IM 05P01F31-11EN page 8/10

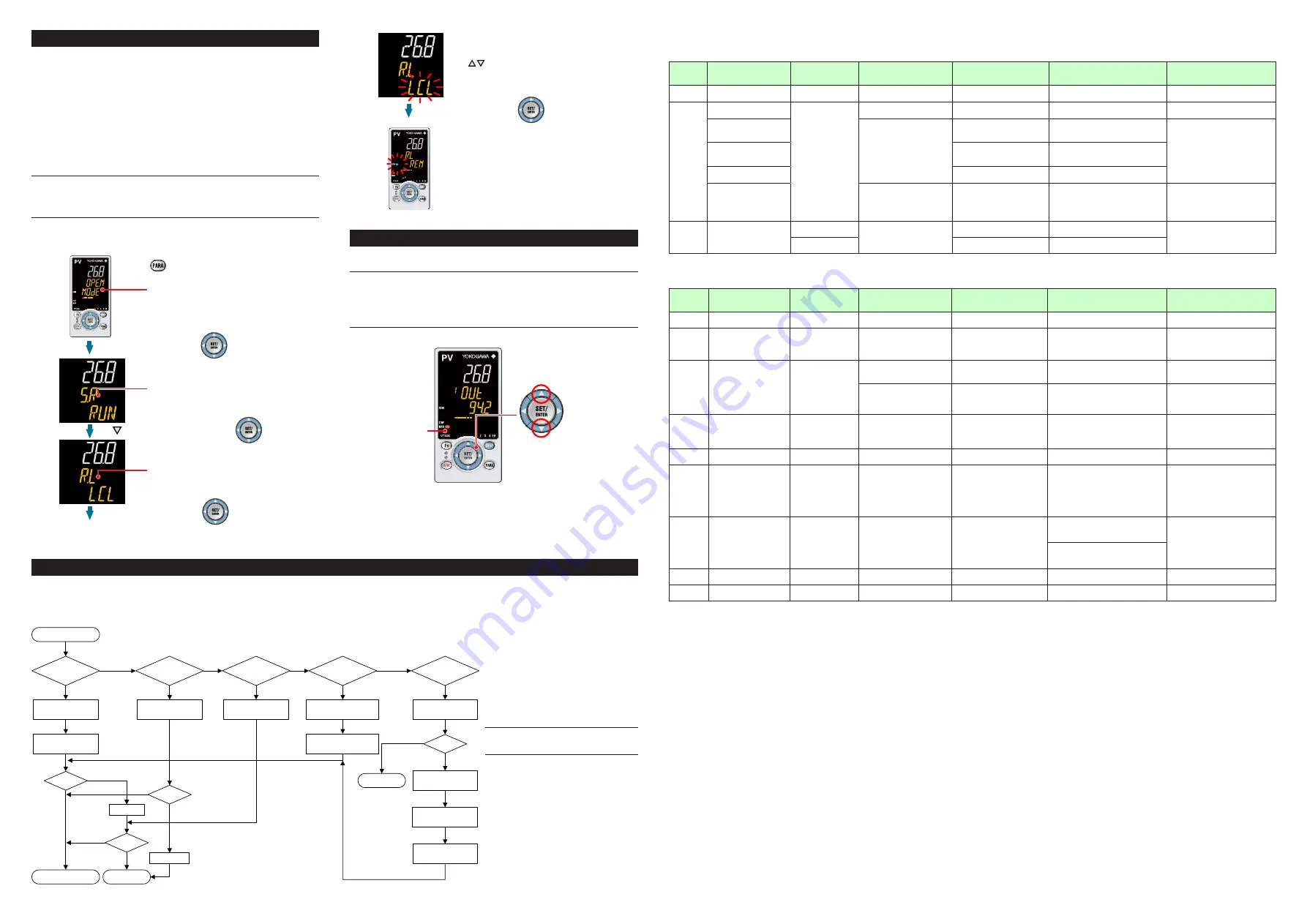

7. Switching between REM (Remote) and LCL (Local)

Remote and local switching can be performed using any of the following:

(1) Parameter, (2) Communication, and (3) User function key.

LCL (Local)

Control is performed using the target setpoint set on the controller.

REM (Remote)

Control is performed using a setpoint via communication for the target setpoint. The

following shows an example of switching from local to remote using the parameter.

