10.1 Specifications of Robot Interface Signals

10-1

HW0480311

HW0480311

10

Robot Interface Signals

10.1

Specifications of Robot Interface Signals

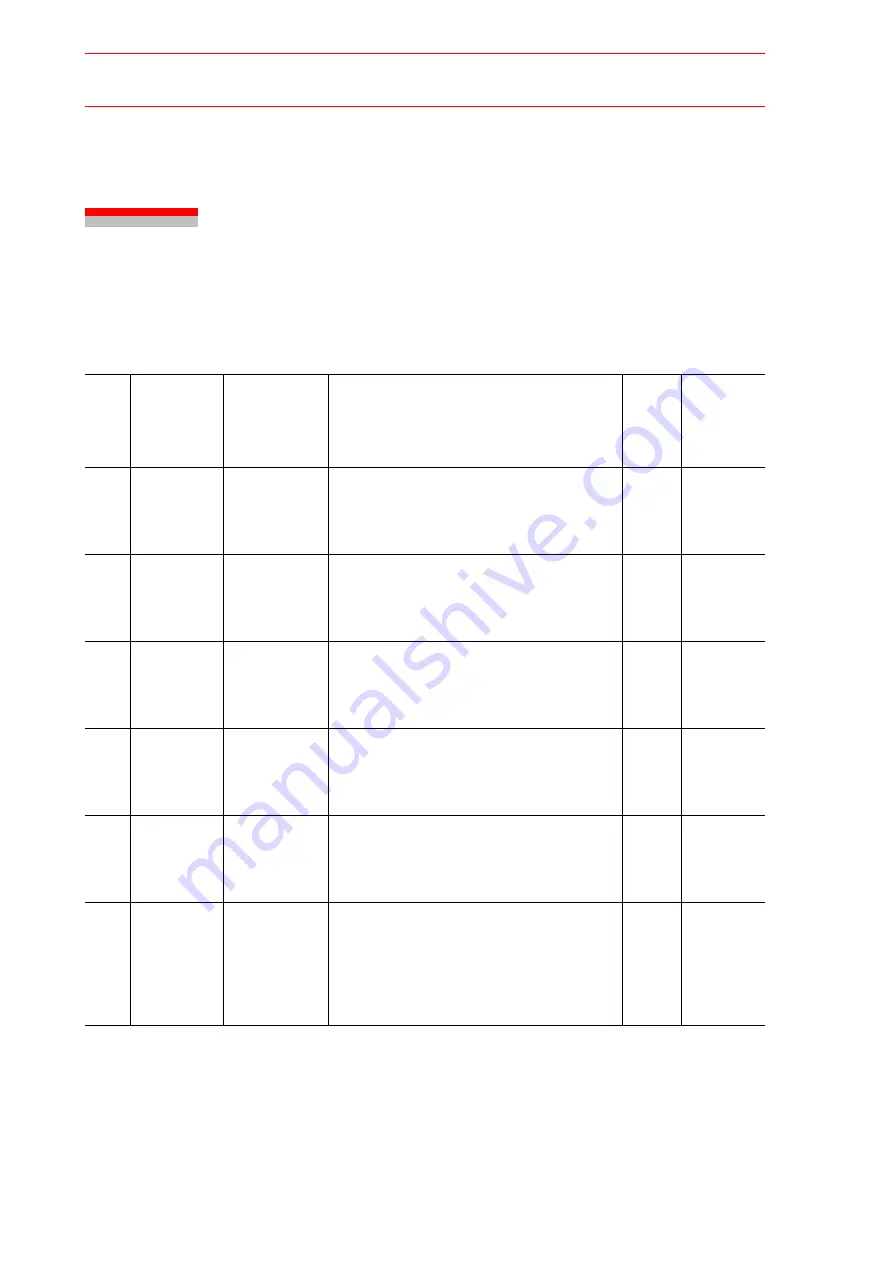

The following table shows the correspondence of the pin number and the signal of connector

CON3 (26 pins).

For signal systems, refer to

“

11. Conncetion System Diagram.

”

No.

Pin No.

Correspon

ding to

Connector

Signal

Meaning

Function

Direct

ion

*1

Signal

Form

1

A

- B

(0V side)

Arc voltage

adjustment

instruction

Gives the compensation value of the arc

voltage when set to

"

Synergic.

"

(When set to

"

independent,

"

the arc volt-

age is sent directly.)

R

→

W

Analog

voltage

input of

0V to 14V

2

C

- D

(0V side)

Welding cur-

rent instruc-

tion

Gives the set value of the output current

(wire feeding amount) for the welding

source.

R

→

W

Analog

voltage

input of

0V to 14V

3

F

- G

Wire inching

instruction

Performs the wire inching.

R

→

W

Contact

input

(Valid at

closed)

4

H

- J

Wire retract

instruction

Withdraws the wire.

R

→

W

Contact

input

(Valid at

closed)

5

K

- L

ARCON/

ARCOF

instruction

Instructions to start/stop the welding.

R

→

W

Contact

input

(Valid at

closed)

6

M

- N

("-" side)

Wire stick

detection

Sends the output terminal voltage of the

welding source.

The wire stick detection voltage

(approx.15 V) is input from the robot side.

W

→

R

Welding

source

output

voltage

(Analog

value)

80/129