18

Any safety devices including low water cutoffs used in conjunction

with this boiler should receive periodic (every six months) inspection

to assure proper operation. A low water cutoff device of the float

type should be flushed every six months. Periodic checks, at least

twice a year, should be made for water leaks.

More frequent inspections may be necessary depending on water

conditions.

The boiler-mounted gas and electrical controls have been designed

to give both dependable service and long life. However, malfunction

can occur, as with any piece of equipment. It is therefore

recommended that all components be checked periodically by a

qualified service agent for proper operation.

RELIEF VALVE

Burn hazard.

Hot water discharge.

Keep clear of Pressure

Relief Valve discharge outlet.

The pressure relief valve must be manually operated at least

once a year. Caution should be taken to ensure that (1) no one

is in front of or around the outlet of the pressure relief valve

discharge line, and (2) the water manually discharged will not

cause any bodily injury or property damage because the water

may be extremely hot.

To test the relief valve, lift the lever at the end of the valve several

times, see Figure below. The valve should seat properly and

operate freely.

DISCHARGE

PIPE

RELIEF VALVE

FIGURE 4. - RELIEF VALVE

If after manually operating the valve, it fails to completely reset

and continues to release water, turn off power to the boiler at the

main disconnect switch or breaker. Close the cold water inlet to the

boiler and follow the draining instructions in this manual to drain

the boiler. Should the relief valve need to be replaced, call the toll

free phone number listed on the back of this manual for further

technical assistance.

COMBUSTION AIR FILTER

If the combustion air supply to the boiler contains dust, dirt, drywall

dust etc. a filter must be installed. An air filter is not supplied with

the boiler as shipped from the factory. The installer must provide a

filtering system in the air inlet to the boiler if dust, dirt or construction

dirt can be pulled into the boiler through the inlet air piping.

Periodically clean air filter per the manufacturer’s instructions.

BLOWER COMPARTMENT

The blower compartment should be cleaned annually to remove any

dirt and lint that may have accumulated in the compartment or on the

blower and motor. Buildups of dirt and lint on the blower and motor

can create excessive loads on the motor resulting in higher that

normal operating temperatures and possible shortened service life.

BURNER MAINTENANCE

Qualified servicers should follow this procedure when the boiler’s

burner needs cleaning.

1. Turn off the electrical power to the boiler and close the main

manual gas shutoff valve(s). Allow the boiler parts to cool before

disassembly.

2.

Loosen the flange and separate the gas train from the manifold

assembly.

3.

Separate the burner from the blower adapter by first removing

the four (4) bolts and subsequently, the blower gas kets. The

blower should be free to move at this point.

FoR DIRECT vENT UNITS: It is necessary to loosen and slide the

rubber coupling on the blower adaptor in order to move the blower.

4. loosen the seven bolts on the blower adapter at the base and

move the burner ground wire (Green) aside.

5. lift the blower adapter and remove the manifold assembly up

from the 6 studs located on the cover plate and remove the

burner gasket.

6. Remove any loose foreign material such as dust or lint with a

vacuum. Check all ports for blockage. Dislodge any foreign

material causing blockage. Remove any soot or carbon deposits

with a rag making sure to remove any lint left on the burner by

vacuuming again.

7. Reverse the steps to reassemble the unit.

8. Restore electrical power and gas supply to the boiler.

•

Put the boiler back in operation by following the lighting and

operating instructions in this manual.

•

Check for gas leaks and proper boiler and vent operation.

CONDENSATE REMOVAL SYSTEM

Due to the highly efficient operation of this unit, condensate is

formed during operation and must be removed by the conden sate

drain systems. Inspect the condensate drains and tubes at least

once a month and insure they will allow the free flow of condensate

at all times. The system must be inspected more frequently in

cold weather if the drain system is located in an area, such as

along the floor, where freezing tempera tures are likely to occur.

The condensate drain system must be protected against freezing.

Contact a qualified service agent to inspect and correct the condition

if freezing of the conden sate lines is a problem. The unit is equipped

with a blocked flue switch which will shut the unit off if condensate

is unable to drain and backs up in the unit. A blocked flue error will

appear when sufficient condensate accumulates for this condition.

The transparent drain lines and condensate drain on the bottom

of the vent collector should be visually inspected at one month

intervals for blockage, particularly in the areas of the loops in the

lines which trap a small amount of conden sate, and the exit point

of the vent collector drain. Conden sate in portions of the line other

than the loop area indicates a blockage in the drain line. Flush the

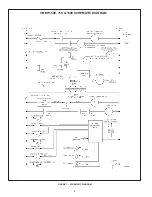

Содержание VF VB 1000

Страница 3: ...3 GENERAL SAFETY ...

Страница 6: ...6 CONNECTION DIAGRAM ...

Страница 7: ...7 ...

Страница 8: ...8 Figure 1 SCHEMATIC DIAGRAM VB VW 500 750 1000 SCHEMATIC DIAGRAM ...

Страница 9: ...9 LIGHTING OPERATION INSTRUCTIONS FOR MODELS VB VW 500 750 AND 1000 ...

Страница 20: ...20 notes ...

Страница 21: ...21 notes ...

Страница 22: ...22 notes ...