Part # MSP-DCCPPNR

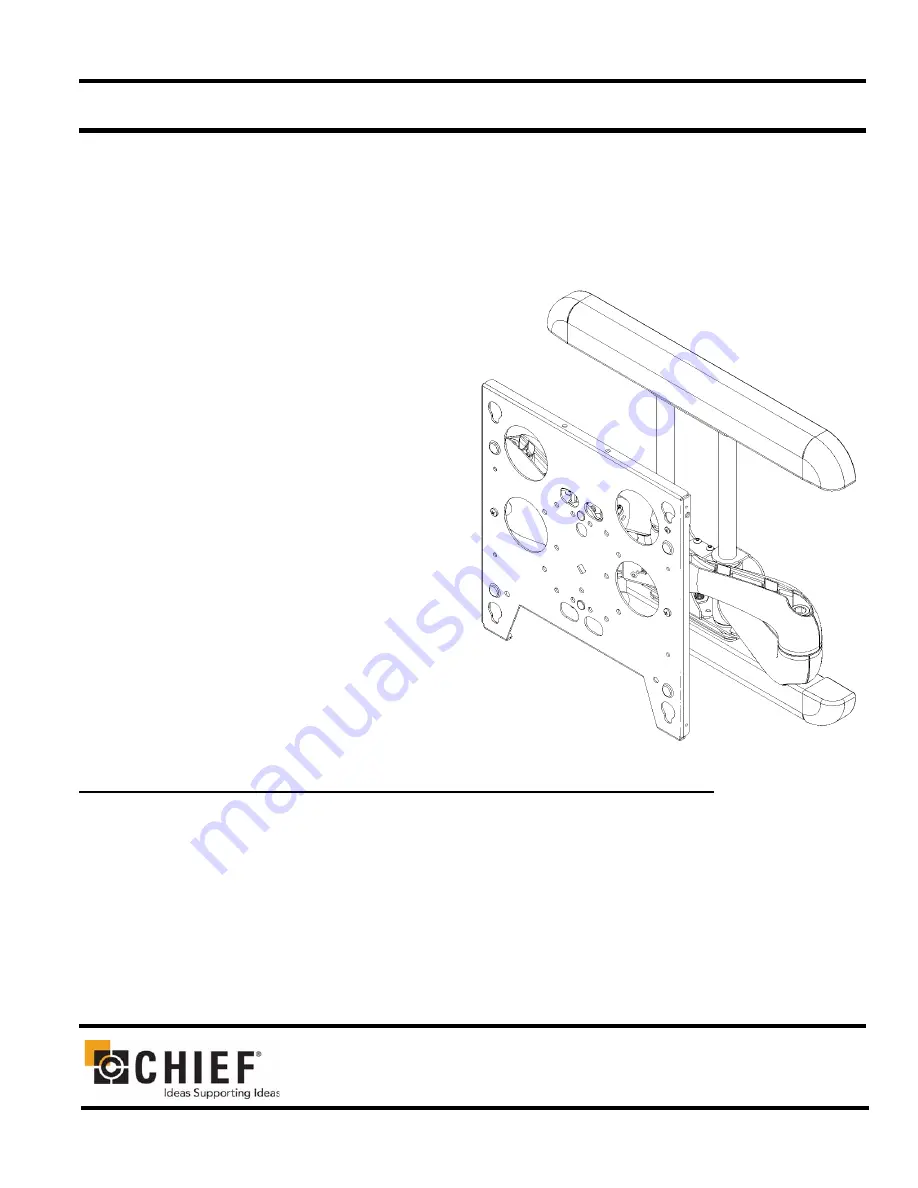

Large Flat Panel Dual Arm Wall Mount

The MSP-DCCPPNR is wall-mounted, rugged, versa-

tile, and installer-friendly. The mount is compatible

with the standard (14” x 14”) PSB interface bracket in

which a display can be mounted in either the land-

scape or portrait position on the mount.

The dual arms on the MSP-DCCPPNR:

•

Extend from the wall 24-7/8” in length

•

Pivot up to 90º left or right of center

The standard mount is shipped with the support posts

for the dual arms centered in the mount. The support

posts can be moved laterally right or left of center to

readily accommodate sites with limited wall space.

The mount also has two inches of height adjustment.

The tilt range for the display is 5º up and 15º down.

The MSP-DCCPPNR was designed for fast installa-

tion. After drawing the plumb line and installing the

two top lag bolts into the dual wall studs, the installer

hangs the mount on its top bracket and installs two lag

bolts in the bottom bracket. Next, the installer makes

the height adjustment, mounts the display, and con-

nects the power/audio/video cables, which are

diverted into the built-in path in the swing-out arms.

After making the lateral, rotational, and tilt adjust-

ments, the installation process is complete.

BEFORE YOU BEGIN

•

Caution: To prevent damage to the PNR, which could affect or void the Factory warranty, and to the equip-

ment that will be attached to it, thoroughly study all instructions and illustrations before you begin the

installation. Pay particular attention to the “Important Warnings and Cautions” on Page 2.

•

The combined weight of the components installed on the PNR must not exceed 200 lbs. (90.72kg).

•

The PNR wall mount must be installed on dual wall studs or supporting framework. The wall to which the PNR is

anchored must be capable of supporting

five times

the total weight of the mount and all attached equipment.

•

If a defect is discovered after Dell’s initial 21 day Customer Satisfaction period, Chief Mfg. will, at its option, repair

or replace the product at no charge provided it is returned during the warranty period. Please note contact informa-

tion for Chief Mfg. listed below:

CHIEF MANUFACTURING INC.

1-800-582-6480

952-894-6280 FAX 952-894-6918

8401 EAGLE CREEK PARKWAY, STE. 700

SAVAGE, MINNESOTA 55378 USA

PART NO. 8805-000146 (Rev. B)

2005 Chief Manufacturing

www.chiefmfg.com

10/05

I N S T A L L A T I O N I N S T R U C T I O N S

Summary of Contents for MSP-DCCPPNR

Page 3: ...3 Installation Instructions MSP DCCPPNR DIMENSIONAL DRAWING ...

Page 14: ......