EN - 20

11. Inspecting and if necessary clean the heat

exchanger.

- Use a soft brush to clean the lamellae.

- Use a vacuum cleaner or air gun (no high

pressure) to remove dirt and dust.

Always clean against the direction of the

airflow. This prevent dirt from getting stuck in

the heat exchanger.

Only standard exchanger with a green cover and

Enthalpy exchanger with a blue cover:

a. Submerge the heat exchanger several times in hot

water (max. 40 °C).

b. Rinse the heat exchanger with clean hot tap water

(max. 40 °C).

c. Clasp the heat exchanger between both hands (on

the coloured side surfaces) and shake the water

from the heat exchanger.

Only an enthalpy exchanger with a bleu cover

can be washed with water. When having an

Enthalpy exchanger with a white cover do

never wash it with water.

Do not use aggressive cleaning agents or

solvents.

If the fans or preheater element filter also

need maintenance do not re-install the heat

exchanger yet.

12. If no more maintenance is necessary install all

parts in reverse order, reconnect the power and

carry out the self-test in accordance with menu

P76.

Fasten the screws to a maximum of 1.5

Nm. This is roughly equal to setting 2 of an

average battery-powered drill.

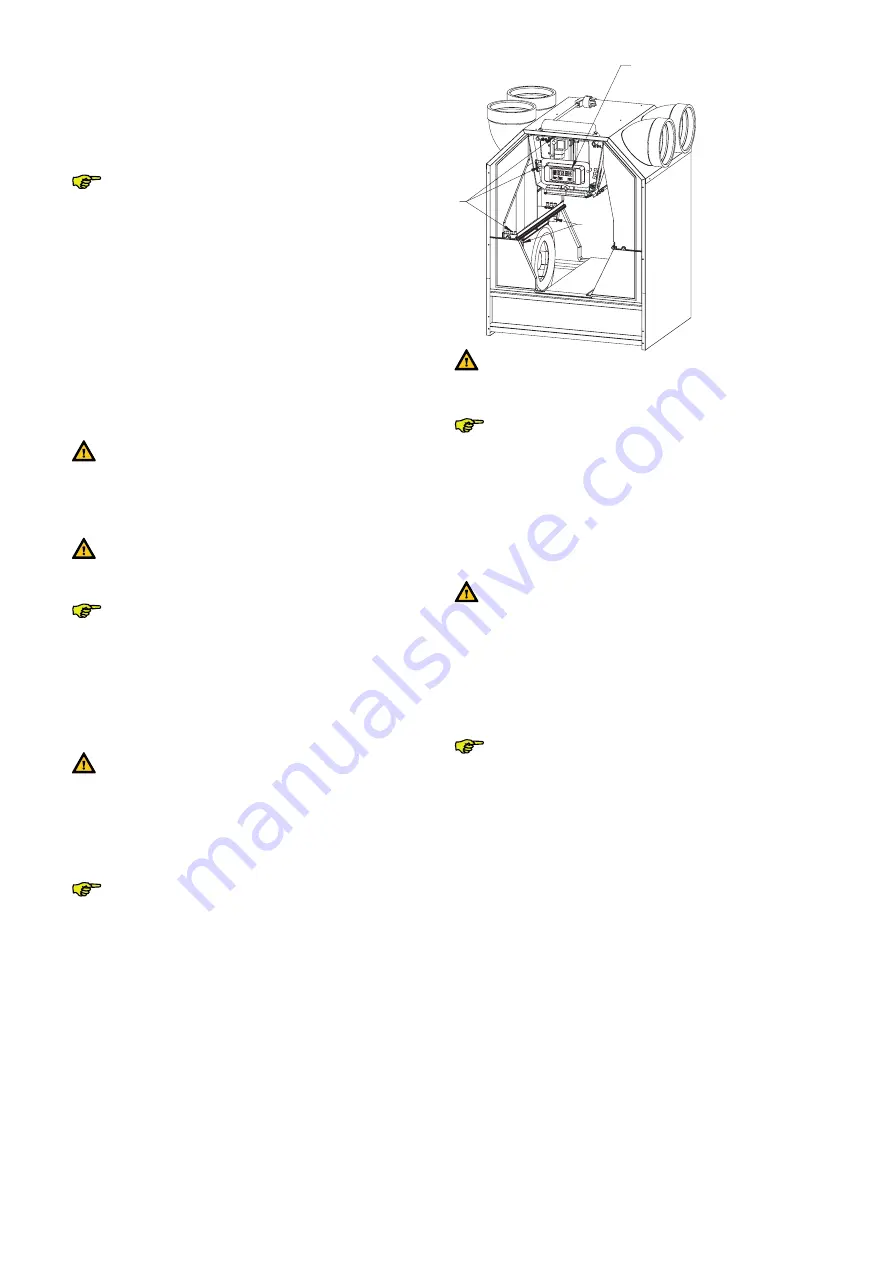

2.9.2 Inspecting and cleaning the fans

Check the fans once every 2 years.

1. Remove the heat exchanger as instructed in the

maintenance chapter of the heat exchanger.

2. Remove the small plastic panel (H) in front of the

control circuit board panel by unscrewing the two

screws.

3. Release the connectors (K) and the earth wire on the

control circuit board panel and fully remove the cables

including the two grommets (K).

4. Remove the entire scroll casing by pressing the

click fasteners (L).

5. Remove the inflow nozzle by pressing the click

fasteners surrounding the scroll casing.

6. Inspecting and if necessary clean the fans.

- Use a soft brush to clean the fan impellers.

- Use a vacuum cleaner to remove dust.

L

K

H

Do not damage the fan impellers or

temperature sensor.

If the preheater element filter also need

maintenance do not re-install the heat

exchanger yet.

7. If no more maintenance is necessary install all

parts in reverse order, reconnect the power and

carry out the self-test in accordance with menu

P76.

Fasten the screws to a maximum of 1.5 Nm.

This is roughly equal to setting 2 of an average

battery-powered drill.

2.9.3 Inspecting and cleaning the

preheater element filter

Clean the filter of the Preheater (if fitted)

once every 4 years.

1. Remove the heat exchanger as instructed in the

maintenance chapter of the heat exchanger.

2. Remove the small plastic panel (I) in front of the

control circuit board panel by unscrewing the two

screws.

3. Release the connectors (J) and the earth wire on

the control circuit board panel and fully remove

the cables including the two grommets (K).

4. Remove the cable (P) from the control circuit

board panel.

5. Remove the base (Q) of the Preheater element.

– The base is fitted in the electronic carriage with

four snap connections. Two snap connections

are located at the front (visible) and two at the

back (not visible).

6. Inspecting and if necessary clean the preheater

element filter.

- Clean the filter with a brush.

- Remove any deposit using a damp cloth.

7. Install all parts in reverse order.

8. Reconnect the power to the ComfoAir.

Summary of Contents for ComfoAir 350

Page 1: ...ComfoAir 350 Installer manual Cooling Fresh Air Clean Air Heating...

Page 4: ...EN 4...

Page 33: ...33 EN...

Page 34: ...EN 34...

Page 35: ...35 EN...