Passwords (PASS ConF)

opps

Operator password (0 to 9999).

Tcps

Technician password (0 to 9999).

SAdr

Slave Address from 1 to 247

Communication Configuration (Comm Conf)

BAud

Baud Rate: 0- 1200

1- 2400

2- 4800

3- 9600

4- 19200

Prty

Parity

0- none

1- ODD

2-EVEN

StPb

Stop Bit

0- 1 stop bit

1- 2 stop bit

Manufacturer’s Calibration Page (PASS CAL) - Factory Set

Explanations

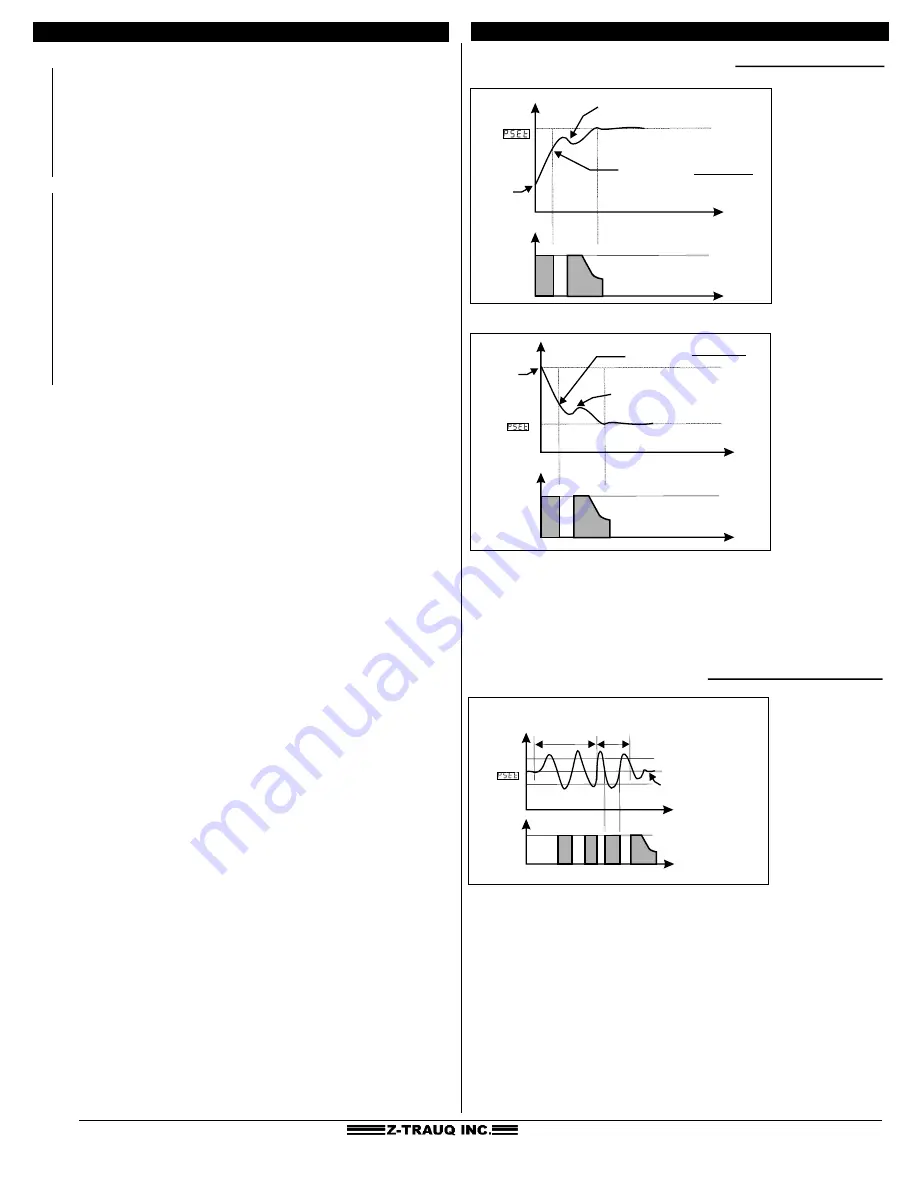

Firstly, the control form must be PID in order for this tuning method to operate.

