10

20

30

80

70

40

90

60

50

0

5

0

25

20

10

15

0-30mm

JEWELED

SHOCK-PROOF

WDI-3058SP

0.01mm

PP

-(:(/('

6+2&.3522)

:',63

PP

Minimize

10

20

30

80

70

40

90

60

50

0

5

0

25

20

10

15

0-30mm

JEWELED

SHOCK-PROOF

WDI-3058SP

0.01mm

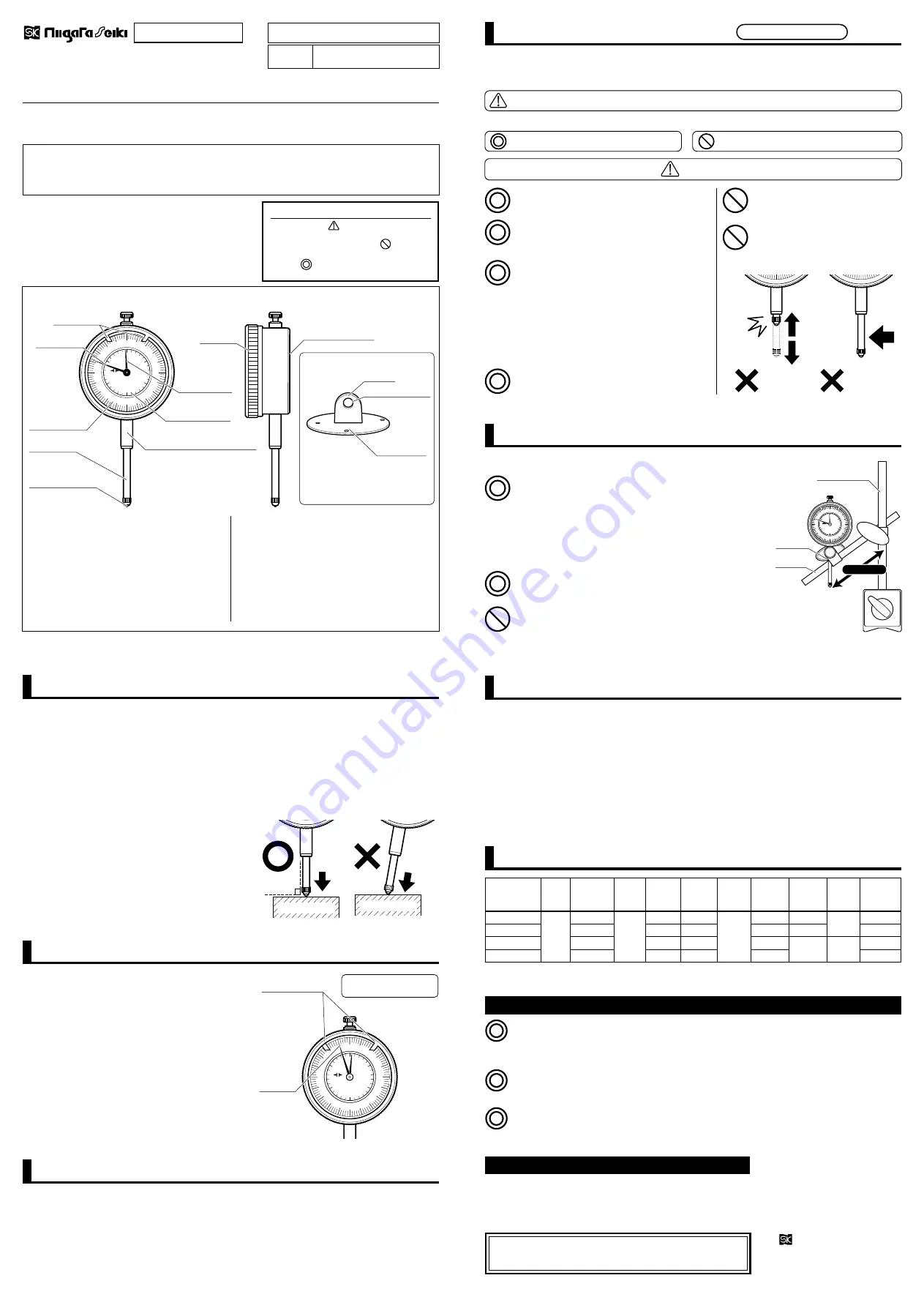

In this manual, indicates RISK OF

PERSONAL INJURY OR PROPERTY

DAMAGE if not followed. The symbol

indicates something which is PROHIBITED,

and the symbol Indicates REQUIRED

step or necessary condition.

For marking acceptance

range for Pass/Fail testing.

Shows measurement on

Main Scale. rotate Bezel (

⑨

)

to turn.

Pointer indicates Main Scale

x100

Each division is Main Scale

x100

For holding and mounting

Gauge.

