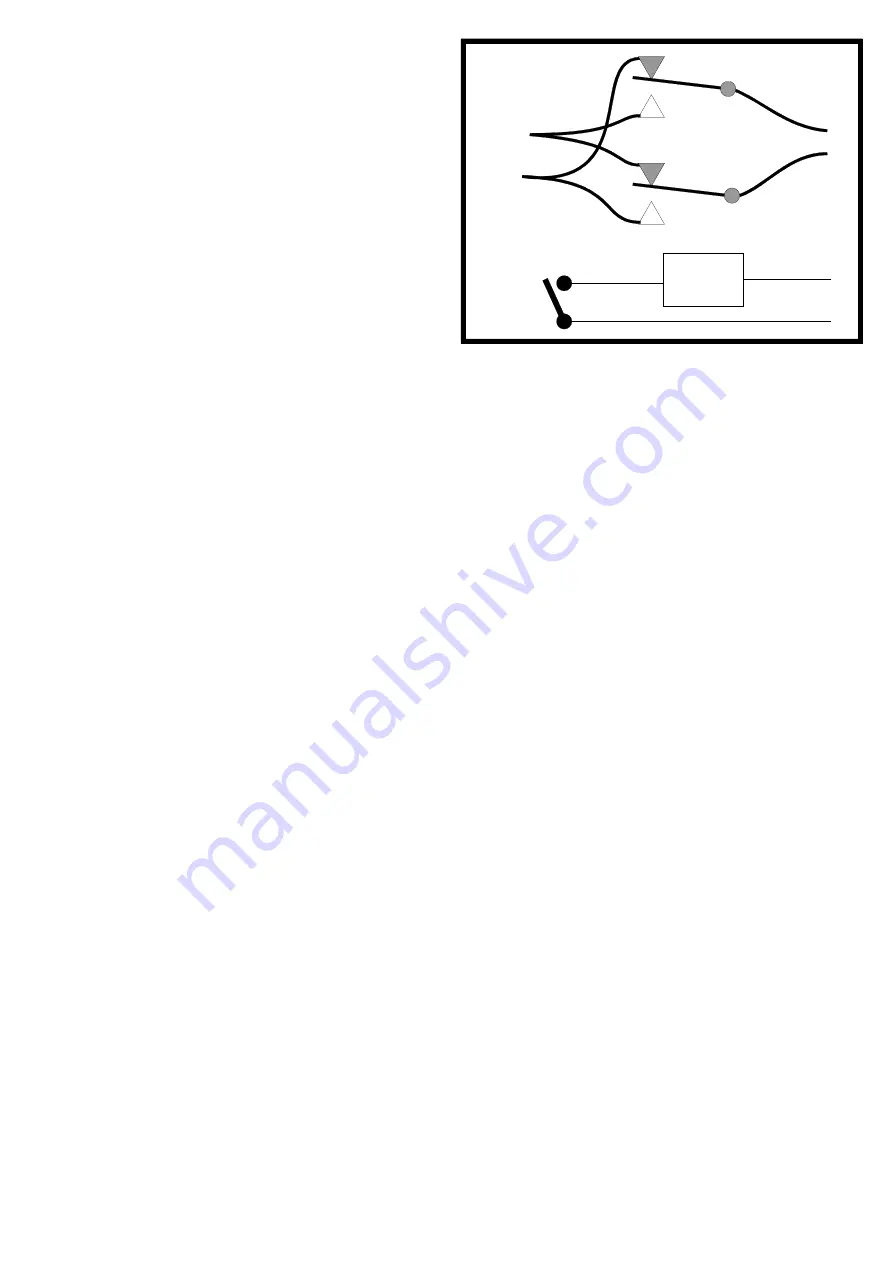

IMPORTANT: the switch or relay must not be

operated whilst the motor is running. To do so will

place great stress on the motor and mechanics. To

avoid this, put the reversing switch somewhere so

that it cannot easily be operated from the normal

driving position.

This is the main reason that reversing controllers are

available: they are configured so that reversing is safe

(to the controller) under all conditions, even when the

reversing switch is operated at full speed.

To motor

from Uni

n/c

n/o

n/c

n/o

c/o

c/o

Relay

coil

To

battery

Heat & Heatsinking

The rated current output of the controllers is with the

heatsink hot. When cold they will give considerably

more current. Thus the 35 amp version will in fact

give about 50 amps when cold. This is OK because

the MOSFETS used are rated at 60 amps continuous

with a case temperature of 25°C. As the MOSFETs

warm up their allowable current reduces so that at a

case temperature of 100 they can (only!) handle 45

amps continuous. The current limiting used in 4QD’s

controllers senses the MOSFET temperature and

automatically adjusts. However, running the

controllers at full current will cause speedy heating.

However, at some temperature (well above 100°C)

the MOSFETs will become unsafe, so we suggest

that, during initial use, you keep a note of the

heatsink temperature and, if it becomes much too hot

to touch, take appropriate steps, either by mounting

the Uni onto additional heatsinking or, better still, fit

a higher rated drive since heat is wasted battery

power and a larger drive will waste less. When using

an external heatsink remember that steel does not

conduct heat well: aluminium is far better.

For good heat conduction you must also use heatsink

compound between the Uni's on-board heatsink and

any external sink you fit.

I

nstead of a pot the input may be fed from a variable

voltage. 0v (common) to pin D, signal input (+ve) to

pin C.

Zero speed will be for zero voltage input and full

speed voltage may be adjusted (by the pre-set) to be

from 3v to above 20v.

If the input is a PWM signal, e.g. from a

microprocessor, and its amplitude may be above 5v,

then the pot fault protection circuit needs to be

deactivated. Two resistors are marked A and B on the

features diagram on page 3

To disable Pot fault, either disconnect A, or link out

(short circuit) resistor B.

Use as voltage follower