Absco Industries

Assembly Instruction Manual

LARGE GABLE SHED

N3/C1 FRAME KIT

FOR WORKSHOP & UTILITY MODELS

Model: CYCWKUTK

02/03/21

1.3

1

DOWNLOAD

OUR APP FOR

ASSEMBLY

VIDEOS

LEAVE A REVIEW

Tell us about your experience and

receive a $20 Coles Gift Card.

Visit

www.abscosheds.com.au/review

AU: 1800 029 701

NZ: 0800 466 444

www.abscosheds.com.au

This kit is applicable to the following sheds:

The addition of this frame kit will increase the

wind rating of the specified sheds to

Wind rating: N3/C1 as per AS4055-2012.

Suitable for specific cyclonic regions

60303WK

52233WK

45302WK

45232WK

3060UTK

3052UTK

3045UTK

WARNING: This shed must be anchored to a

100mm thick concrete slab with the concrete

anchors supplied.

Failure to do so will result in the shed not

having the structural integrity required to

endure a severe storms or cyclonic event.

WARNING: Doors must remain closed with

all padbolts properly secured during severe

storms or cyclonic event.

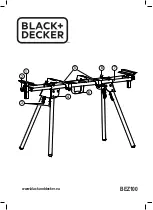

View of frame kit applied to

60303WK

Where information conflicts with the original

instruction manual, this document is to be

referenced.

This instruction manual is to be used during

the initial construction of the structure.