①

Limit Markers ········

②

Pointer (Needle) ···

③

Main Scale ············

④

Revolution Counter ··

⑤

Rev. Counter Scale ··

⑥

Stem ·····················

Shaft moves up and down

with measurement.

Probe which contacts

workpiece.

Rotate to turn Main Scale

(

③

)

Standard back cover.

Alternate mounting point.

For mounting Gauge.

Accessory back cover for

mounting Gauge using Lug.

⑦

Spindle ·····················

⑧

Contact Point ···········

⑨

Bezel ························

⑩

Flat Rear Plate ·········

⑪

Lug ···························

⑫

Mounting Hole ·········

⑬

Rear Plate with Lug ··

LONG STROKE DIAL GAUGE

Model No.

INSTRUCTION MANUAL

Thank you for purchasing the Niigata Seiki Long Stroke Dial Gauge.

Used with a Magnetic Base or Indicator Stand, this gauge will show the difference in height

or position relative to a zero point set at a reference position.

・

Comparing to a master part during inspection.

・

Measuring machine tool positioning accuracy.

・

Measuring runout for rotary shafts.

・

Checking vise parallelism on milling machines.

・

Measuring flatness of surfaces and assemblies.

・

Confirming machine tool feed distance.

●

For safe and proper use of this product, please read this

instruction manual before use and follow the procedures

described. Please keep manual where it is accessible to

user for future reference.

●

Keep this manual with the instrument if transferred or

leased to a third party.

●

For inquiries about this product, please contact dealer or

Niigata Seiki at the address listed on the following page.

SAFETY NOTIFICATIONS

PROFESSIONAL

■

PARTS IDENTIFICATION & FUNCTION

■

APPLICATIONS

⑧

Contact Point

(Probe)

⑦

Spindle

⑥

Stem

②

Pointer

(Needle)

⑨

Bezel

Gauge Holder

Support

Arm

⑥

Stem

※

Model WDI-3058SP shown

⑪

Lug

⑫

Mounting Hole

(

6.5mm

)

⑬

Rear Plate

With Lug

⑩

Flat Rear plate

①

Limit

Markers

③

Main Scale

⑤

Rev. Counter

Scale

④

Revolution

Counter

WDI-3058SP

WDI-5058SP

WDI-8058SP

WDI-10078SP

●

Replacement Contact Point Part No.: DI-CP

WDI-3058SP

WDI-5058SP

WDI-8058SP

WDI-10078SP

7

9

11

15

≦

3.0

≦

3.5

≦

4.0

≦

4.5

1

30

50

80

100

0 -100

Model No.

Scale

g

g

g

g

210

270

290

530

Weight

(For Flat

Rear Plate)

Gradu-

ation

(mm)

Measurement

Range

(mm)

Hysteresis

Error

(

μ

m)

Measuring

Force

(N)

1

Revolution

(mm)

14

15

―

―

35

40

50

5

6

1/10 Rev

Indication

Error

(

μ

m)

Indication Error

over the Entire

Measuring

Range

(

μ

m)

SPECIFICATIONS

TROUBLESHOOTING

Remove any dust or dirt after use.

※

Do not lubricate.

・

Wipe any contamination from Spindle sliding surface using a dry cloth, or cloth moistened with

alcohol.

・

To clean other surfaces, wipe with a soft dry cloth, or a cloth moistened with a mild cleaner.

Check for wear of Contact Point.

・

Measurement accuracy will be affected by worn Contact Point. Regularly check for wear and

replace Contact Point if worn.

Store in provided case in a cool, dark, and dry location.

・

During storage, make sure there is no force on the Spindle (such as pushed in, or lateral force.)

・

Keep away from moisture and direct sunlight, and secure from unauthorized personnel.

■

Origin position shifts during measurement.

・

Temperature changes during measurement can cause repeatability error.

Please try the following solutions:

●

Use in location with constant temperature.

●

When taking measurements, periodically adjust zero point using a Master reference to correct for

temperature induced drift.

■

Measurement is not stable, or measurement accuracy is poor.

・

Contact Point may be worn.

Worn Contact Point will affect accuracy. Periodically check for wear, and replace if wear is affecting

measurement accuracy.

AFTER USE CARE, STORAGE

※

To Use the Rear Plate with Lug,

unscrew the standard Flat Rear

Plate screws, replace, and use

screws to secure.

[Accessories]

SAFETY PRECAUTIONS

PREPARATION - Mounting

Please Observe

Always follow the procedures specified below in order to prevent harm to yourself or others, and to

prevent damage to property.

HOW TO USE - Preparation

Dial gauge must be securely mounted such as on a comparator stand or magnetic base.

Please follow these guidelines.

Read the manual and follow all instructions.

