IM 05F01F12-01E 3rd Edition Mar. 14, 2016-00

3

7.

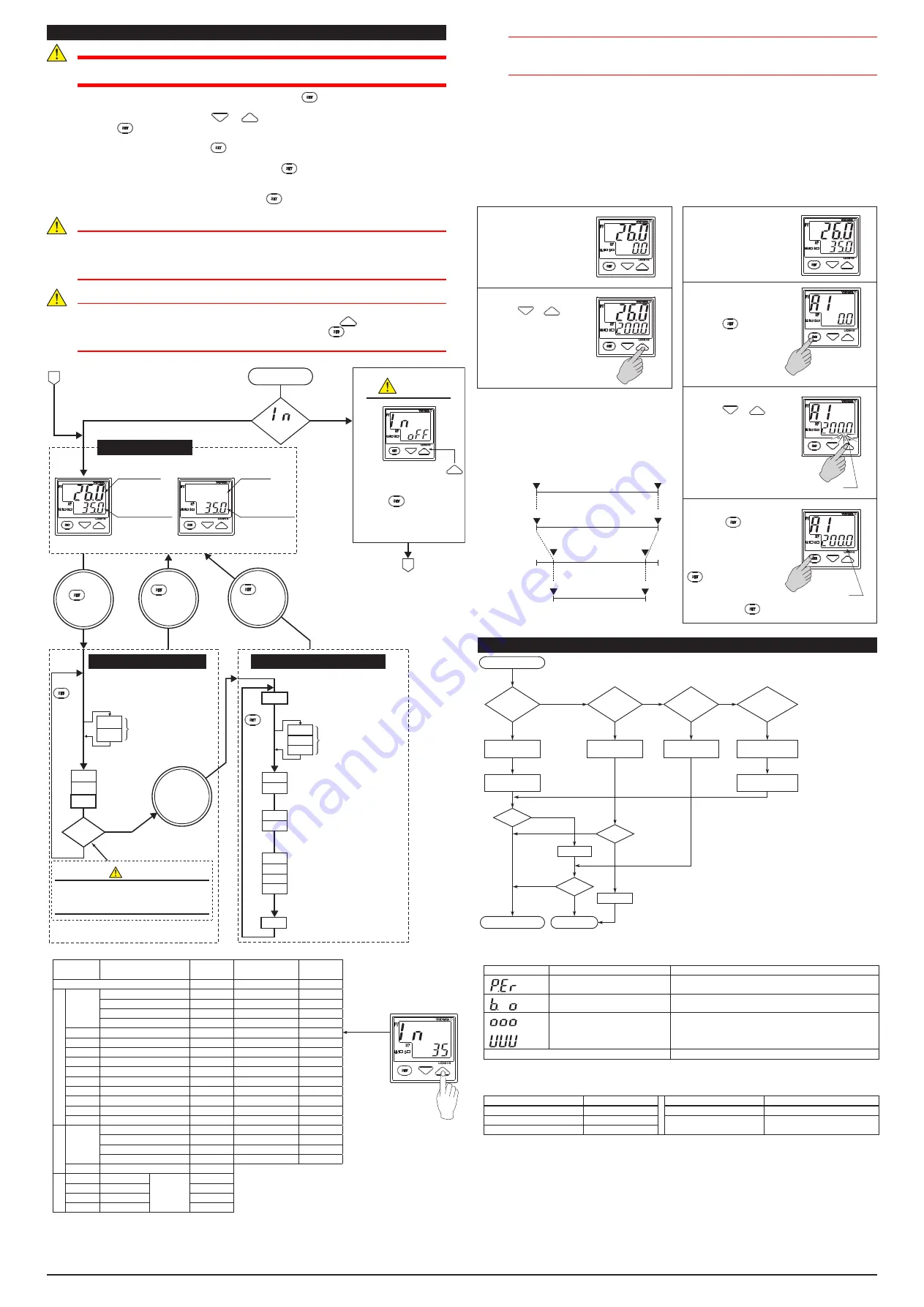

Key Operations

WARNING

To prevent electric shock, the manual setter should be mounted on the panel so as not

to accidentally touch the terminals when power is being applied.

(1) You can move between parameter setting displays using the

key.

(2) To change the parameter setpoint,

(i) Change the display value with the

or

key (the period flashes).

