Summary of Contents for Relay 2500

Page 4: ...This page intentionally left blank ...

Page 8: ...1 Safety In this section Safety Information 2 Warning Labels and Cautions 4 ...

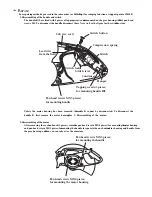

Page 12: ...2 Product Overview In this section Product Overview 6 Relay Inserter Component Overview 8 ...

Page 99: ...This page intentionally left blank ...

Page 171: ...This page intentionally left blank ...

Page 172: ...11 Specifications In this section Material Specifications 166 Inserter Specifications 172 ...