DOCK TRIALS

Page6-3

6-8 T

HROTTLE

P

AUSE

F

OLLOWING

S

ERVO

S

HIFT

A) Move the Station in command’s lever to the Ahead detent,

while monitoring the Shaft.

B) Start the stop-watch as soon as the Clutch Push-Pull cable stops

moving.

C) When the Shaft begins to rotate, stop the stop-watch.

D) Record the time expired on the stop-watch.

E) Program Function Code E5 as described in Section 5-5.2.6.1,

page 5-8

.

6-9 T

HROTTLE

P

AUSE

F

OLLOWING

S

OLENOID

S

HIFT

A) Move the Station in command’s lever to the Ahead detent, start

the stop-watch while monitoring the Shaft.

B) When the Shaft begins to rotate, stop the stop-watch.

C) Record the time expired on the stop-watch.

D) Program Function Code

E5

as described in Section 5-6.2.1.1,

page 5-10.

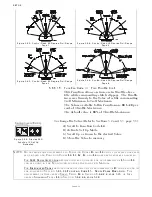

6-10 T

ROLLING

V

ALVE

6-10.1 Troll Servo Adjustments

A) Verify that the Troll Push-pull cable is positioned at the Full

Pressure (Lock-up) position.

B) If connected, disconnect the push-pull cable from the Trolling

Valve lever.

C) Secure the Troll lever using wire or rope so that the position

cannot change due to vibration or if accidentally bumped.

NOTE: A T

EST

C

ONTROL

H

EAD

AND

A

STOP

-

WATCH

ARE

RECOMMENDED

TO

DETERMINE

THE

CORRECT

SETTING

FOR

THE

T

HROTTLE

P

AUSE

. I

F

A

T

EST

C

ONTROL

H

EAD

IS

NOT

AVAILABLE

,

A

SECOND

PERSON

MAY

BE

NEEDED

.

NOTE: I

F

THE

TIME

RECORDED

IN

S

ECTION

6-8,

STEP

D)

EXCEEDS

5.0

SECONDS

,

A

C

LUTCH

P

RESSURE

I

NTERLOCK

IS

REQUIRED

. R

EFER

TO

S

ECTION

8-2,

PAGE

8-2.

NOTE: A T

EST

C

ONTROL

H

EAD

AND

A

STOP

-

WATCH

ARE

RECOMMENDED

TO

DETERMINE

THE

CORRECT

SETTING

FOR

THE

T

HROTTLE

P

AUSE

. I

F

A

T

EST

C

ONTROL

H

EAD

IS

NOT

AVAILABLE

,

A

SECOND

PERSON

MAY

BE

NEEDED

.

NOTE: I

F

THE

TIME

RECORDED

IN

S

ECTION

6-9,

STEP

D)

EXCEEDS

5.0

SECONDS

,

A

C

LUTCH

P

RESSURE

I

NTERLOCK

IS

REQUIRED

. R

EFER

TO

S

ECTION

8-2,

PAGE

8-2.

WARNING:

I

T

IS

PREFERABLE

TO

ADJUST

THE

T

ROLLING

V

ALVE

DURING

SEA

TRIALS

. H

OWEVER

,

IN

SOME

CASES

ADJUSTMENT

OF

T

ROLL

M

INIMUM

P

RESSURE

(L2)

CAN

BE

ACCOM

-

PLISHED

WHILE

AT

THE

DOCK

. D

O

N

OT

ATTEMPT

TO

MAKE

ANY

T

ROLL

ADJUST

-

MENTS

UNLESS

THE

DOCK

AND

THE

MOORING

LINES

ARE

CAPABLE

OF

SECURING

THE

VESSEL

WITH

FULL

THRUST

FROM

AT

LEAST

ONE

SCREW

.

Summary of Contents for ClearCommand 9000 Series

Page 132: ......

Page 133: ...APPENDIX A...

Page 134: ......

Page 139: ......

Page 140: ...Page A 4...

Page 143: ......

Page 144: ...10...

Page 148: ...Page A 18...

Page 149: ...Page A 19 TEMPLATE...

Page 150: ...Page A 20...

Page 152: ...Page A 22...

Page 154: ...Page A 24...

Page 156: ...Page A 26...

Page 157: ...Page A 27 Drawing 11488D 1 Twin Screw Single APS Connection Alternate Remote Switch...

Page 158: ...Page A 28...

Page 159: ...Page A 29 Drawing 11488D 2 Twin Screw Dual APS Connections...

Page 160: ...Page A 30...

Page 161: ...Page A 31 Drawing 11488D 3 APS Notes Page...

Page 162: ...Page A 32...

Page 164: ...Page A 34...

Page 166: ...Page A 36...

Page 170: ...Page A 40...

Page 172: ...Page A 42...

Page 176: ...Page A 46...

Page 178: ...Page C 48 ZF Mathers LLC 12125 Harbour Reach Drive Suite B Mukilteo WA 98275...

Page 179: ...APPENDIX B...

Page 180: ......

Page 234: ...Appendix B 6...

Page 238: ...Appendix B 10...

Page 242: ...Appendix B 14...

Page 247: ...Service Field Test Unit Reference Manual MM13927 Rev E 4 07...

Page 248: ......

Page 250: ...Page ii Table of Contents...

Page 264: ...SERVICE FIELD TEST UNIT MM13927 RvD 10 03 Page 3 2...

Page 265: ...APPENDIX C...

Page 266: ......

Page 267: ...Appendix C 1 Drawing 12284A 1 ClearCommand Diagram all options...

Page 268: ...Appendix C 2...

Page 269: ...Appendix C 3 Drawing 12284A 2 ClearCommand Circuit Board Connections...

Page 270: ...Appendix C 4...

Page 271: ...Appendix C 5 Drawing 12284A 3 ClearCommand Drawing Notes Page...

Page 272: ...Appendix C 6...