(ii) Press the

key to register the setpoint.

(3) In the operating display, pressing the

key for at least 3 seconds retrieves the operating

parameter setting display.

(4) In the operating parameter setting display, pressing the

key for at least 3 seconds transfers

back to the operating display.

Registering the key-lock parameter LOC to “–1” retrieves the setup parameter setting display.

(5) In the setup parameter setting display, pressing the

key for at least 3 seconds transfers back

to the operating display.

CAUTION

Changing certain setup parameters may automatically initialize the operating

parameters. Therefore, after you change the setup parameters, always check the

operating parameter setpoints to find out if appropriate values have been set for them. If

the operating parameters have been initialized, set them to their appropriate values.

CAUTION

At power-on, the manual setter displays the operating display, but if the measured input

type setting remains OFF, “IN” appears. In this case, press the

key to display the

measured input range code you want to use, then press the

key to register it. (Refer

to the flowchart below.)

is displayed

?

When measured input range code has been already set,

the operating display shown below appears.

Yes

No

Note: If no key is pressed for a period

of two minutes or more while in

the operating or setup parameter

setting display, the manual setter

automatically returns to operating

display.

• Displayed when AL1, AL2 = 1 to 20

LOC=

When

–1

When LOC=–1,

transfers to the

setup parameter

setting display

Press the

key

to move

between items.

When “In” appears, press the

key to display the measured input

range code you want to use, then

press the key to register it.

After this operation, the manual

setter shows the operating

display.

CAUTION

Set

″

-1

″

to enter the setup parameter setting display. But

if

″

LOC=1 or 2

″

is already set, the parameter value can

not be changed by setting

″

LOC=-1

″

only. To change the

parameter value, set

″

LOC=0

″

at first (for disabling

keylock), then set

″

LOC=-1

″

once again.

Operating Display

Set the parameters

as follows not to

display a measured

input value.

Measured input type (IN):

DC voltage input (20 to 23)

PV/SP display (PVD)

: OFF

TIP

Power ON

A

Operating Parameter Setting Display

Setup Parameter Setting Display

A1

A2

FL

BS

LOC

SPH

SPL

Displayed when DC voltage

input range code (20 to 23)

is set

DP

RH

RL

IN

AL1

AL2

HY1

HY2

PVD

CAUTION

A

RTH

RTL

Measured input

value(PV)

Target setpoint(SP)

No display

Target setpoint(SP)

Press the

key

for at least

3 seconds.

Press the

key

to move

between items.

Press the

key for

at least 3 seconds.

(To operating

display)

Note

Press the

key for

at least 3 seconds.

(To operating

display)

Note

At first

When parameter PVD=ON

(factory-set default)

When parameter PVD=OFF

● UD310 Measured Input Type and Ranges

Input type

Range (°C)

Range

code (°C)

Range (°F)

Range

code (°F)

For example, to select

thermocouple type J (°F),

set the range code to 35.

Unspecifed

OFF

Thermocouple

K

–270 to 1370°C

1

–300 to 2500°F

31

0.0 to 600.0°C

2

32.0 to 999.9°F

32

0.0 to 400.0°C

3

32.0 to 750.0°F

33

–199.9 to 200.0°C

4

–300 to 400°F

34

J

–199.9 to 999.9°C

5

–300 to 2100°F

35

T

–199.9 to 400.0°C

6

–300 to 750°F

36

E

–199.9 to 999.9°C

7

–300 to 1800°F

37

R

0 to 1700°C

8

32 to 3100°F

38

S

0 to 1700°C

9

32 to 3100°F

39

B

0 to 1800°C

10

32 to 3200°F

40

N

–200 to 1300°C

11

–300 to 2400°F

41

L

–199.9 to 900.0°C

12

–300 to 1600°F

42

U

–199.9 to 400.0°C

13

–300 to 750°F

43

Platinel 2

0 to 1390°C

14

32 to 2500°F

44

RT

D Pt100

–199.9 to 850.0°C

15

–199.9 to 999.9°F

45

0.0 to 400.0°C

16

32.0 to 750.0°F

46

–199.9 to 200.0°C

17

–300 to 400°F

47

–19.9 to 99.9°C

18

–199.9 to 999.9°F

48

JPt100

–199.9 to 500.0°C

19

DC voltage

0 to 100mV

0.0 to 100.0

User-scalable

20

0 to 5V 0.000 to 5.000

21

1 to 5V 1.000 to 5.000

22

0 to 10V

0.00 to 10.00

23

IMPORTANT

The manual setter is shipped with the parameters set at the factory-set defaults. Check

the default values against the “Parameter Lists” in the following page, and change the

parameter setpoints that need to be changed.