PID coefficients

save to

memory.

parameter is

changed

t

PID coefficients

save to

memory.

parameter is changed

t

If the tunn parameter is

Stun or At.St, step response

tuning is selected. When

t h e d e v i c e i s f i r s t

energized, the actual value

is compared to the set

value. If the set value is

greater than the actual

value, the process output is

enegized until the

start value+((set value)/2)

is reached. The process

output is reduced to 0% and

the device ensures that the

temperature has begun to

fall. The

are calculated and

d

If the tuning is

completed successfully,

the tunn

from Stun to NO or At.St o Atun depending on the original choice.

If the set value is less than

the actual value and the

cooling PID is selected, the

process output is energized

until the

start

value-((set

value)/2)

is reached

.

The process

output is reduced to 0% and

the device ensures that the

temperature has begun to

rise. The

are calculated and

d

If the tuning is

completed successfully, the

tunn

from Stun to NO or At.St o

Atun depending on the

original choice.

During tuning, the set value

can not be changed. Step

response is canceled without changing the PID set values when any of the following conditions

applies: the heating PID is canceled during Heating step response; when the cooling PID is canceled

during Cooling step response; when there is a sensor break error or when the step response tuning

operation can not be completed within 8 hours (the AT LED flashes. The error can be cleared with the

“SET” button). If the power to the device is removed and reapplied, the device carries out step

response tuning again.

Firstly, the control form must be PID in order for this tuning method to operate.

The user can decide at any

time to use this tuning

method by selecting Atun

or At.St for the tunn

parameter in the run list.

After changing the set

value, if the difference

between the newly defined

and former set values is

g r e a t e r t h a n t h e

proportional band

+/-(scale x P-Ht)/1000

if

heating or heating/cooling

or

+/-(scale x P-CL)/1000

if cooling, the contoller

will automatically start this

function.

In the event that the actual value moves outside the set value by

+/-Strn

3 times while the device is

executing the PID control, the Attn parameter becomes YES and tuning is started.

If the Attn parameter is YES, the device begins tuning from the point where it stands at that moment. If

the heating and cooling PIDs are selected together, or if only the heating PID is selected, Heating Limit

Cycle is performed; if only the cooling PID is selected Cooling Limit Cycle is carried out. If the Limit

Cycle operation can not be completed within 8 hours, tuning is cancelled and the Attn parameter

becomes NO. The PID parameters remain as they were before this failed session.

If Heating Limit Cycle is being done, tuning is performed according to

set-((set temperature)/4),

if

cooling Limit Cycle is being done, tuning is performed according to

set+((set temperature)/4)

.

At the end of tuning the Attn parameter becomes NO and the PID parameters are saved to memory.

If a sensor break error occurs, the tuning operation is paused until the sensor connection is re-

established. When the sensor connection returns to normal, the tuning operation is recommenced. If

the Limit Cycle tuning operation can not be completed within 8 hours the tuning operation is cancelled

(the AT LED flashes. The error can be cleared with the “SET” button).

While the tuning operation is under way, the Process Set Value (PSEt) can not be changed.

P.5

1-877-798-7287

Process

Value

Time

During

Atun

operation

100%

Process

Output

Control is

unstable

PID coefficients are

determined and system

becomes stable.

Process Set

Value ( )

Time

LIMIT CYCLE TUNING (Auto Tune)

Process

Value

Time

100%

Process

Output

Stun

Start

Value

PID coefficients are determined

and system becomes stable.

Start Value + [ ( Set Value) ]

2

Process Set

Value ( )

Time

STEP RESPONSE TUNING (Self Tune)

Process

Value

Time

100%

Process

Output

Stun

Start

Value

Process Set

Value ( )

Start Value - [ ( Set Value) ]

2

PID coefficients are determined

and system becomes stable.

Time

ESM 7750 v10R7

SU-L

SV min. limit. Adjustable from min. scale to

SU

-u

value . It’s the minimum value of

the operation scale.

out3

Output configuration (

heat

,

cool

,

Lout

)

Con3

Control type (ON/OFF or PID)

HYS3

Hysteresis value 0% to 50% of FS (expressed in degrees)

tm3

Minimum OFF time (0.0 to 100.0 seconds). Active in on.off control

Lou3

0=Alarm output

1=Manual / Automatic data output

2=Sensor break alarm

3=Output active when PV is outside operating range

4=Output activates at end of R/S 5=Analog input module sensor break alarm

6=PV of second input is <LoL1 / 2 or >uPL1 / 2

aLt3

Alarm type:

0-Process high alarm

1-Process low alarm

2-Deviation high alarm

3-Deviation low alarm

4-Deviation band alarm

5-Deviation range alarm

6=Heater failure alarm (CT input module must be installed)

NOTE: 2,3,4,5,are not available if Lou3

…

0.

aLH3

Alarm hysteresis. Active if output 3 is alarm output. If ALS3=0 or there is no second

sensor input, adjustment is 0 - 50% of process input scale (uPL-LoL).

