Classification: Avery Dennison - Public

Operators and Service Manual

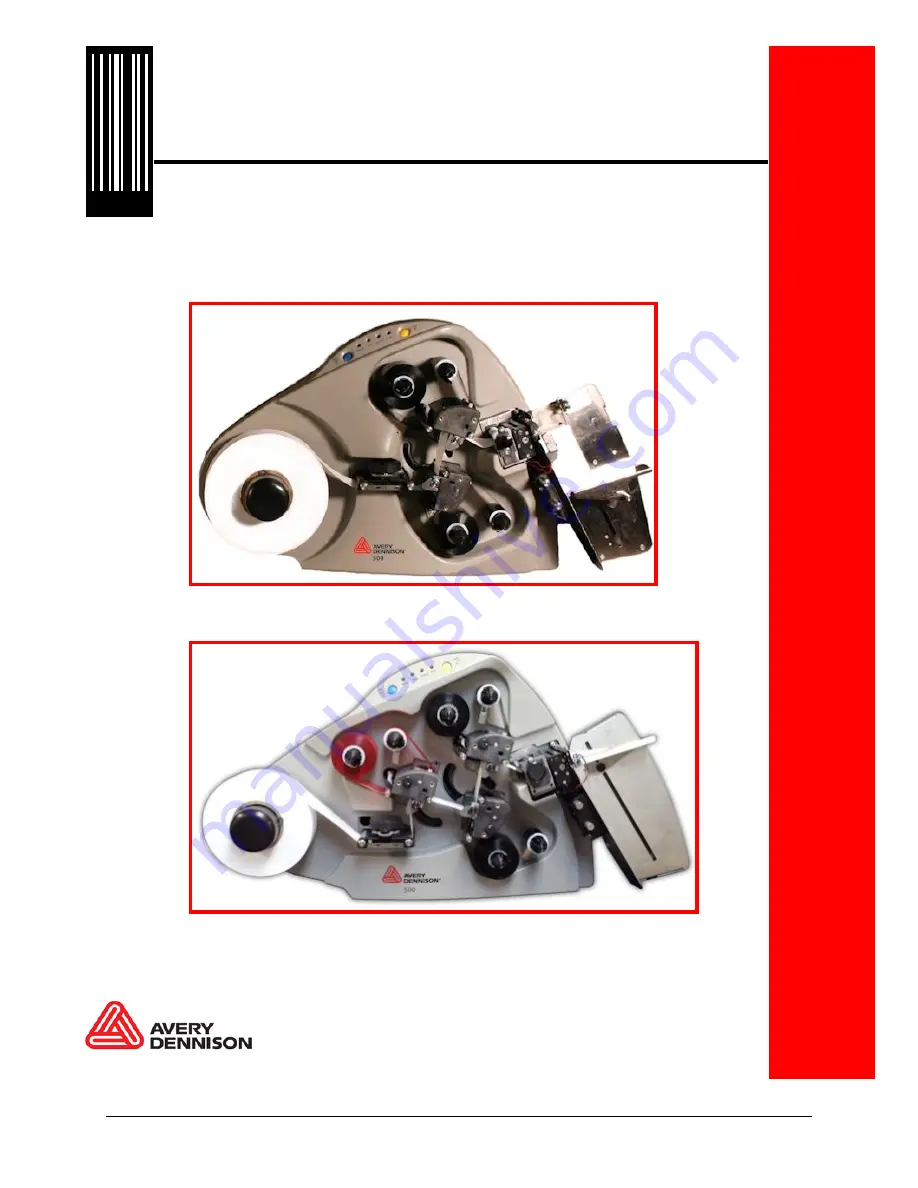

Avery Dennison

SNAP

TM

500 Thermal Printer, Gen 1 and Gen 2

300dpi: 2/1 2/0 1/1 1/0

600dpi: 1/1 2/1

Gen 1

– 2 heads

Gen 2

– 1, 2, or 3 heads

05631398 Rev 5.2 02/17

Original Instructions

© 2017 Avery Dennison Corp. All rights reserved

028028