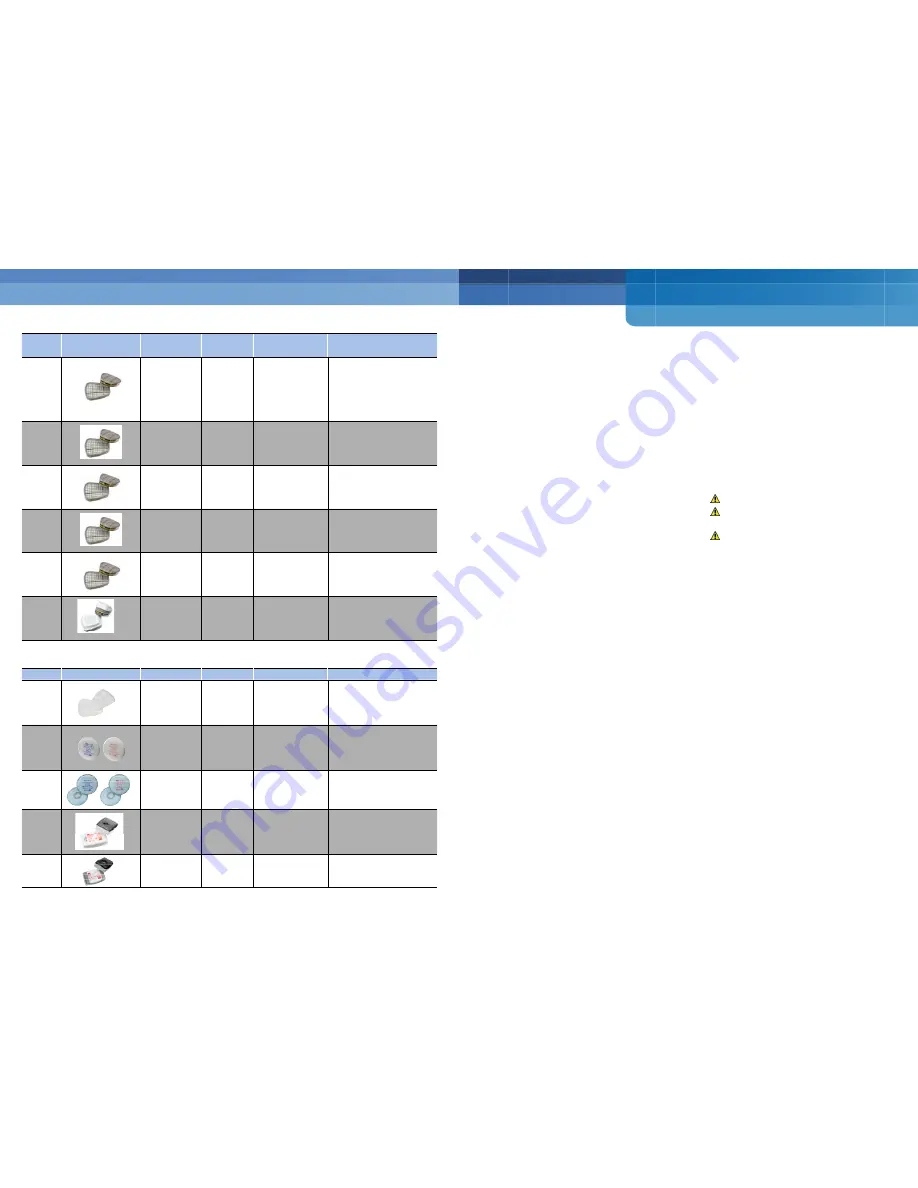

FILTER

IMAGE

STANDARD

CLASS

HAZARD

INDUSTRY

6051 (06911)

6055 (06915)

EN14387: 2004

+A1:2008

A1

A2

Organic Vapours

(b.pt. > 65°C)

- Anywhere conventional paints are used

(non-isocyanates, subject to usage condi-

tions)

- Vehicle manufacture

- Aircraft manufacture and refurbishment

- Boat Building

- Ink and dye manufacture and use

- Adhesive manufacture and use

- Paint and varnish manufacture

- Resin manufacture and use

6054

EN14387: 2004

+A1:2008

K1

Ammonia &

derivatives

- Manufacture and Maintenance of refrigera-

tion equipment

- Spraying and handling Agrochemicals

6057

EN14387: 2004

+A1:2008

ABE1

Combination organic vapours

(b.pt. >65ºC),

inorganic & acid gases

As 6051, but including:

- Electrolytic processes

- Acid Cleaning

- Metal Pickling

- Metal Etching

6059

EN14387: 2004

+A1:2008

ABEK1

Combination organic vapours

(b.pt. >65ºC), inorganic & acid

gases & Ammonia

As 6057 & 6054

6075

EN14387: 2004

+A1:2008

A1 +

Formaldehyde

Organic Vapours

(b.pt. >65ºC) &

Formaldehyde

As 6051 but also:

- Hospitals and Laboratories

6096

EN14387: 2004

+A1:2008

A1HgP3 R

Organic vapours (b.pt.

