Reviews:

No comments

Related manuals for ADVAC 03

1652C

Brand: Fluke Pages: 66

The Hook

Brand: Power Probe Pages: 22

ETR4

Brand: Eaton Pages: 3

FRCdM-Type B

Brand: Eaton Pages: 2

T7-T7M-X1

Brand: ABB Pages: 12

SACE Tmax T6

Brand: ABB Pages: 5

S800U

Brand: ABB Pages: 2

S201-K5

Brand: ABB Pages: 6

Record Plus FB100

Brand: ABB Pages: 4

S 280 UC Series

Brand: ABB Pages: 16

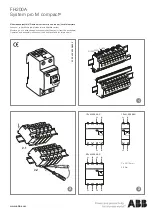

FH200A

Brand: ABB Pages: 2

F204 125 Series

Brand: ABB Pages: 2

Infinity NE-S

Brand: ABB Pages: 11

GE Power Break II GEH6271

Brand: ABB Pages: 10

Emax Series

Brand: ABB Pages: 10

K-Line Plus KDP-16

Brand: ABB Pages: 26

HPA 12kV

Brand: ABB Pages: 29

Mechanism HMB-8

Brand: ABB Pages: 34