1

SL16365A

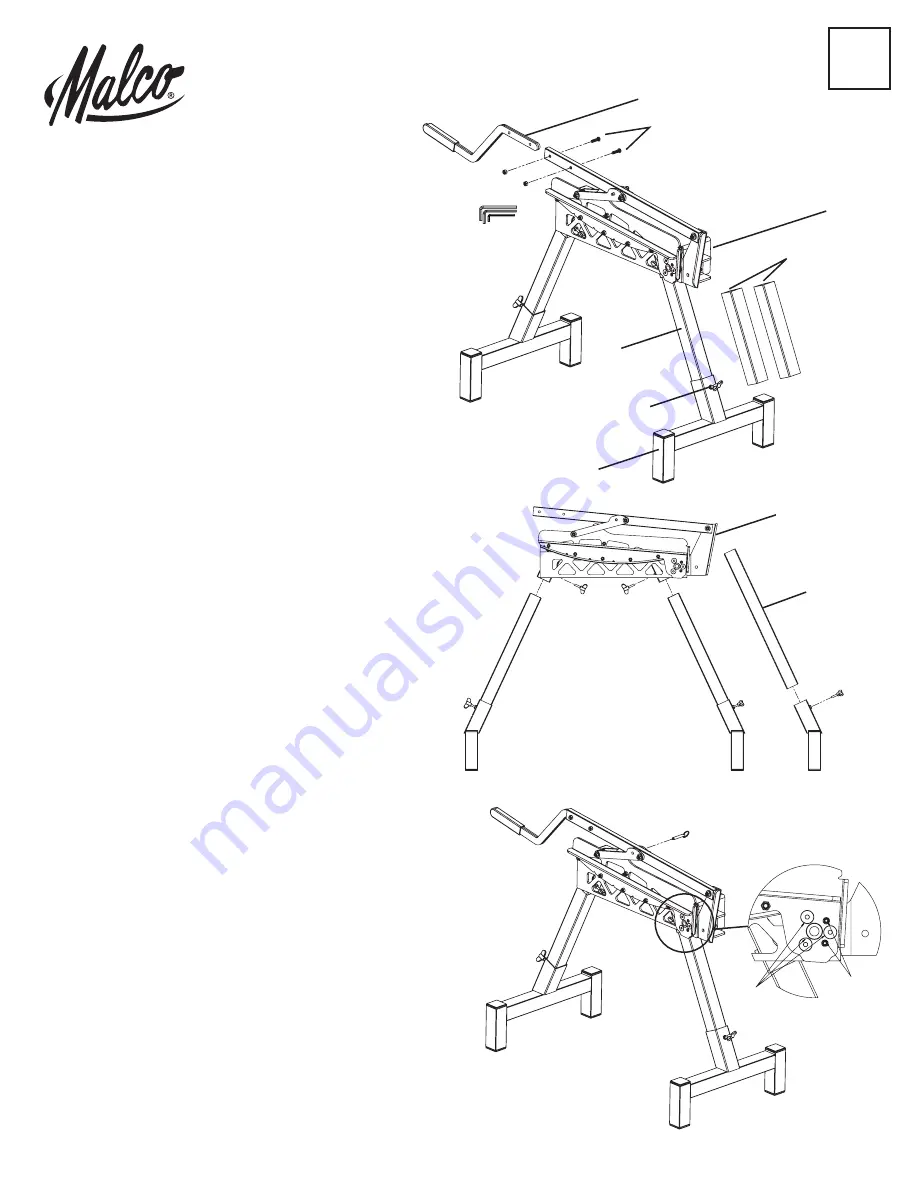

Set-up:

1.

A

-

Tool Body

B

-

Foot Assembly (2)

C

-

Short Legs (2)

D

-

Long Legs (2)

E

-

Wing Screws (4)

F

-

Handle (1)

G

-

Handle Fasteners (2 nuts and 2 bolts)

H

-

Hex Wrenches (3)

Instructions

2. Determine desired leg length and insert the appropriate

tube into each foot assembly

B

, Short Legs: Tube

C

, produce

a 21-1/4 inch working table height; Tube

D

, Long Legs, produce

a 29-1/4 inch working table height. Secure leg to foot with

included wing screws

E

.

3. Insert the other end of each leg/foot assembly into the

receivers on the main body of the tool

A

so that the feet sit

flush on the ground.

4. Secure the legs to tool body using the included wing screws

E

.

5. Insert the handle

F

into the tool as shown above and secure

using included fasteners

G

. Tighten fasteners until the handle

is securely attached.

6. The tool is now ready for use.

SCSRC1 / SCSRC1 EV

A

C or D

E

SCSRC1

SCSRC1EV

F

A

G

C

D

E

B

H

Blade & Die Lateral Adjustment:

The Malco Stone Coated Steel Roofing Cutter is factory adjusted

for optimum performance. In the unlikely event that this tool needs

adjusting to re-establish performance, follow instructions below.

1. Close the tool and insert the cross pin lock

J

.

2. Locate the 3-M10 flat head screws

K

around the pivot and, using an

included wrench, loosen these screws 1 to 1-1/2 turns.

3. Locate the 2-M8 set screws

L

around the pivot and, using an

included wrench, tighten these 2 screws a maximum of 1/4 turn each.

Make sure to tighten each screw the same amount.

4. Retighten the 3-M10 screws

K

very securely, making sure to cycle

around the screw pattern at least 2 times.

Cross Pin

K

J

L

EN