CAUTION: If the valve stem is backed out beyond the retaining

ring, system pressure could force the stem out of

the valve body and possibly cause personal injury.

In the event that the retaining ring is missing do not

attempt to open the valve.

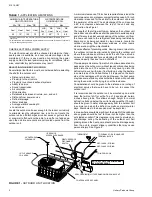

Some units may have factory installed 1-1/8" ball valves. To

open the valve, remove the brass valve stem cap, located on

the side of the valve, with an adjustable wrench. Next, turn the

valve stem 1/4 turn CCW (away from unit).

All caps must be replaced to prevent leaks.

Replace valve cap finger tight, then tighten an additional

1

⁄

6

of

a turn with a wrench, using a back-up wrench on the valve body.

WARNING:Do not under any circumstance connect refrigera-

tion gauges or refrigerant cylinders to the vapor line

service valve (large) gauge port. Personal injury

could result if the system is operating in the heating

mode. When checking pressures use the gauge

port located on the liquid service valve and the

gauge port located to the right of the vapor line

service valve.

OIL TRAPPING

When the outdoor unit is above the indoor coil oil trapping is

necessary. Please refer to APPLICATION DATA, 690.01-AD1V

(1296) and worksheet 690.01-AD1.1V (791) "General Piping

Recommendations and Refrigerant Line Length".

Check the system for correct charge after all components of

the system have been installed, connected and wired correctly.

Connect service gauges to suction and discharge service ports.

WARNING:Do not under any circumstance connect refrigera-

tion gauges or refrigerant cylinders to the vapor line

service value (large) gauge port. Personal injury

could result if the system is operating.

Allow unit to operate until system pressures and temperatures

have stabilized, making sure that the pressure and tempera-

tures align with unit service data. If not, check system charge

and adjust if necessary.

ELECTRICAL WIRING

WARNING:To prevent electrical shock, open remote discon-

nect so electrical supply to outdoor unit is shut off.

Contactor does not open both sides of the 208/230

or 460 volt electrical circuit.

POWER SUPPLY

All wiring must comply with N.E.C. and local codes. See rating

plate and product data sheet for volts, frequency, phase, maxi-

mum fuse size and minimum branch circuit ampacity. Refer to

the wiring diagram inside the unit control box cover before

connecting to power supply.

1. The line voltage service wiring for the outdoor unit must

include a disconnect switch located within sight of the

outdoor unit.

2. Use the correct size fuse or circuit breaker as listed on the

unit rating plate and data sheet. See Tabular Data Sheet for

minimum recommended wire size. If using nonmetallic-

sheathed cable (NM or NM-B) ampacities shall be that of

60°C conductors per NEC 336-26.

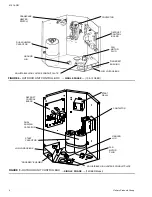

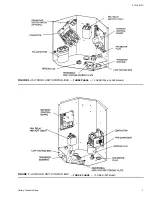

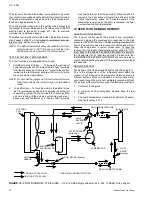

3. Wiring connections. —Two are provided in the control box:

a. One for low voltage wiring.

b. One entrance for high voltage Ll and L2

The adjustable High Voltage Conduit Plate is factory

installed for 1/2" conduit connections. For 3/4" conduit,

remove the screw holding the plate in place and reverse

the location of the holes. For 1" conduit, remove the

conduit plate and discard. Re - install screw to maintain

the integrity of the unit structure, regardless of the

conduit being used. See Figures 4, 5, 6 and 7.

4. Power connection to the unit is facilitated by screw termi-

nals, marked Ll and L2 on the outdoor unit contactor. See

Figures 4, 5, 6 and 7.

5. Ground the outdoor unit using the ground lug provided.

Unless the outdoor unit is grounded through proper wiring

to the service entrance ground, a suitable separate ground

should be provided at the outdoor unit.

CAUTION: Casing or cabinet must be permanently grounded

in accordance with National Electric Code or other

applicable local codes.

LOW VOLTAGE

Pig-tail connector wires are provided from the defrost control

board to the low voltage section of the control box. A "fingered"

bushing is provided in the low voltage knockout hole. If 1/2"

conduit is used for the low voltage wiring, the bushing is to be

removed.

1. Route the low voltage cable through the fingered bushing

in the low voltage junction box. See Figures 4, 5, 6 and 7.

2. Using wire nuts, connect the low voltage wiring within the

low voltage box.

3. A minimum of 19 AWG wire must be used in connecting the

low voltage control wiring between the outdoor unit, air

handler and thermostat.

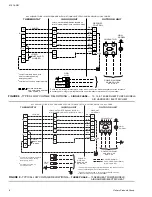

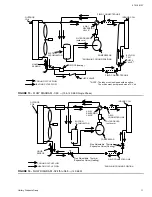

Connect thermostat and control package wiring as shown in

Figure 8 (Single Phase), Figure 9 (Three Phase) and per the

instructions packed with those pieces.

515.16-N3Y

Unitary Products Group

5