The motor coasts to a stop.

WARNING!

If the mechanical brake control function is on, the

application program uses ramp stop in spite of the selection COAST

(see parameter group

).

1

RAMP

Stop along a ramp. See parameter group

.

2

Index

Name/Selection

Description

FbEq

Motor Rated Power

Constant Magnetising Time

< 10 kW

> 100 to 200 ms

10 to 200 kW

> 200 to 1000 ms

200 to 1000 kW

> 1000 to 2000 ms

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...