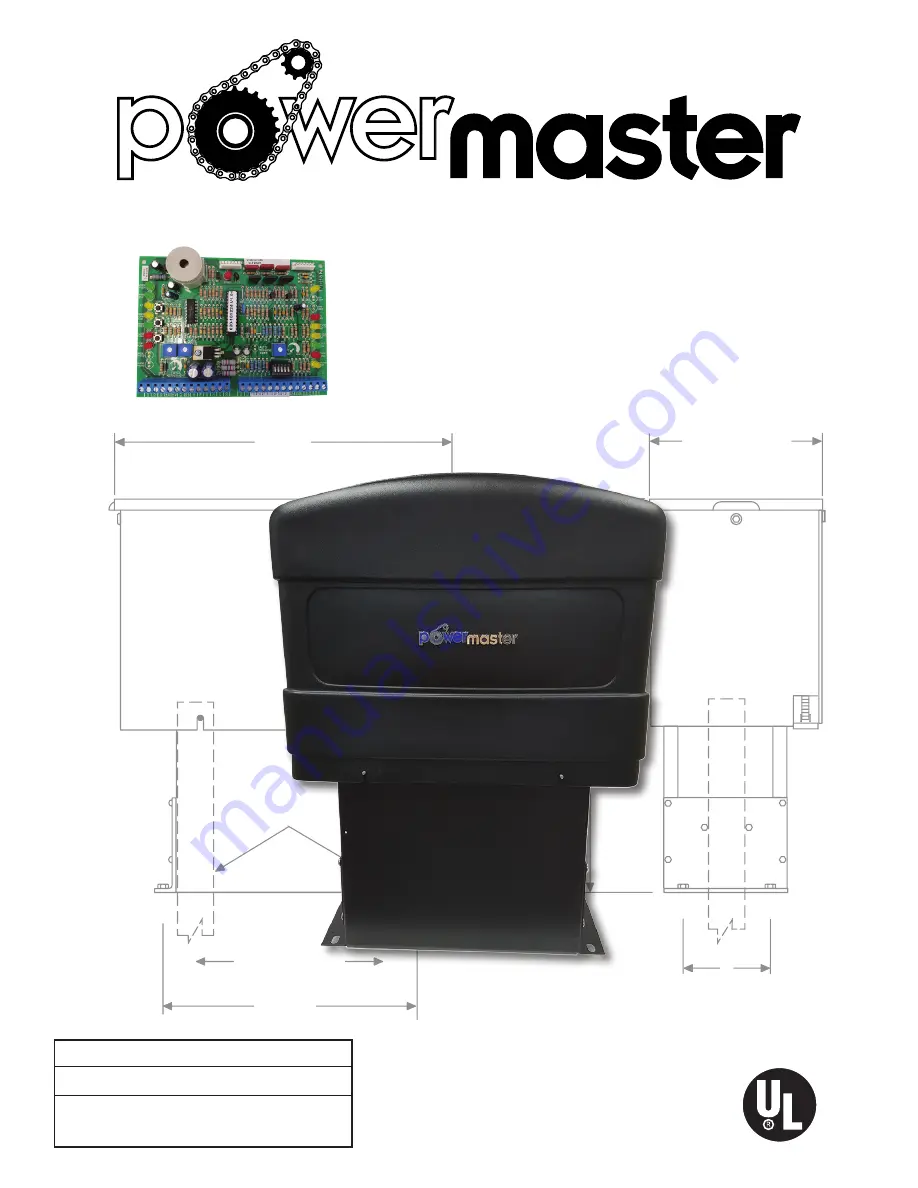

8"

14-1/2”

15-5/8”

22”

16-3/4”

27”

34”

3”O.D.

POST

INSTALLATION AND OWNER’S MANUAL

READ THIS MANUAL CAREFULLY

BEFORE INSTALLATION OR USE.

SAVE THESE INSTRUCTIONS.

Serial #:

Date Installed:

Your Dealer:

MODEL SG 2004

Slide Gate Operator

UL 325 and UL 991 Listed