7

Important!

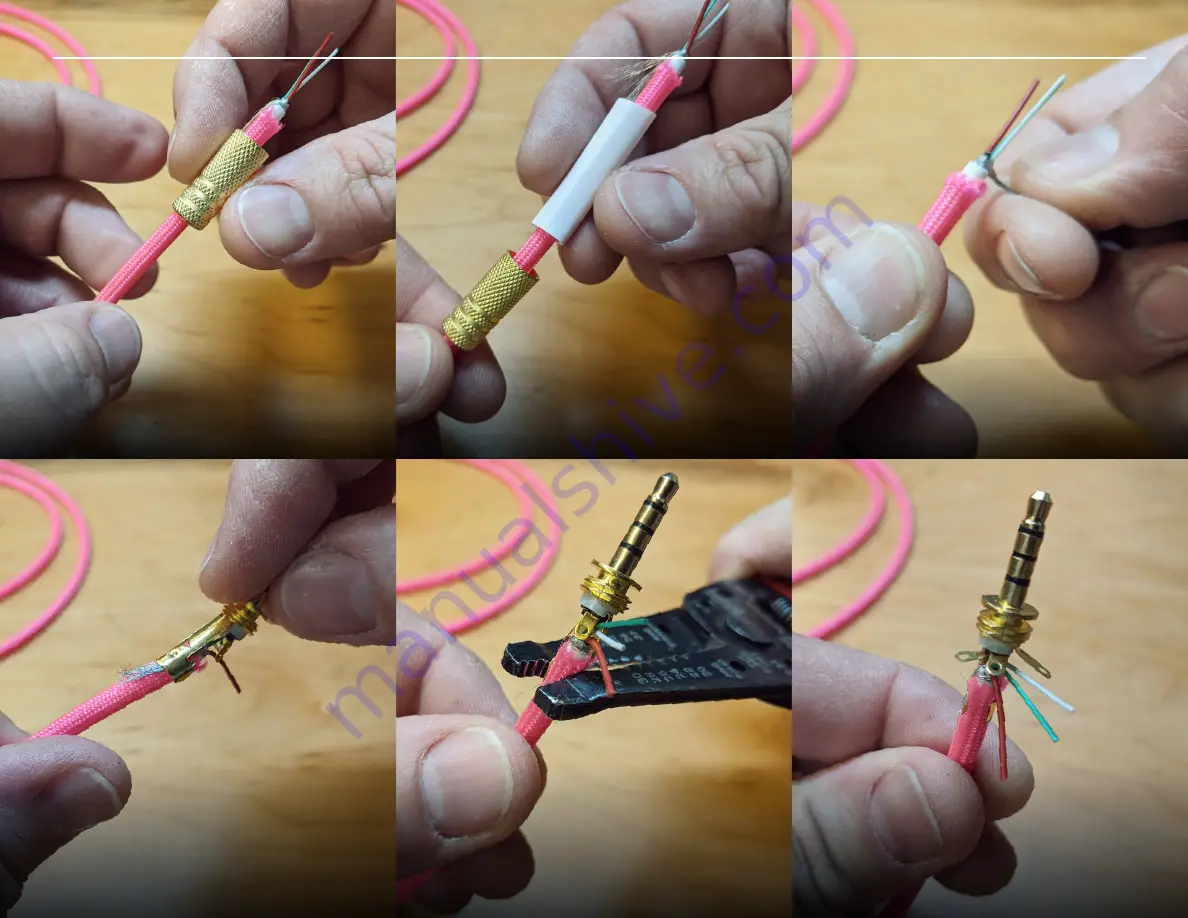

Before you start attaching the connector,

make sure you have slid the outer barrel onto the cable.

If you forget, you will need to re-do a lot of work later!

10

Place the connector onto the cable with the clamps

making solid contact with the gathered shielding. The

shielding needs to make physical contact with the clamp

tab for proper shielding/grounding.

8

Along with the barrel, remember to slide the heatshrink

onto the cable. You won't need the barrel and heatshrink

right away, so feel free to slide them further down the

cable and out of the way.

11

Using a pliers or wire stripper, crimp the clamps down

as securely as possible. Make sure the clamp is gripping

both cable and cord sleeving. Avoid crimping in only one

spot. Crimp, rotate a little, crimp again. You want the

clamps to hug the cable as much as possible.

9

Make sure the shielding is folded back, and gather/twist

it together on one side of the cable.

12

Inspect your work. Trim away any loose strands of

shielding. If they touch the other tabs/conductors later

it will cause a short. Gently fold the tabs up/out to make

inspection (and soldering) easier.

Note:

If you bend the tabs harshly, or too many times, they may

crack or break off.

Zap Cables Instructional Series

DIY TRRS Cable Kit Guide