Adjust-A-Sink® System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 |

www.adjustasink.com

1 of 25

3/2023

There are three keys to a successful installation:

1.

Locate the drain rough-in along the centerline of the installed sink system. Hair interceptors

need to be aligned straight back to not interfere with the moving shroud when fully assembled.

If the rough-in is not on center and you are installing on a cabinet – correct the offset within the

cabinet bulkhead space.

2.

This unit requires both supply lines installed on the left of the drain connection.

3.

Secure the telescoping drain and verify the full range of vertical motion of the sink FIRST,

then connect the trap between the drain and rough-in. You may need to construct a trap from

components to get the elevations to align.

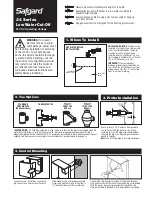

Your system comes in two boxes, what is

included:

Shampoo Bowl box

(left in photo)

:

24”x26”x15”, 36

lbs. Contains the 3050 bowl, bowl, fixtures, spray hose,

and vacuum breaker or backflow preventer.

E140 box:

14” x 28” x 39”, 95 lbs. Contains the main

unit lift system, panels and shrouds.

Required Hardware/Supplies Not Included:

1 ½” UPC Listed P-Trap, 90 Degree Supply line shut-off valves,

Lag Bolts and/or 5/16” Bolts-Washers-Nuts (if mounting to cabinet), Plumbing Supplies such as Plumbers Putty,

Sealant, Silicone Caulk, etc.

For replacement part orders or further information please contact Customer Service at: (612) 238-4600

Local Building Codes May Apply. Adjust-a-Sink® is a registered trademark of Accessible Systems, Inc.

E140 SERIES

**INSTALLATION INSTRUCTIONS**