JOHNSON CONTROLS

32

FORM 160.76-O1

ISSUE DATE: 05/22/2019

SECTION 7 - PREVENTIVE MAINTENANCE

MOTOR RE-LUBRICATION INSTRUCTION

General

Johnson Controls supplied electric drive motors have

maintenance requirements for re-lubrication (greasing)

of the drive end (DE) and non-drive end (NDE) ball

bearings.

In recent years the type of grease to be utilized is typi-

cally identified on the motor data plate. Below, in

, we have provided a quick guide. How-

ever, always perform a verification with the motor data

plate - any differences between the quick guide and the

motor data plate must be communicated to the product

technical support (PTS) team prior to completing the

greasing application.

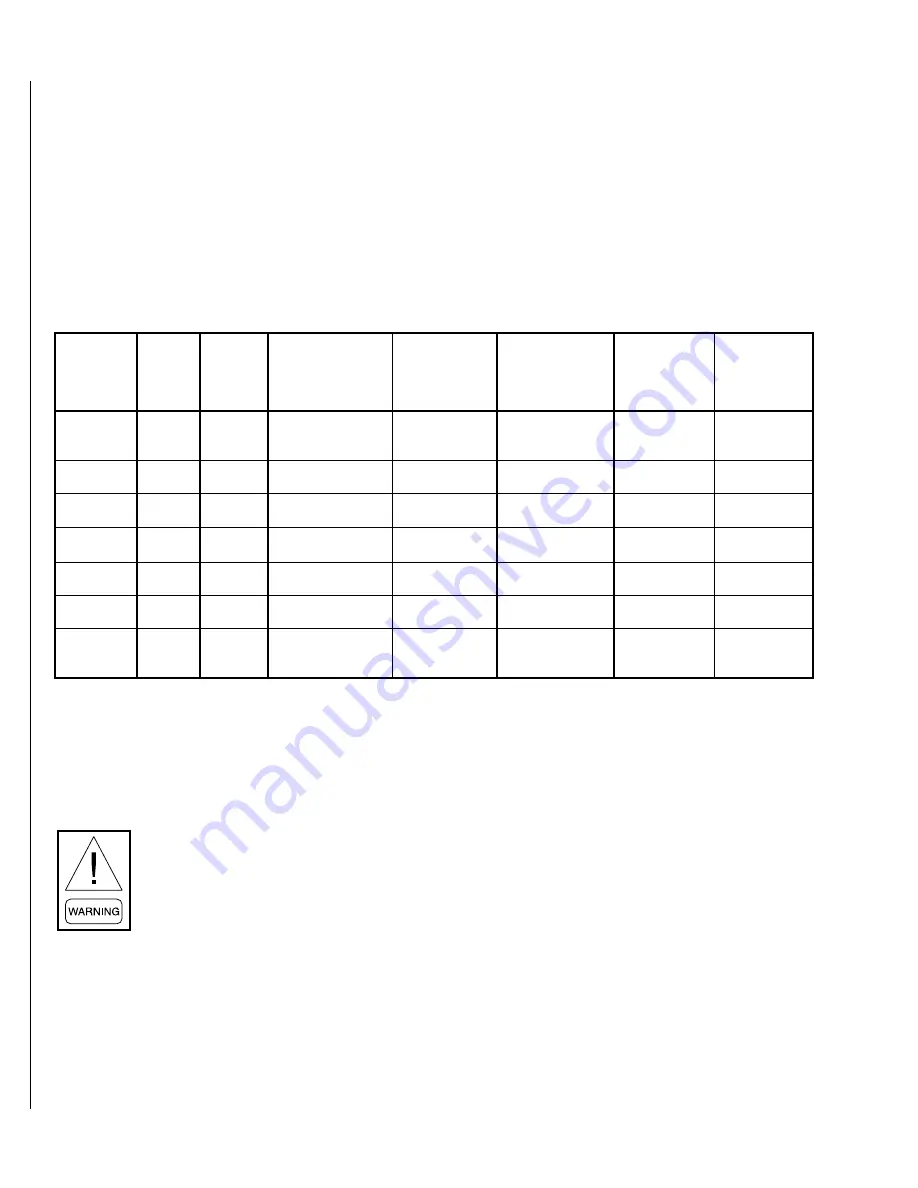

ANTI-

FRICTION/

BALL

BEARING

MOTOR

HOURS

TO

LUBE

MAX

SHAFT

IDLE

TIME

FRAME

PREFERRED

GREASE*

ALTERNATIVE

GREASE*

GREASE

QUANTITY

GREASE

METHOD

PREFERRED**

***ALTERNATE

GREASE

METHOD

WEG

2200

90 Days

Mobil Polyrex EM

N/A

See Manufacturer's

nameplate for ap-

plicable quantity

Operational > 5

mins

Operational

Toshiba

1000

90 Days

Mobil Polyrex EM

N/A

1.5 cubic inches

At rest

Operational

Teco

1000

90 Days

Mobil Polyrex EM

Chevron SRI-2

1.5 cubic inches

At rest

N/A

ABB

Per data

plate

90 Days

Kluberplex BEM41-

132

Mobilith SCH100

1.5 cubic inches

Operational

At rest

Ram

1000

90 Days

Mobil Polyrex EM

Chevron SRI-2

1.5 cubic inches

At rest

Operational

Reliance

1000

90 Days

Shell Alvania RL3

Mobilith SHC100

1.5 cubic inches

At rest

Operational

Siemens

1000

90 Days

See manufacturer's

nameplate for ap-

plicable grease

N/A

See manufacturer's

nameplate for ap-

plicable grease

At rest

N/A

TABLE 3 -

QUICK GUIDE TO MOTOR GREASING AND SHAFT ROTATION INTERVALS

* Never mix grease type or brand. If changing from or to the alternate or preferred, the bearing cavities, housings, and lines must be cleaned

of the old grease.

** Follow all standard lookout tag out procedures prior to greasing motor.

** After greasing motor at rest, run motor for a minimum of 45 minutes before replacing plug if equipped.

*** Motor must be equipped with grease extensions on DE bearing for performance of this task.

Verify with motor nameplate any discrepancy before lubricating - contact technical support for additional information/clarification.

Remove grease plug, if equipped, prior to greasing. Not every grease interval will result in used grease discharge.

Work on this equipment should only be done by properly trained personnel who are qualified to

work on this type of equipment. Failure to comply with this requirement could expose the worker,

the equipment, and the building and its inhabitants to the risk of injury or property damage.

The instructions in this document are written assuming the individual who will perform this work

is a fully trained HVAC and R journeyman or equivalent, certified in refrigerant handling and

recovery techniques, and knowledgeable with regard to electrical lock out/tag out procedures. The

individual performing this work must be aware of and comply with all Johnson Controls, national,

state, and local safety and environmental regulations while carrying out this work. Before attempt-

ing to work on any equipment, the individual should be thoroughly familiar with the equipment

by reading and understanding the associated service literature applicable to the equipment. If

you do not have this literature, you may obtain it by contacting a Johnson Controls service office.

Should there by any question concerning any aspect of the tasks outlined in this bulleti, please consult

a Johnson Controls service office prior to attempting the work. Please be aware that this information

may be time sensitive and that Johnson Controls reserves the right to revise at any time. Be certain

you are working with the latest information.