2

TECHNICAL SPECIFICATION

●

Input type :

K, S, R, E, J, N, Pt100

●

Measurement range :

K(0

~

1300

℃

), S(0

~

1700

℃

), R(0

~

1650

℃

), E(0

~

800

℃

), J(0

~

1000

℃

), N(0

~

1300

℃

), Pt100(-200

~

600

℃

)

●

Measurement accuracy :

0.3%FS

±

1

℃

●

Temperature display resolution :

1

℃

●

Control mode :

On-off control mode or Artificial Intelligence control with auto tuning.

●

Output mode (modularized) :

L1, G, W1, K1, K3 modules are selectable

●

Alarm function :

High limit and deviation high alarm.

●

Power supply voltage rating :

100-240VAC, -15%, +10% ; 50-60Hz.

●

Power consumption :

≤

3W.

●

Ambient :

Temperature of

-10

~

60

℃

, humidity of 0

~

90RH%

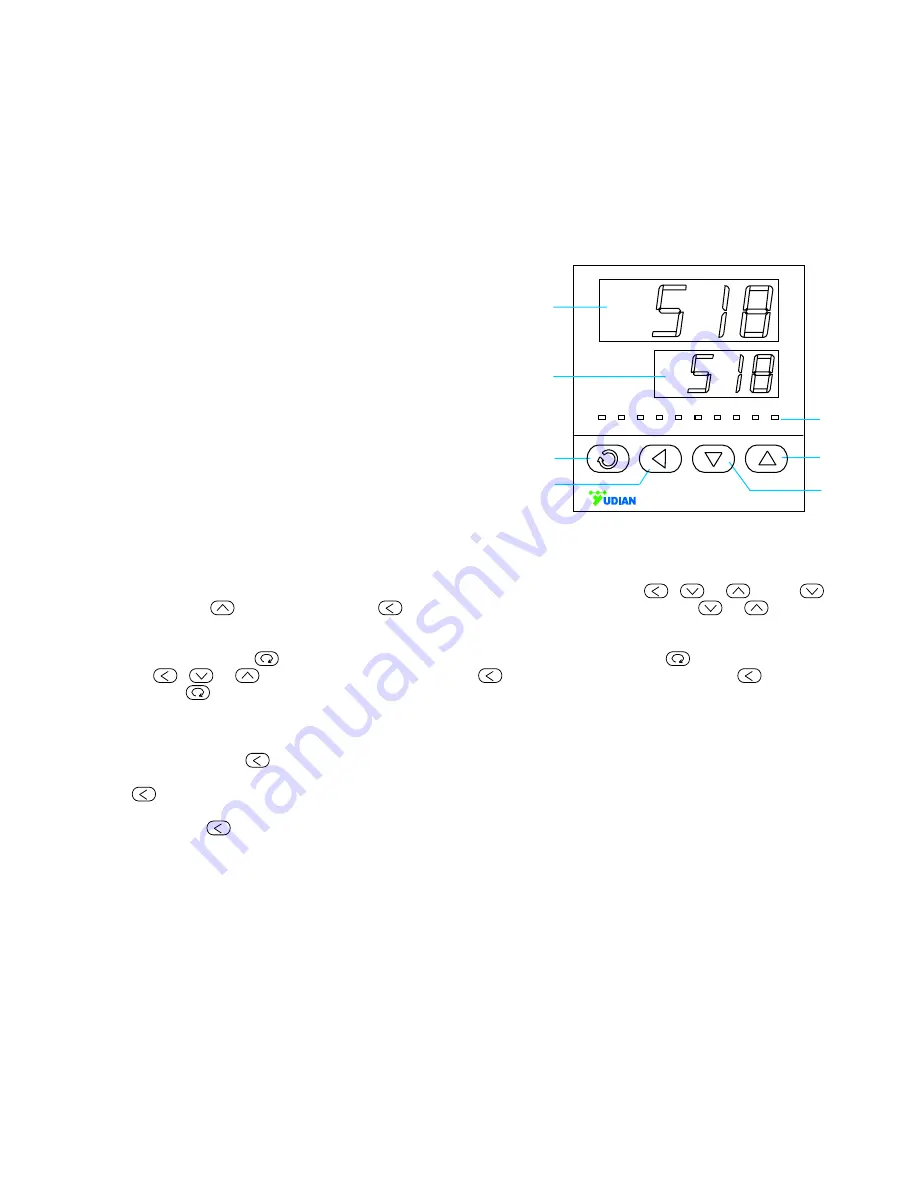

FRONT PANEL AND OPERATION

①

Upper display window, displays PV, or code of a parameter

②

Lower display window, displays SV, alarming code, or value of a parameter

③

Setup key, for accessing parameter table, and confirming change.

④

Data shift key, also for activating auto turning

⑤

Data decrease key

⑥

Date increase key

⑦

Indicator lamps (MIO, OP1, OP2, AL1, AL2, AU1and AU2 indicate the I/O actions

of the corresponding modules. MAN and PRG are non-applicable for AI-508.)

Basal display status :

When power on, the upper display window of the instrument

shows the process value (PV), and the lower window shows the setpoint (SV). This

status is called basal display status. When the input signal is out of the measurable

range (for example, the thermocouple or RTD circuit is break, or input specification sets

wrong), the upper display window will alternately display “orAL” and the high limit or the

low limit of PV, and the instrument will automatically stop output.

OPERATION DESCRIPTION

●

Set Value Setting:

In basal display status, if the parameter lock “Loc” isn't locked, we can set setpoint (SV) by pressing

、

or

. Press

to

decrease the value,

to increase the value, and

to move to the digit expected to modify. Keep pressing

or

, the speed of

decreasing or inscreasing value gets quick. The maximum value of the setpoint is HIAL.

●

Parameter Setting:

In basal display status, press

and hold for about 2 seconds can access Field Parameter Table. Pressing

can go to the next parameter;

pressing

、

or

can modify a parameter. Press and hold

can return to the preceding parameter. Press

