The Zurn Medium Ratcheting

QickClamp crimp tool is factory set to

provide proper crimps. This should be

checked before use by making a test

crimp connection and checking it with

the QickClamp Go Gauge. As long as

the finished crimp connection gauges

properly, there is no need to adjust

the tool.

We recommend checking finished

crimp connections frequently with

the Zurn QickClamp Go Gauge.

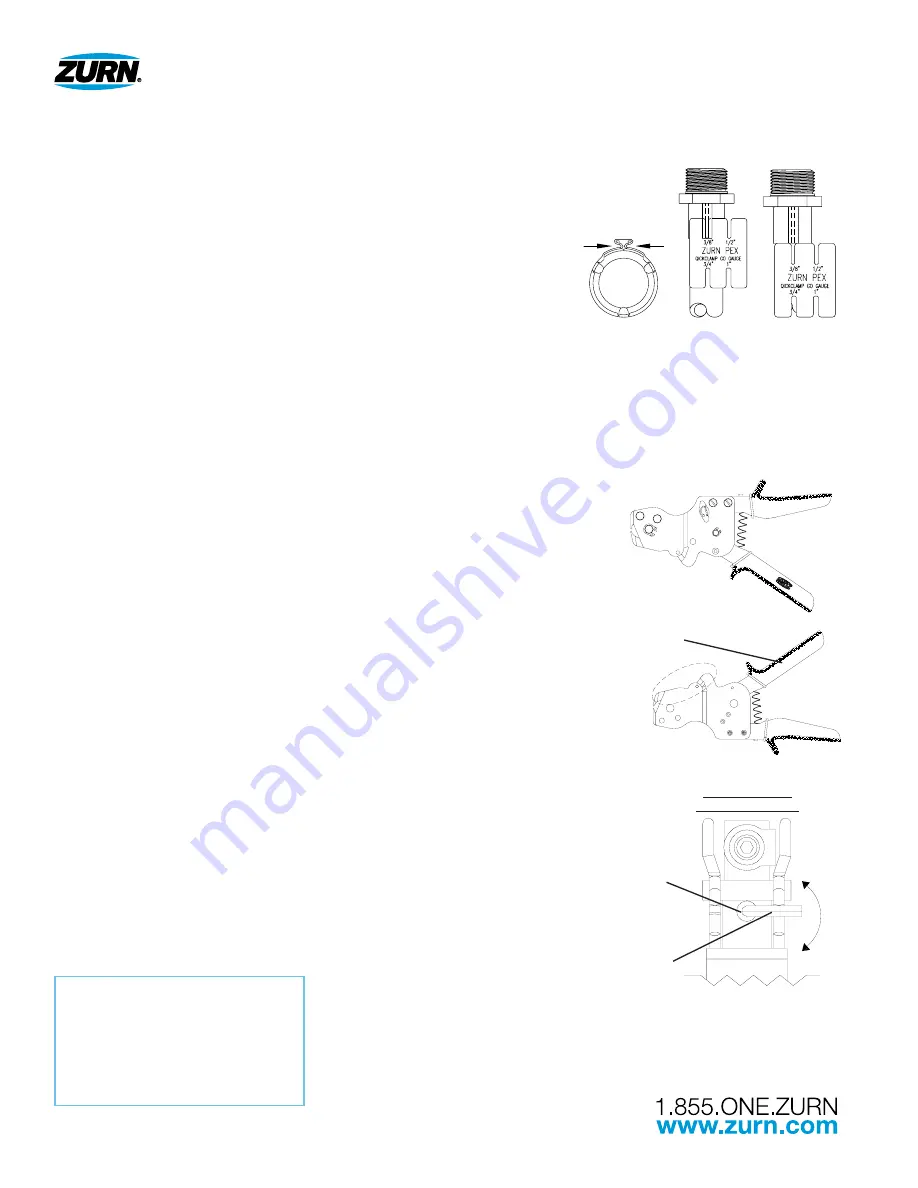

Using the QickClamp

Go Gauge

Check a completed connection with

the appropriate sized section of the

QickClamp Go Gauge. The gauge

should be applied to the half of the

QickClamp that is farthest away from

the fitting as shown in the ‘Gauging

Area’ illustration. If the QickClamp

does not go into the Go Gauge, the

fitting should be cut out, the tool

adjusted, and the fitting replaced. For

tool adjustment, see the instructions

supplied with the tool.