・

Use of product other than as described in the

manual may cause accident.

Use only as Indicator Gauge.

・

Use for any purpose other than measuring may

damage or wear the instrument. Improper use

may also cause accident.

Use in an environment which meets the

following conditions:

●

Temperature within range of 0~40

°

C, humidity

30~70% (non-condensing.)

●

Location with minimal dust, oil, oil mist, and

protected from direct sunlight.

●

Location protected from use by children and

unauthorized people.

・

Use in location contrary to the above may cause

poor accuracy, damage to the product, or may

result in accident or injury.

Handle With Care.

・

Do not drop or subject to shock, do not place

under heavy objects. Damage may cause failure

or poor accuracy.

■

Content marked as follows indicates risk of injury or damage if not followed.

■

These symbols mark content that must be observed.

Caution

Indicates risk of personal injury or property damage if not followed.

WARNING

Denotes a prohibition – You MUST NOT do

Denotes a requirement – You MUST do

Do not disassemble or modify.

・

It may damage Gauge and cause

poor accuracy

Do not shock Spindle.

・

Rapid motion, or lateral force may

damage Gauge and cause poor

accuracy.

Make sure Gauge Holder is rigid.

・

Holder must be sufficiently secure to prevent deflection from

the weight of the Gauge.

・

Holder must be rigid enough to hold Gauge and not to lift

from measurement force.

・

Holder support arm should be as short as possible to prevent

deflection.

※

Deflection or lifting will cause measurement error such as

origin position error and inaccuracies in measured reading.

Dial Gauge must only be attached by Stem or Rear Lug.

・

Mounting of gauge by other than Stem or Lug will cause

inaccuracy and product damage.

During installation, do not over-tighten the Stem.

・

Excessive force on the Stem may cause Spindle to bind.

No Rapid

Motion

No Lateral

Force

CALIBRATION

1. Confirm that the Contact Point and Rear Cover are tightly fastened.

If loose, tighten Contact Point and Rear Plate Screws.

2. Attach to the Gauge Holder using the Stem or Rear Lug.

Mounting Gauge by other than Stem or Lug will cause inaccuracy and product damage.

3. Confirm that Pointer and Revolution Counter movement is smooth.

Using fingertip, gently press on Contact Point to move the Spindle up and down. Motion of Pointers

should be smooth. If it is not smooth make sure Stem is not clamped too tight, and adjust. Also make

sure Pointer is stable at set position.

4. Make sure Spindle axis is perpendicular to

measured surface.

If Spindle (Contact Point) is not at a right angle to

surface, Gauge will not operate properly and

measurement will be inaccurate. Always keep the

Spindle axis perpendicular.

※

When used to check parallelism of Milling Machine

vise, use a Magnetic Base to mount the Gauge

perpendicular to surface, and move it out of the way

during operation to prevent interference.

HOW TO USE - Comparison Measurements

1. Set Up Reference Part.

Carefully lift Spindle with fingertip, and, taking care

not to hit Spindle from the side, insert the Reference

Part or Master under Contact Point.

2. Set the Origin.

Adjust the gauge mount or rotate the Bezel to set the

Gauge to "0"

3. Remove Reference, and begin measurements.

Remove Reference or Master, careful not to

shock Spindle. Insert part to be measured and

read the measurement off the Scale.

※

Setting the Limit Markers

Limit Markers can be moved to show acceptance

range for measurements.

HOW TO USE - Parallelism, Flatness, Runout, etc.

1. Position Contact Point on surface.

Carefully lifting Spindle with fingertip, and taking care not to hit Spindle from the side, position

the surface to be measured under the Contact Point.

2. Set the Origin.

Adjust the gauge mount, or rotate the Bezel to set the Gauge to "0"

3. Read the scale as the measured part is moved.

Slowly move the part while monitoring the Pointer and reading the measurement.

Right

angle

※

Mounting Example

②

Pointer

①

Limit Markers

Ex.) Pass Range:

- 0.05 to +0.15mm

※

WDI-3058SP

・

WDI-5058SP

・

WDI-8058SP

………

8

mm

※

WDI-10078SP

……

10mm

Measured Object

Measured Object

0.01

Niigata Seiki Co., Ltd.

5-3-14, Tsukanome, Sanjo, Niigata, Japan, 955-0055

Tel. : +81-256-33-5522 Fax. : +81-256-33-5518

MAIL [email protected]

URL http://www.niigataseiki.co.jp

●

In order to maintain instrument accuracy, it is recommended

that accuracy is confirmed through calibration on a periodic

basis.

Wear of measuring surfaces from repeated use may affect

accuracy and periodic accuracy checks should be performed.

We provide calibration services. Please contact

agent in country of purchase to make arrangements.

Repeat-

ability

(

μ

m)