>65ºC), Mercury vapour,

Chlorine & Particulates

- Use of Mercury & Chlorine

- Particulate applications

FILTER

IMAGE

STANDARD

CLASS

HAZARD

INDUSTRY

5911

5925(06925)

5935

EN143:2000 +

A1:2006

P1

P2

P3

Particulates (Fine

Dusts & Mists)

- Pharmaceutical / Powdered Chemicals

- Construction / Quarrying

- Ceramics / Refractory materials

- Foundries

- Agriculture

- Woodworking

- Food Industry

2125

2135

EN143:2000 +

A1:2006

P2 R

P3 R

Particulates (Fine

Dusts & Mists)

- Pharmaceutical / Powdered Chemicals

- Construction / Quarrying

- Ceramics / Refractory materials

- Foundries

- Agriculture

- Woodworking

- Food Industry

2128

2138

EN143:2000 +

A1:2006

P2 R

P3 R

Particulates, Ozone &

nuisance levels of Organic

Vapours & Acid Gases

- Welding

- Paper Industry

- Brewing

- Chemical Processing

- Typical Smog

- Inks and Dyes

6035

EN143:2000 +

A1:2006

P3 R

Particulates (Fine

Dusts & Mists)

- Pharmaceutical / Powdered Chemicals

- Construction / Quarrying

- Ceramics / Refractory materials

- Foundries

- Agriculture

- Woodworking

- Food Industry

6038

EN143:2000 +

A1:2006

P3 R

Particulates, Hydrogen

Fluoride at 10 x TLV,

Nuisance levels of Organic

Vapours &

Acid Gases

As 6035 but also:

- Aluminium smelting

- Mining

Gas and Vapour Filters:

Particulate Filters:

Approvals

The 3M 6000 Series Respirators and 6000/5000/2000 Series

Filters have been shown to meet the Basic Safety Requirements

under Article 10 and 11 of the European Community Directive

89/686/EEC, and are thus CE-marked. These products were

examined at the design stage by: BSI Product Services, Kitemark

House, Maylands Avenue, Hemel Hempstead, Herts, HP2 4SQ,

England (Notified Body 0086).

Standards

These products have been tested to the relevant European Standards:

6000 Series Half Masks to EN140: 1998.

•

6000 Series Gas and Vapour filters to EN14387:2004 +

•

A1:2008

2000 and 5000 Series and 6035, 6038 Particulate filters to

•

EN143: 2000 + A1:2006.

Correct Usage

When the 6000 Series Half Mask is fitted with

Gas & Vapour Filters:

6000 Series gas and vapour filters, it may be used in

•

concentrations of gases or vapours (types specified by 3M) up

to 50 x the Threshold Limit Value (TLV) or 1000ppm (5000ppm

for 6055) whichever value is lower.

6075 offers protection against organic vapour (as above) and

•

10ppm formaldehyde only.

6000 Series gas and vapour filters should not be used to

•

protect the wearer against a gas or vapour that has poor

warning properties (smell or taste).

When the 6000 Series Half Mask is fitted with

Particulate Filters:

5911 filters may be used in concentrations of particulates up to

•

4 x TLV.

5925, 2125 or 2128 filters may be used in concentrations of

•

particulates up to 12 x TLV.

5935, 2135, 2138 or 6035, 6038 filters may be used in

•

concentrations of particulates up to 50 x TLV.

2128 and 2138 filters may be used to protect against ozone

•

up to 10 x TLV and offers relief from acid gases and organic

vapours at levels below the TLV.

6038 offers protection against 10 x TLV Hydrogen Fluoride

•

and offers relief from acid gases and organic vapours at levels

below the TLV.

Cleaning and Storage

Cleaning is recommended after each use.

Disassemble by removing the filters, head straps and other

1.

parts.

Clean and sanitize the mask (excluding filters) using 3M™

2.

105 Face Seal Cleaner or immersing in warm cleaning

solution and scrubbing with a soft brush until clean. Parts

may also be cleaned in a domestic washer.

Disinfect respirator by soaking in a solution of quaternary

3.

ammonium disinfectant or sodium hypochlorite (30 ML

household bleach in 7.5L of water) or other disinfectant.

Rinse in fresh, warm water and air-dry in noncontaminated

4.

atmospheres.

Water temperature should not exceed 50°C.

Do not use cleaning agents that contain lanolin

or other oils.

Do not autoclave. .

Use Limitations

These respirators do not supply oxygen. Do not use in oxygen

1.

deficient areas.*

Do not use for respiratory protection against atmospheric

2.

contaminants, which have poor warning properties, are

unknown or immediately dangerous to life and health, or

against chemicals, which generate high heats of reaction

with chemical filters. (The 3M S-200 Supplied-Air Respirator

System can be used against contaminants with poor warning

properties, subject to other use limitations).

Do not modify or alter this device.

3.

The assembled respirator may not provide a satisfactory face

4.

seal with certain physical characteristics (such as beards or

large side burns) resulting in leakage between the respirator

and the face. The user assumes all risks of bodily injury,

which may possibly result.

Do not use with unknown concentrations of contaminants.

5.

Do not use for escape purposes.

6.

Leave the work area immediately and check the integrity of

7.

the respirator and replace respirator and / or filters if:

Damage has occurred or is apparent.

•

Breathing becomes difficult or increased breathing

•

resistance occurs.

Dizziness or other distress occurs.

•

You taste or smell the contaminant or an irritation occurs.

•

Store this device in a sealed container away from

8.

contaminated areas when not in use.

Use strictly in accordance with respirator and filter

9.

user

instruction leaflet.

* 3M definition minimum 19.5% by volume oxygen