(Only in cases where the communication is specified.)

For details of other switching methods, see User’s Manual (IM 05P01F31-01EN).

• The PID group for the local SP number is used as PID in remote mode.

NOTE

When the contact input is ON, operation cannot be performed using the parameter,

communication, or key. When the contact input is OFF and the setting is switched

using the parameter, communication, or key, the last switching operation is per-

formed.

1.

2.

4.

5.

6.

Show the Operation Display.

Hold down the PARA key

for 3 seconds to display MODE menu.

Press the SET/ENTER key.

Press the SET/ENTER key.

The REM lamp is lit.

Change the operation mode using

the Up/Down arrow keys.

Blinks during the change.

Press the SET/ENTER key.

The parameter R.L (REMOTE/LOCAL switch)

is displayed.

3.

Press the Down arrow key until

the parameter R.L appears.

The parameter S.R (STOP/RUN switch)

is displayed.

1.

2.

4.

5.

6.

Show the Operation Display.

Hold down the PARA key

for 3 seconds to display MODE menu.

Press the SET/ENTER key.

Press the SET/ENTER key.

The REM lamp is lit.

Change the operation mode using

the Up/Down arrow keys.

Blinks during the change.

Press the SET/ENTER key.

The parameter R.L (REMOTE/LOCAL switch)

is displayed.

3.

Press the Down arrow key until

the parameter R.L appears.

The parameter S.R (STOP/RUN switch)

is displayed.

8. Manipulating Control Output in Manual Mode

NOTE

In manual mode, control output is manipulated by operating the keys (the value is

changed using the Up/Down arrow keys, then outputted as it is).

Even if the SET/ENTER key is not pressed, the control output value changes ac-

cording to the displayed value.

In stop mode (when the STOP lamp is lit), control output cannot be manipulated.

MAN lamp is lit.

Up arrow key: increases control

output.

Down arrow key: decreases

control output.

9. Troubleshooting

■ Troubleshooting Flow

If the Operation Display does not appear after turning on the controller’s power, check the procedures in the following flowchart.

If a problem appears to be complicated, contact our sales representatives.

Is the controller

defective?

Contact us for repair. Problem solved.

No communication

capability

Completely

inactive?

Yes

Yes

Yes

No

No

No

Key

operation

failure?

Yes

No

Yes

Check wiring of the

power terminals.

Check the key lock

setting.

Display

failure?

*

Yes

No

Turn off power, and

then turn it on again.

I/O signal

failure?

Yes

No

Check the

supply voltage.

Check the

specifications and polarity

of connected devices .

Check the communication-

related parameters.

Check the specifications

of communication

devices.

Check the

communication wiring.

Communication

failure?

No

With

communi-

cation?

Yes

Yes

Normal?

Is the

key locked?

Check the specifications

of the controller.

Yes

No

Correct?

Correct the error(s).

Cancel the setting.

Check the I/O specifications

of the controller.

* The LCD (a liquid crystal display) is used for

a display portion of this product.

The LCD has a characteristic that the display action

becomes late at the low temperature.

Additionally, the luminance and contrast degradation

are caused due to aged deterioration.

However, the control function is not affected.

■

Remedies if Power Failure Occurs

during Operations

• Instantaneous power failure within 20 ms.

A power failure is not detected. Normal

operation continues.

• Power failure for less than about 5 seconds,

or for about 5 seconds or more.

Affects the "settings" and "operation status."

For details, see User's Manual (IM

05P01F31-01EN).

NOTE

Write down the settings of parameters for a

repair request.

■

Errors at Power On

The errors shown below may occur in the fault diagnosis when the power is turned on. (For details of Setpoint display and input/output action when each error occurs, see User’s Manual (IM

05P01F31-01EN).)

PV display

(Operation

Display)

Setpoint display

(Operation Display)

Status indicator

(Operation Display)

Parameter that displays error

details

Error description

Cause and diagnosis

Remedy

Indication off Indication off

—

—

Faulty MCU RAM / MCU ROM

MCU RAM / MCU ROM are failed.

Faulty.

Contact us for repair.

ERR

SYS - - - - -

—

—

System data error

System data is corrupted.

Faulty.

Contact us for repair.

PAR 0004

(for user default value error

only)

Setup parameter (PA.ER)

User (parameter) default value

error

User parameter is corrupted.

