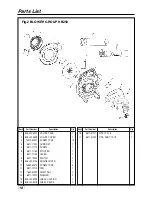

Parts List

NOTE :

1. Use KOMATSU ZENOAH genuine parts as specified in the parts list for repair and/or

replacement.

2. KOMATSU ZENOAH does not warrant the machines, which have been damaged by the

use of any parts other than those specified by the company.

3. When placing parts orders for repair and/or replacement, check if the model name and the

serial number are applicable to those specified in the parts list, then use parts number

described in the parts list.

4. The contents described in the parts list may change due to improvement.

5. The parts for the machine shall be supplied seven (7) years after the machine is

discontinued. [It is possible that some specific parts may be subject to change of their

delivery term and list price within the limit of seven (7) years after the machine is

discontinued. It is also possible that some parts may be available even after the limit of

seven (7) years.]

15

HANDHELD BLOWER

HB250

July 2004

DRIVE UNIT 40900101 and up ENGINE UNIT KU413473 and up

APPLICABLE SERIAL NUMBERS :