CAUTION: Read All Instructions Before Operating Equipment

308 Industrial Park Road

Starkville, MS 39759 USA

Tel: 662-323-9538 Fax: 662-323-6551

VERSION 1A

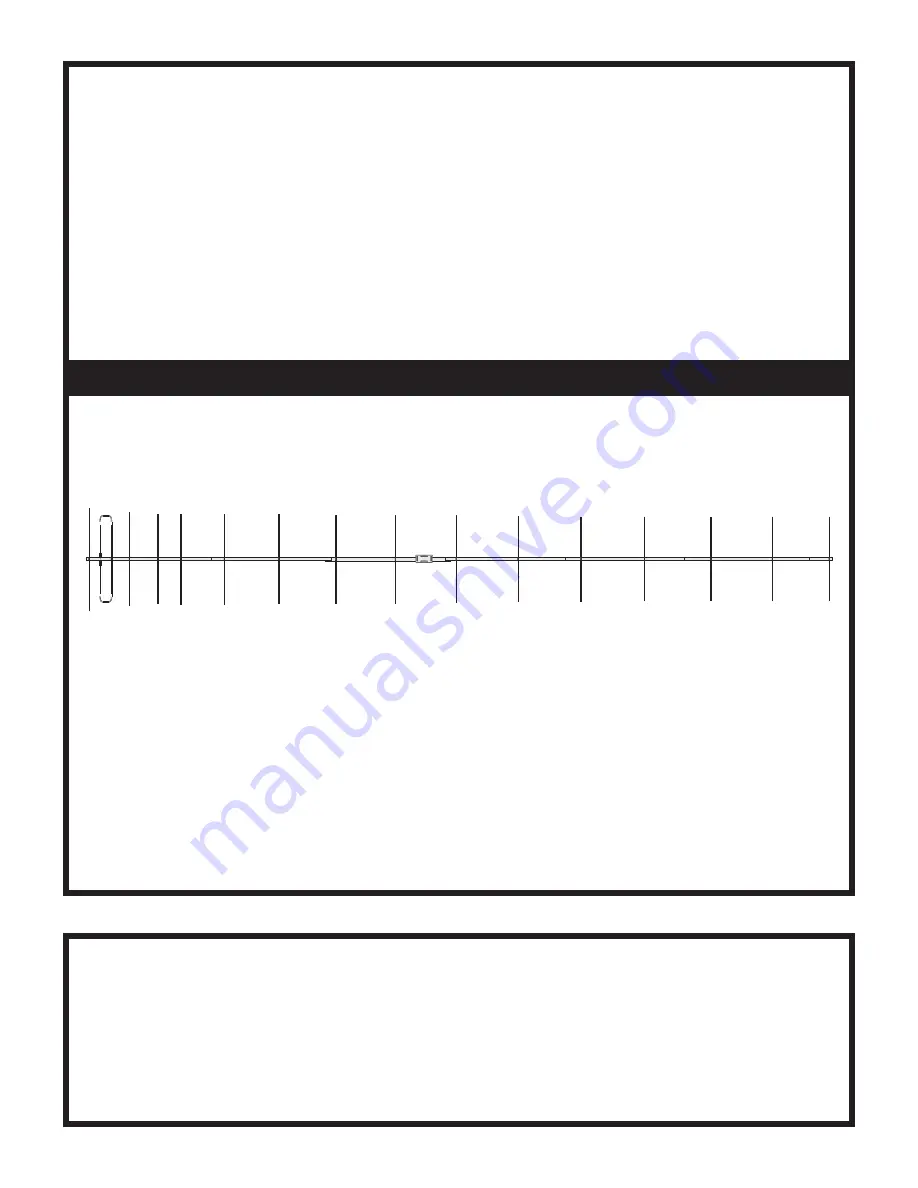

LFA-2M16EL

16 Element Loop Feed Beam

For 2 Meters

INSTRUCTION MANUAL

111

Cushcraft

Amateur Radio Antennas

Cushcraft

Amateur Radio Antennas