panels. Intake pressure drop will be read on one side of the

UERV, exhaust on the other side. Refer to blower

performance Tables showing specific air volumes at

various speeds. The table is for balanced air flows (fresh

air and exhaust air are equal), unbalanced airflow will

effect UERV performance.

1- Disconnect main power to unit before making

adjustment to economizer and/or UERV unit.

2- Replace UERV control access cover.

3- Set thermostat to normal operating position.

4- Restore power to unit.

X -

Maintenance

1- All motors use prelubricated sealed bearings; no further

lubrication is necessary.

2-Make visual inspection of dampers, linkage assemblies

and UERV rotating bearings during routine

maintenance. Filters should be checked periodically

and cleaned when necessary. Filter is located in fresh

air hoods.

DO NOT

replace permanent filters with

throwaway type filters.

3-Annual inspection of the self cleaning wheel is

recommended. With power disconnected, remove

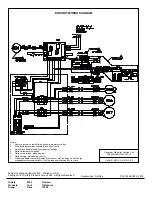

UERV access panels (rear) and unplug [J150 & P150]

(Refer to wiring diagram in this instruction manual).

Remove media and wash with water and/or mild

detergent. Replace media by reversing the above

procedure.

4-To install wheel segments follow steps A through E .

See

Figure 16. Reverse procedure for segment

removal.

A- Unlock two segment retainers (one on each side of the

selected segment opening.

B- With the embedded stiffener facing the motor side,

insert the nose of the segment between the hub plates.

C- Holding segment by the two outer corners, press the

segment towards the center of the wheel and inwards

against the spoke flanges. If hand pressure does not

fully seat the segment, insert the flat tip of a screw driver

between the wheel rim and outer corners of the

segment and apply downward force while guiding the

segment into place.

D- Close and latch each segment retainer under segment

retaining catch.

E- Slowly rotate the wheel 180

o

. Install the second

segment opposite the first for counterbalance. Rotate

the two installed segment 90

o

to balance the wheel

while the third segment is installed. Rotate the wheel

180

o

again to install the fourth segment. Repeat this

sequence with the remaining four segments.

PAGE 6

MAXA-MI$ER™

UNITARY ENERGY RECOVERY VENTILATOR

MODEL VR036A15H/25H & VR046A15H/25H

& VR062A15M/H/25M/H (STATIONARY)

INSTALLATION

INSTRUCTIONS

B

C

A

D

E

D

HUB

SEGMENT

FIGURE 16

SPOKE

SEGMENT RETAINER CATCH

WHEEL RIM

SEGMENT RETAINER

Figure 14

Figure 15

DELTA PRESSURE

(EXHAUST AIR)

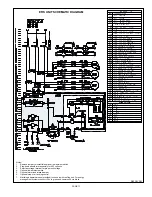

FUSE BLOCK

Summary of Contents for MAXA-MISER VR036A15H

Page 10: ...PAGE 10 ...