This section explains how to set and register parameter setpoints.

The procedure for changing Target Setpoint(SP) and Alarm 1 Setpoint(A1) can be found on

"Changing Target Setpoint(SP)" and "Changing Alarm 1 Setpoint(A1)".

You can set the other parameters in the same way.

The following instructions assume that the manual

setter is already receiving power.

SP (target setpoint) value will be output in 3

seconds after the change.

Check alarm type before setting the alarm setpoint.

Factory-set settings:

Alarm 1 type : OFF

Alarm 2 type : OFF

Step 1:

Confirm that the manual

setter shows the operating

display during normal

operation (PV and SP are

displayed on the indicators).

Step 1:

Confirm that the manual

setter shows the operating

display during normal

operation (PV and SP are

displayed on the indicators).

Step 2:

Press the or key

to change the SP display

value to the required

setpoint. In this example,

SP is changed to 200°C.

Step 2:

To enter the operating

parameter setting display,

press the key for at

least 3 seconds.

Press for at least 3 seconds.

Step 3:

Press the or key to

change the current A1

setpoint to a required

setpoint. In this example, A1

is changed to 200°C.

The period flashes while the setpoint is being changed.

Step 4:

Press the key once to

register the setpoint.

The period goes out.

A1 is now changed.

Another press of the

key calls up the Alarm 2

setpoint(A2) display.

To return to the operating

display, press the key for at least 3 seconds.

The period goes out.

n

Changing Target Setpoint (SP)

n

Changing Alarm 1 Setpoint (A1)

Measured input range

Target setpoint range

(Factory-shipped settings)

Target setpoint range

(after scaling)

SPL

SPL

Minimum value

of measured input

range (scale)

Maximum value

of measured input

range (scale)

SPH

4mA

20mA

SPH

Manual setting output

(4 to 20mA)

8. Troubleshooting

Is the manual setter defective?

Completely inactive?

Normal?

Contact us for repair

Problem solved

Cancel the setting

Key operation failure?

Is the key

locked?

Normal?

Correct it

Check the terminal connection

of the power supply

Check key-lock

setting

Display failure?

I/O signal failure?

Turn the power off,

then on

Verify the I/O spec.

of manual setter

Verify the spec. of

I/O destinations

Check the power

supply voltage

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

In the event of an abnormality, perform the following checks as outlined by the flowchart.

■

Error Display during Operation

(1) If the manual setter displays one of the following, carry out the appropriate remedy for the

particular error.

Display

Error content

Remedy

P.Er The parameter is abnormal

Check the setpoints of all the parameters and set them at

their proper values.

B.o Input burnout

Check the sensor wiring and correct it.

Not display when the setup parameter PVD=OFF.

OOO

PV over-scale

(PV exceeds its effective range.)

Check the measured input type and scale settings and

correct them.

Not display when the setup parameter PVD=OFF.

UUU

PV under-scale

(PV falls below its effective range.)

No PV display

Set the setup parameter PVD=ON to display PV.

(2) The manual setter needs to be repaired if any of the indications in the table below appear.

In these cases, do not try to repair the manual setter yourself.

Order a new manual setter or contact us for repair.

Display

Error content

Display

Error content

Unknown (at power-on)

CPU failure

Flashing “Err” (at power-on) RAM or ROM failure

All extinguished (at power-on) Power source failure

Flashing “Err”

(during operation)

A/D converter failure,

RJC failure, or EEPROM failure

“Err” (at power-on)

Calibration abnormal

■

When Power Failure Occurred during Operation

●

Momentary power failures shorter than 20ms(or shorter than 1ms when “/V24” is specified) have

no effect on the manual setter operation (i.e., normal operation continues).

●

For power failures of 20ms or longer(or 1ms or longer when “/V24” is specified), however the

status will be as follows.

(The manual setter action at power recovery is the same as at power-on.)

• Alarm action: Continues (but alarms with a waiting action enter the waiting state once)

• Setting parameters: Maintained