Reviews:

No comments

Related manuals for ESS R050100

Premier

Brand: ABSCO SHEDS Pages: 21

CI 3000

Brand: ECKELMANN Pages: 134

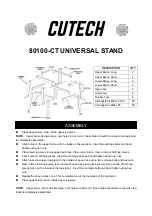

80100-CT

Brand: Cutech Pages: 2

5BIG NAS PRO

Brand: LaCie Pages: 22

BLACKOUT WINDOW STORAGE SYSTEM

Brand: REBEL OFF ROAD Pages: 9

REPLACE TAPE DRIVE IN STORAGELOADER VXA...

Brand: Tandberg Data Pages: 10

Expansion 750GB

Brand: Seagate Pages: 1

GD-MS013

Brand: Argus Pages: 24

PG-HDH61A

Brand: Fujitsu Pages: 12

PG-HD6G1C

Brand: Fujitsu Pages: 16

MPG3xxxAT

Brand: Fujitsu Pages: 201

PG-HD2E4H

Brand: Fujitsu Pages: 14

MPC3045AH

Brand: Fujitsu Pages: 185

MPC3032AT

Brand: Fujitsu Pages: 179

MPA3017AT

Brand: Fujitsu Pages: 176

MPD3091AH

Brand: Fujitsu Pages: 191

MJA2080BH

Brand: Fujitsu Pages: 320

MPD3043AT

Brand: Fujitsu Pages: 191