Adjusting the

Medium Ratcheting

QickClamp Tool

1. Close the jaws about half-way with

3 or 4 squeezes of the handles

(Figure 1).

2. Holding the tool with the jaws

pointed toward you and the moving

handle on top (Figure 2), find the

adjusting screw on the ratchet arm.

It is the lower screw that is visible

through a small hole.

3. Use the Allen wrench supplied with

the tool to raise or lower the screw.

4. Raising the screw by turning

counter-clockwise will cause the

jaw gap to increase at the point

the LED light comes on. It will

be rare that this adjustment will

be required.

5. Lowering the screw by turning

clockwise will cause the jaw gap to

decrease at the point the LED light

comes on. Do not turn the screw

more than ¼ turn at a time before

making a test crimp and checking

with the QickClamp Go Gauge.

Do not adjust more than required

to give finished clamps that

gauge properly.

OPERATING INSTRUCTIONS

Medium Ratcheting QickClamp

®

Tool

- QCRTQCRM

Form No. ZMKTG370-96, Rev. 04/16

ZURN PEX

®

,

INC.

116 Maple Street, Commerce, TX 75428 Phone: 855-ONE-ZURN (855-663-9876) • 1-800-209-2148

Gauging Area

Good Crimp

Adjust Tool and

Replace

Medium Ratcheting QickClamp

TM

Tool - QCRTQCRM

Operating Instructions

Check a completed connection with the appropriate

section of the QickClamp Go Gauge. Slide the appropriate

slot of the gauge onto the crimped pinch ear. If the

QickClamp pinch ear does not fit in the Go Gauge slot, the

fitting should be cut out, the tool adjusted and the fitting

replaced.

Using the QickClamp Go Gauge

Gauging Area

Good Crimp

Bad Crimp, Adjust

Tool & Replace Fitting

Adjusting Medium Ratcheting QickClamp Tool

Step 1: Close the jaws about half-way with 3 or 4 squeezes of the

handles (Figure 1).

Step 2: Holding the tool with the jaws pointed toward you and the

moving handle on top (Figure 2), find the Adjusting Screw

on the ratchet arm. It is the lower screw that is visible

through a small hole.

Adjusting Screw

Detail Side View of

Adjusting Screw Area

Moving Handle

The Zurn Medium Ratcheting QickClamp crimp tool is factory set to provide proper crimps. This should be checked before use by making a

test crimp

connection and checking it with the QickClamp Go Gauge. As long as the finished crimp connection gauges properly, there is no

need to adjust the tool.

We recommend checking finished crimp connections frequently with the Zurn QickClamp Go Gauge.

Form No. ZPFN185 Date: 6/11/09

C.N. No.120064

Rev.

ZURN PEX

®

PLUMBING AND RADIANT HEATING SYSTEMS

HWY 11 EAST, COMMERCE, TX, U.S.A. 75429 PHONE: 800/872-7277 FAX: 800/209-2148 WEBSITE: www.zurn.com

IN CANADA:

ZURN INDUSTRIES LIMITED

3544 NASHUA DRIVE, MISSISSAUGA, ONTARIO L4V 1L2 PHONE: 905/405-8272 FAX: 905/405-1292

Allen Wrench

Step 4: Raising the screw by turning counter-clockwise will

cause the jaw gap to increase at the point the LED light

comes on. It will be rare that this adjustment will be

required.

Step 5: Lowering the screw by turning clockwise will cause the

jaw gap to decrease at the point the LED light comes on.

Do not turn the screw more than ¼ turn at a time before

making a test crimp and checking with the QickClamp Go

Gauge. Do not adjust more than required to give finished

clamps that gauge properly.

Step 3: Use the allen wrench supplied with the tool to raise or

lower the screw.

Figure 1

Figure 2

Note: Using this tool for anything other than its

intended use will void the warranty.

For troubleshooting and repair assistance,

do not return tool directly to wholesaler.

Call Zurn Customer Care for assistance

at 1-855-ONE-ZURN.

See www.zurn.com for warranty information.