Reviews:

No comments

Related manuals for 351.181720

AN922

Brand: Makita Pages: 3

AG125

Brand: Makita Pages: 3

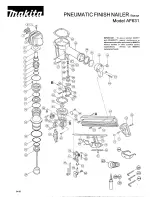

AF631

Brand: Makita Pages: 2

AF503

Brand: Makita Pages: 32

DX 450

Brand: Hilti Pages: 144

EG130

Brand: Rapid Pages: 20

2000TN

Brand: Powernail Pages: 12

17220

Brand: Mannesmann Pages: 28

Airtac PB131

Brand: Rapid Pages: 116

90.25 CLM

Brand: Omer Pages: 2

DPT350RFJ

Brand: Makita Pages: 48

KJ45

Brand: FAR Pages: 44

RP9061-2/LT50

Brand: Rongpeng Pages: 7

F30F

Brand: Rongpeng Pages: 8

ECAR-S

Brand: Everwin Pages: 7

PN70CL

Brand: Everwin Pages: 12

FSN2283 Series

Brand: Everwin Pages: 12

BX 3-ME

Brand: Hilti Pages: 438