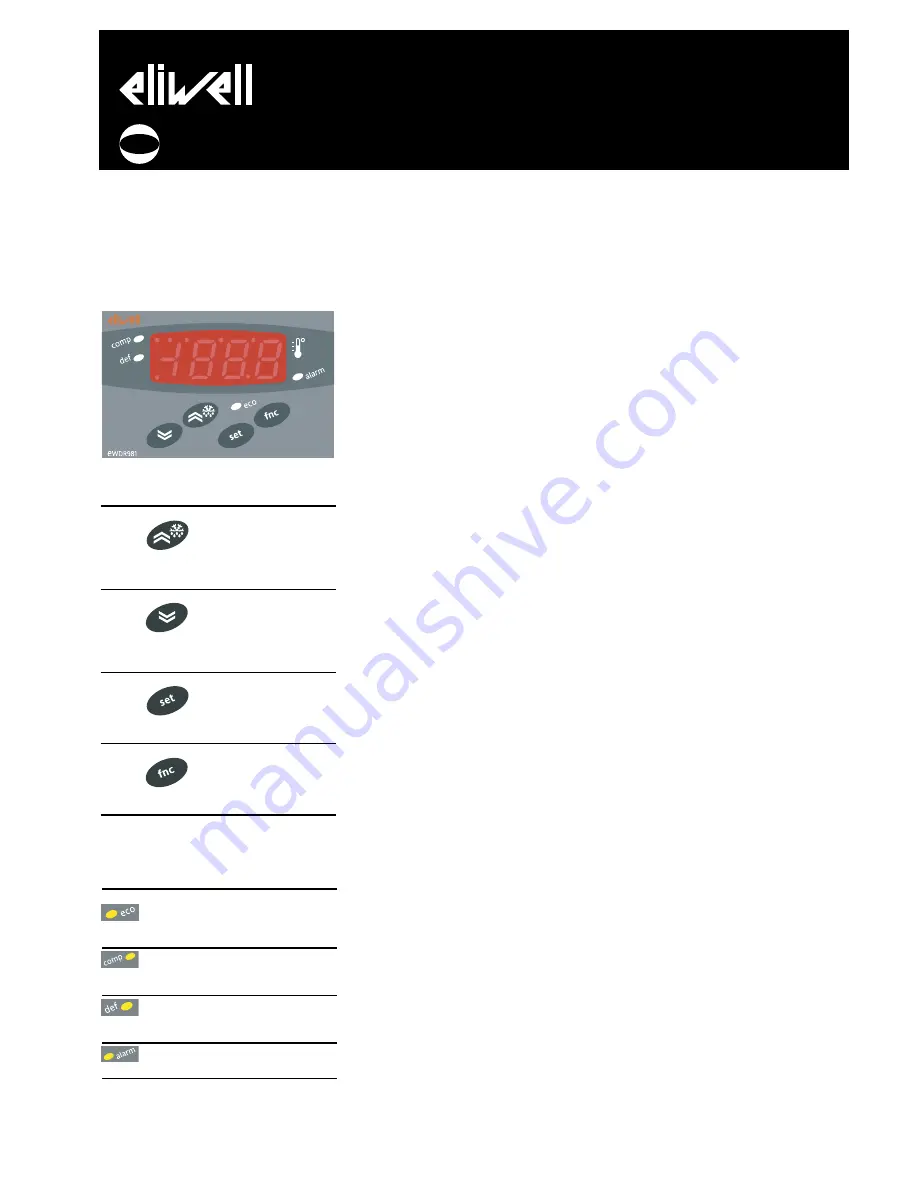

USER INTERFACE

The user interface has a 4 LED display to

indicate status and alarms and four buttons

for controlling instrument status and pro-

gramming.

KEYS

UP

Increase in value of

parameter

Menu scrolling and

activation of defrost

function

(Parameter programmable

H31)

DOWN

Decrease in value of

parameter

Menu scrolling and

activation of associated

function

(Parameter programmable

H32)

set

Access to different levels of

menu

Alarm display, set

point and probes

Access to programming of

parameters

fnc

Exit current level of

menu

Confirmation of value of para-

meter

(Parameter programmable

H33)

SIGNAL LED

The status of the external devices, functions

and controllers is described by the device

LEDs.

