page

19

of

62

3DGence DOUBLE P255 | version 09.2018

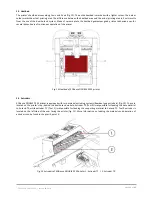

The information on consumables is displayed on the right side of the screen. TOOL 0 (on the left side) is the base material

(MODEL MATERIAL), while TOOL 1 (on the right side) is the support material (SUPPORT MATERIAL).

In the example shown in fig. 21, the material for TOOL 0 is loaded (this is indicated by icon next to the material spool graphic

symbol and the material loading temperature); UNLOAD MODEL MATERIAL option is active in this case. No material is loaded

for TOOL 1 (this is indicated by icon next to the material spool graphic symbol and NO MATERIAL message)

–

LOAD SUPPORT

MATERIAL option is active.

Load model material / load support material

–

choose this option to start the material loading manager (more information

can be found in chapter III, point 4.1).

Unload model material / unload support material

–

choose this option to start the material unloading manager (more

information can be found in chapter III, point 4.2).

Clean nozzles

–

if this option is selected, a test-extrusion of filament will be performed first by TOOL 0 and then by TOOL 1.

This option is particularly useful when the user has to change the material or remove the remains of old filament or if the

hotend has not been used for a long time and is slightly clogged. The automatic hotend cleaning assistant is available during

printing and in the idle mode.

Back

–

return to main MENU.

TUNE

- enables precise modifications of basic printing parameters (fig. 22).

Fig. 22 TUNE menu screen

Selecting a given parameter control option activates the value selection panel in the lower right corner of the screen. The value

can be modified using

–

/ + keys. The

RESET

key restores the default value.

Flow

–

percentage value of amount of fed material. 100% is the default amount of extruded material. The values should not

be changed by more than +/- 5%.

Speed

–

percentage value of printing speed. 100% is the default printing speed.

Tool 0 temp.

- this key makes it possible to set any temperature for the hotend of extruder 0 within the range of 185 - 270

⁰

C.

Tool 1 temp.

- this key makes it possible to set any temperature for the hotend of extruder 1 within the range of 185 - 270

⁰

C.

Heatbed temp.

–

this key makes it possible to set any temperature for the printer's heatbed within the range of 40-

160°C.

ATTENTION

: do not leave the hotends heated to high temperatures for more than 15 minutes if there is no material

flow. Otherwise, the material may degrade and block the hotend.

Fan speed

- this screen enables smooth adjustment of current power of the printout cooling fans within the range of 1% -

100%.

Auto fan on/off

–

the option is active by default (on). If this option is deactivated (off), the setting of the fans will be in

compliance with the power set in the printer and the commands resulting from the machine code will be ignored.

Back

–

return to main MENU.

Содержание DOUBLE P255

Страница 1: ...USER S MANUAL 3DGence DOUBLE P255...

Страница 27: ...page 27 of 62 3DGence DOUBLE P255 version 09 2018 Fig 33 Main menu structure in the idle mode...

Страница 28: ...page 28 of 62 3DGence DOUBLE P255 version 09 2018 Fig 34 Advanced menu structure...

Страница 29: ...page 29 of 62 3DGence DOUBLE P255 version 09 2018 Fig 35 Main menu structure in the working mode...