Operating manual

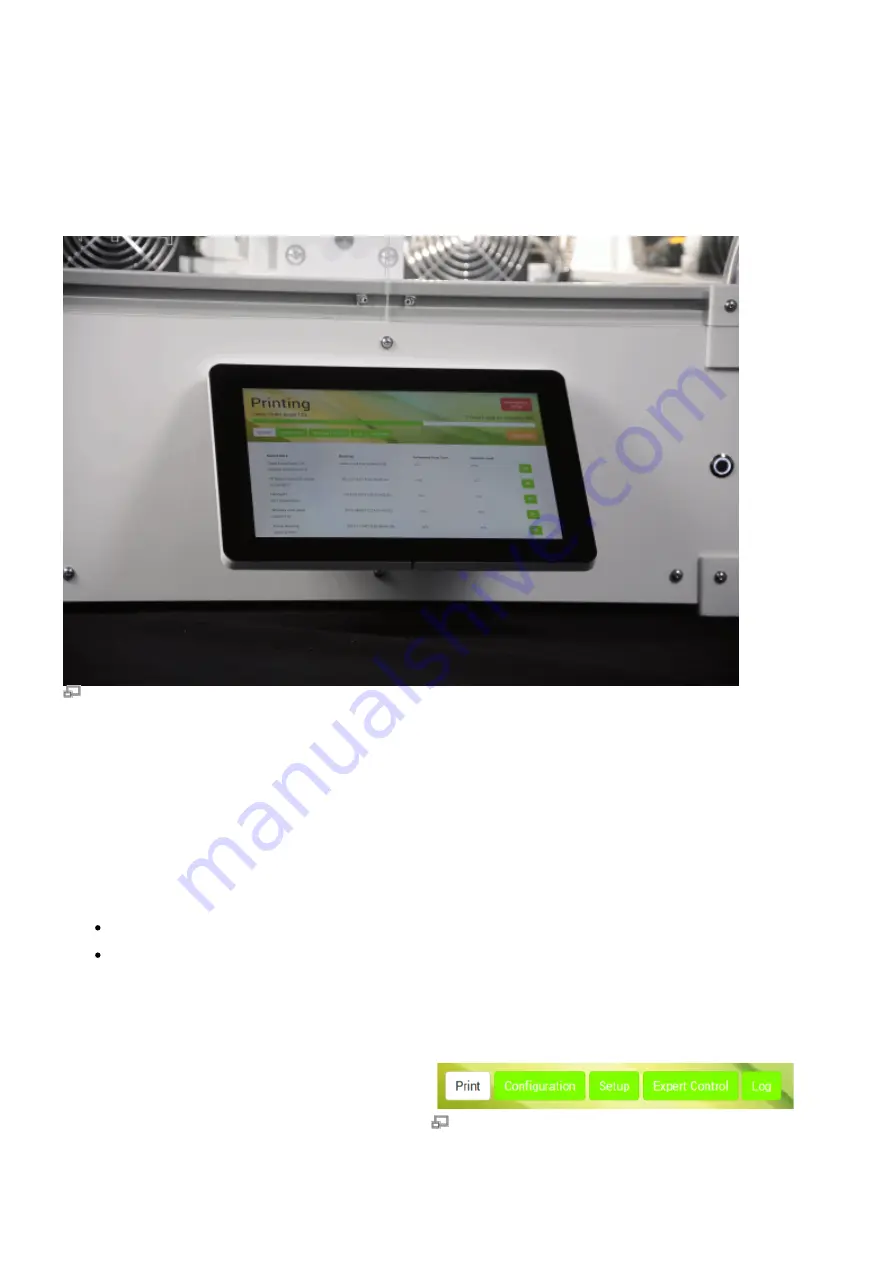

The high-resolution 10“-TFT touchscreen mounted at the front panel enables direct operation of the

RepRap Industrial.

This manual describes the

, the

the RepRapOnRails operating software and the all manual operating tasks that must be performed

during normal day-today use.

RepRapOnRails Software version lists

v1.1.0 (current)

v1.0.5 (05/2013 - 02/2015)

Operation

With the release of RepRapOnRails version

v1.1.0, all basic functions are now represented

on the start-up

The newly designed

menu

enables the operator to preselect temperature

The newly ordered operating menus of

RepRapOnRails v1.1.0.