If ALS3=1and an analogue input is present, then it can be adjusted from 0 to 50% of

the input module’s scale.

If a CT input module is installed and ALt3=0006, adjust from 0.0 to 20.0A.

SU-u

SV max. limit. Adjustable from

SU-L

value to max. scale. It’s the maximum

value of the operation scale.

HYn3

Mode of Hysteresis

0=SV+(HYS/2) and SV-(HYS/2)

1=SV and SV+HYS or SV and SV-HYS

Output - 3

If Module 1 or 2 is EMI-410, EMI-430, EMI-440 or EMI-450 (continued)

RTS1 / 2

Selection of sensor type and scale (see Table 1)

UNT1 / 2

°C=Centigrade

°F=Fahrenheit

LoL1 / 2

Minimum value of second sensor input range

uPL1 / 2

Maximum value of second sensor input range

IPu1 / 2

Module 1 / 2 PV offset ±10% of FS1. Added to the input reading in degrees

iFL1 / 2

Module 1 / 2 Input signal filtering time. (From 0,0 to 900,0 secs)

rES1 / 2

Determines whether the measured value is the result of the input on

terminals 1,2, 3 or from the input module. Visible only when decimal point

and unit parameters are the same for both inputs. If YES, then analogue

input module

’

s value is used as the Set Value. If NO, then SV=PSET

Parameters

UAS1 / 2

Selection of sensor type and scale. (See Table1)

DPN1 / 2

Analogue input module decimal point position

0 = 9999

1 = 999.9

2 = 99.99

3 = 9.999

ICA1 / 2

Analogue input module calibration

type

0 = None

1 = Dual point

ICL1 / 2

Minimum value for dual point calibration

ICH1 / 2

Maximum value for dual point calibration

uNT1 / 2

°C=Centigrade

°F=Fahrenheit

U=Other units

LoL1 / 2

Minimum value of second sensor input range

uPL1 / 2

Maximum value of second sensor input range

Ipu1 / 2

Module 1 / 2 PV offset ±10% of FS1. Added to the input reading.

iFL1 / 2

Module 1 / 2 Input signal filtering time. (From 0

.

0 to 900

.

0 secs)

rES1 / 2

Determines whether the measured value is the result of the input on

terminals 1,2, 3 or from the input module. Visible only when decimal point

and unit parameters are the same for both inputs. If YES, then analogue

input module

’

s value is used as the Set Value. If NO, then SV=PSET

I

SL1 or

I

L2=

1

f

I

S

If

I

L

L2=

S

1=

or

IS

2

General Configuration (Genn ConF)

Su-L2

Second sensor SV min. limit. Adjustable from min. scale to

SU

-u

2

value .

It’s the minimum value of the operation scale.

SU-u2

Second sensor SV max. limit. Adjustable from

SU-L

2

value to max. scale.

It’s the maximum value of the operation scale.

ALS3

Alarm sensor selection. If output 3 is an alarm output and an analogue module is

installed:

0 = Alarm in accordance with input sensor (on terminals 1,2,3)

1 = Alarm in accordance with analogue input module (1 or 2)

Alarm delay from fault 0.0 to 9999 seconds

Aon3

Alarm reset from fault 0.0 to 9998 seconds.

For high limit with manual reset only, select 9999. Display will read LtCH to indicate

latch feature has been selected.

AoF3

ULtt

Motorized valve travel time can be adjusted from 5 to 600 sec.

ULHY

Min. activation time of motorized valve and is adjustable from 0.1 to 5.0%.

eg. If ULtt=100s and ULHY=1.0% then the minimum activation time is (100s*1%) or

1 second.

Summary of Contents for ESM 7750

Page 2: ...17 18 output 3...