SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

FORM 155.32-ICOM2.EN.UL

ISSUE DATE:1/10/2018

36

JOHNSON CONTROLS

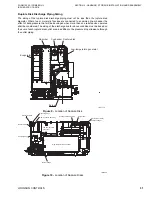

HOT INSULATION/COLD INSULATION PROCEDURE

1. The recommended materials and their thickness for hot insulation/cold insulation are

shown in

2. Use a bonding agent, iron wire, iron band, or other tool used to fix the hot insulation/

cold insulation materials. Never rivet them. The use of welding pins is not recom-

mended.

3. Make the outer covering, flanged parts, and evaporator water chamber casing easily

removable to facilitate servicing.

4. The points that require hot insulation/cold insulation. See

.

5. The casing of the absorber/condenser water chamber does not require hot insulation/

cold insulation. If insulation is used, make it easily removable.

6. For the high temperature generator, install the insulation in a way to permit removing

the front, sides, and rear separately. In addition, make a removable part around the

rear end for inspection of the temperature relay and sensor.

Table 3 -

Insulating Material and Thickness

Table 4 -

Points Requiring Hot/Cold Insulation

Figure 15 -

Hot and Cold Insulation Details

HOT INSULATION

COLD INSULATION

Material

Rock wool or glass wool

Polyurethane foam, polystyrene foam, or glass wool

Thickness

2 inches

2 inches

POINT REQUIRING

HOT INSULATION

POINT REQUIRING

COLD INSULATION

POINT THAT MUST NOT

BE HEAT-INSULATED

High Temperature

Generator

Evaporator Shell

Sight Glass

Exhaust Gas Duct

Evaporator Water Chamber Case

Valve Manipulator

Heat Exchanger

Refrigerant Spray Piping

Pressure Gauge

Low Temperature

Generator

Refrigerant Blow Piping

Thermometer Insertion

Hole

Point Carrying “Hot

Insulation” Label

• Point Carrying “Cold Insulation” Label

• Valve for vacuuming (factory use only)

Relay Insertion Hole

LDxxxxx

LD26843

.UZOTY[RGZOUT

)URJOTY[RGZOUT

.=.KGZ+^INGTMKX

.=.KGZ+^INGTMKX

.=.KGZ+^INGTMKX