10

ADJUSTMENTS

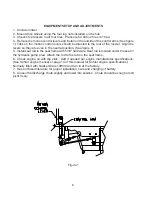

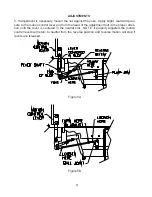

MOTION CONTROL LINKAGE ADJUSTMENT:

1. This adjustment must be made with the drive wheels rotating. Raise rear of the unit and

block it up so the wheels are free to rotate. CAUTION: Keep hands, feet and clothing away

from rotating tires.

2. Tilt seat forward and remove the seat rod from seat so the seat can rotate down onto the

frame. Make sure the seat is adjusted toward the rear of the unit so it clears the controls on

the console.

3. Place a 2x4 board approximatly 10 to 12 inches long between the foot plate and the center

of the seat to engage the seat safety switch. NOTE: You may want to cover the end of the 2x4

with a rag to protect the seat from marring.

4. The reverse spring detent must be adjusted correctly before the motion control linkages

may be adjusted.(See reverse spring detent adjustment section.)

5. Loosen the nuts directly behind each ball joint on both rods that connect the pump arm to

the motion control assemblies. (See Fig 5 )

6. Start the engine. The park brake must be engaged and the motion control levers must be

in the neutral slot (See figure 6 page10) to start the engine. Run engine at approximately 1/

2 throttle.

7. Release park brake to allow wheels to rotate. CAUTION: Keep hands, feet and clothing

away from rotating tires.

8. Begin with either side and put the motion control lever into the neutral position. Adjust the

motion control linkage by rotating the double nuts on the rod in the proper direction until the

wheel stops rotating (See Fig 5 ).

Move the motion control lever forward then into the neutral position and place it into the

neutral slot. The wheel must be stopped completely at this point. Now do the same in reverse

and release the lever. The lever should return to neutral on its own. If not see reverse spring

detent adjustment section.

9. Run engine at full throttle to make sure wheels do not rotate. Readjust if any rotation

occurs.

10. Repeat on the opposite side and tighten nuts against ball joints.

11. Remove the 2x4 board and make sure the seat wiring is connected to the wiring harness.

WARNING: Seat must be connected for safety interlock system to properly function.

OPERATING INSTRUCTIONS

CONTROLS:

1. Be thoroughly familiar with all controls their function and how to operate them before

operating the mower.

2. Motion control levers located on each side of the console control direction of movement.

The left lever controls the flow of oil from the left hydro pump to the left wheel motor. The right

lever controls the flow of oil from the right hydro pump to the right wheel motor.

Summary of Contents for ZKH52222

Page 17: ...17 WIRING DIAGRAM...

Page 18: ...18 SERVICE RECORD DESCRIPTION OF WORK DONE DATE SERVICE DONE BY...

Page 21: ......