Initialized to factory default value.

Check and reconfigure the initialized

setting parameters. Error indication is

erased when the power is turned on

again.

PAR 0010

(for setup parameter error

only)

Setup parameter error

Setup parameter data is corrupted.

Initialized to user default value.

PAR 0020

(for operation parameter error only)

Operation parameter error

Operation parameter data is corrupted.

Initialized to user default value.

SLOT 0001

(0001: Error occurs to all

hardware of E1-terminal

areas.)

Setup parameter (OP.ER)

Nonresponding hardware of

extended function (E1-terminal

areas)

Inconsistence of system data and

hardware of extended function.

Nonresponding communication between

hardware of extended function (E1-terminal

areas).

Faulty.

Contact us for repair.

Normal

indication

Normal indication

Rightmost decimal point

on PV display blinks.

Setup parameter (PA.ER)

Calibration value error

Initialized to calibrated default value because

of corrupted factory default value.

Faulty.

Contact us for repair.

Rightmost decimal point

on Symbol display blinks.

Faulty FRAM

Data writing (storing) to FRAM is impossible.

■

Errors during Operation

The errors shown below may occur during operation. (For input/output action when each error occurs, see User’s Manual (IM 05P01F31-01EN).)

PV display

(Operation

Display)

Setpoint display

(Operation Display)

Status indicator

(Operation Display)

Parameter that displays

error details

Error description

Cause and diagnosis

Remedy

AD.ERR

Normal indication (Note)

—

Setup parameter (AD1.E)

Analog input terminal ADC error

•PV input

Analog input terminal AD value error

Faulty.

Contact us for repair.

RJC.E

(Displays RJC.

E and PV

alternately.)

Normal indication (Note)

—

Setup parameter (AD1.E)

Universal input terminal RJC error

•PV input

Universal input terminal RJC error

Faulty.

Contact us for repair.

Set the parameter RJC to OFF to erase

error indication.

B.OUT

Normal indication (Note)

—

Setup parameter (AD1.E)

Analog input terminal burnout error

•PV input

Analog input terminal sensor burnout

Check wiring and sensor.

Error indication is erased in normal

operation.

Setup parameter (PV1.E)

PV input burnout error

Burnout of analog input connected to PV

Check wiring and sensor of connected

analog input terminals.

Error indication is erased in normal

operation.

OVER

-OVER

Normal indication

—

Setup parameter (PV1.E)

PV input over-scale

PV input under-scale

(PV values out of -5 to 105%)

PV input is out of -5 to 105%. Also occurs

when the data out of range which is the

ladder calculation result is input.

Check analog input value or ladder

program.

AT.E

Normal indication

—

Setup parameter (PV1.E)

Auto-tuning time-out

Auto-tuning does not end even when 24

hours have elapsed after the start of tuning.

Check the process. Hold down any key to

erase the error indication

Normal

indication

0.000 00000

(Decimal point on the left of

the Symbol display blinks)

—

Setup parameter (OP.ER)

Communication error

(RS-485 communication)

Framing parity error

Buffer overflow

Inter-character time-out

Checksum error (PC link communication with

checksum)

CRC check error (Modbus/RTU)

LRC check error (Modbus/ASCII)

Check the communication parameters.

Recovery at normal receipt.

Hold down any key to stop blinking.

Normal

indication

0.000 00000

(Decimal point on the left of

the Symbol display blinks)

—

Setup parameter (OP.ER)

Communication error

(coordinated operation)

Inconsistence of loop between coordinated

master and slaves

Check the communication parameters.

Recovery at normal receipt. Change from remote

to local mode to stop blinking.

When the mode is changed from remote to

local, SP tracking does not work even if it is

set to ON.

Communication from coordinated master is

interrupted for 2 seconds.

Normal

indication

Normal indication

Rightmost decimal point on

Symbol display blinks.

Setup parameter (PA.ER)

Faulty FRAM

Writing (storing) data to FRAM is impossible. Faulty. Contact us for repair.

Undefined

Undefined

—

—

Faulty MCU / DCU

(ROM / RAM error, corrupted)

MCU / DCU is corrupted.

Faulty. Contact us for repair.

Note: When an error occurs in input shown in Analog input display (Operation display), Setpoint display shows the same symbol as the PV display.