(don't release)

and then press

simultaneously can escape from the parameter table. The instrument will escape auomatically from the parameter table if no

key is pressed within 30 seconds.

●

Artificial Intelligence control and auto tuning

When AI control method is chosen, the control parameters can be obtained by running auto-tuning. At the first time of running auto-tuning, in

basic display status, press

for 2 seconds, “At” will flash at lower display window and the instrument executes on-off control. After 2 to 3

cycles of on-off action, the instrument will obtain the values of PID control parameters. If you want to escape from auto tuning status, press and

hold

for about 2 seconds until the "At" flash stops. Depending on the system, the time of auto tuning can be several seconds to several

hours. After the auto tuning finishes, the parameter “Ctrl” automatically changes to 3 (the initial value is 1) or 4, and then user can’t active auto

tuning by pressing

for 2 seconds. If user wants to run auto tuning again, setting parameter “CtrL” to 2. (Refer to the description of

parameter “CtrL”)

Note 1:

Before running auto-tuning, setpoint should be set to an often-used value or middle value first, and then start auto-tuning. Generally, for

application with 10%

~

80% time on heating can obtain satisfying auto-tuning result. If the heating time is not in the range of 10

~

80%, the

auto-tuning will run for a long time and can’t get satisfying result. Raising setpoint for heating time less than 10% or decreasing setpoint for

heating time greater than 80% can improve auto-tuning result.

Note 2:

Don’t modify the setpoint during auto-tuning. It may affect the precision of auto-tuning.

Note 3:

The temperature fluctuation caused by interference may affect the precision of auto-tuning. Besides checking the wiring, increasing the

parameter dL (input digital filter) can also reduce interference.

Note 4:

After auto-tuning finishes, generally, the temperature rising has a little over-shoot (about 1

~

3

℃

). It is because considering that the

transducer is often placed between the heater and heated material, and a little over-shoot can shorten the time of rising to setpoint and save

power. (Generally, the temperature of transducer can be raised quick than that of heated material)

A/M

RUN/HOLD

AI

STOP

①

②

③

④

⑤

⑥

⑦

PV

SV

AI