DISPLAY

This is used to display the inputs, the set

point, the parameters and related values,

alarms, functions and the status of the

device.

DESCRIPTION OF MENU

Access to both menus is controlled by

the ‘set’ button. If it is pressed and

immediately released, the ‘machine

status menu‘ is displayed. Hold the same

button down for 5 seconds to access the

‘parameter programming menu‘.

When one of the two menus has been

accessed, you can navigate between the

level 1 folders using the ‘UP’ and ‘DOWN’

buttons. The folders are opened by

pressing the ‘set’ button once. You can

now scroll through the contents of each

folder, modify it or use its functions.

You can exit each level of both menus in

three ways: using the ‘fnc’ button, if a

new value is confirmed by pressing the

‘set’ button or, when the time-out has

elapsed (15 seconds inactivity on the

device).

MACHINE STATUS MENU

The ‘machine status menu’ contains the

folders and basic information on the

device:

-AL: alarm folder

-SEt: Set point setting folder

-Pb1: ‘probe 1 value’ folder

-Pb3: ‘probe 3 value’ folder

If no alarms are present, the “SEt” label

is displayed. From here, you can scroll

down the other menu items using the

UP’ and ‘DOWN’ buttons.

Each folder can be accessed by pressing

the ‘set’ button once. Values are

modified using the ‘UP’ and ‘DOWN’

buttons and the ‘set’ button that

confirms the selected value and takes

you back to the higher level.

Setting the set point

Access the ‘machine status menu’. If no

alarms are present, the “SEt” label is

displayed. By pressing and immediately

releasing the ‘set’ button, the set point

value can be set using the UP’ and

‘DOWN’ buttons. Press and release the

‘set’ button again or press the ‘fnc’

button to go back to the main menu

level. The set point setting folder is also

closed when the time-out elapses.

Alarm on

If an alarm condition exists when the

Machine Status menu is accessed the

“ALfolder label appears.

PARAMETER PROGRAMMING MENU

Access the menu by pressing the ‘set’

button for at least 5 seconds.

The menu structure enables all

parameter folders to be divided into two

levels.

All the level 1 folders can be accessed

by entering the password ‘PA1’.

Scroll down the level 1 folders using the

‘UP’ and ‘DOWN’ buttons. Press and

release the ‘set’ button next to the

selected label to access the parameters.

Scroll through the labels in the folder

using the ‘UP’ and ‘DOWN’ buttons,

press ‘set’ to display the current value of

the selected parameter, use the ‘UP’ and

‘DOWN’ buttons and set the required

value by pressing ‘set’.

To access the level 2 folders in the ‘Cnf’

folder, select the ‘PA2’ label, enter the

password ‘PA2’ and confirm with the ‘set’

button. All the parameters that cannot

be changed at level 1 are in this level.

NOTE: Level 1 parameters will only be

displayed if you quit the ‘parameter

programming menu’ and repeat the

steps for manipulation of level 1

folders.

The steps to follow for manipulation of

level 2 parameters are the same as those

NOTE: It is strongly recommended

that the instrument is switched off

and on again each time parameter

configuration is changed in order to

prevent malfunctioning of the

configuration and/or ongoing timings.

PASSWORD

The passwords “PA1and “PA2” are used

to access level 1 and level 2 parameters.

To change them and assign them the

desired value, access the ‘parameter

programming menu’ in the “diS” label

folder.

The password is requested:

- PA1 when entering the ‘parameter

programming menu’;

- PA2 in the “Cnf” folder containing the

level 1 parameters.

USING COPY CARD

The Copy card function can be used to

upload and download parameter maps

of one or more of the same type of

instrument.

The accessory is connected to the device

using the special TTL serial port on the

instrument. The Copy card can be used

for the following functions:

EWDR 981

electronic controllers for refrigeration units

cod. 9IS43091

rel. 3/05

GB

LED

Description

Indication

reduced set point

Lights up when

inserted

LED set point is dis-

played, blinking

when reduced set

point is inserted

compressor LED

‘on’ with LED on.

Blinking for delay,

protection or acti-

vation blocked

defrost LED

‘on’ during defrost-

ing. Blinking when

activated manually

or by digital input

alarm LED

‘on’ if alarm is pre-

sent. Blinking for

silenced

alarm decimal point

‘on’ to indicate of

voltage when on

stand-by and dis-

play ‘off’