3.5 Wiring the Power Supply to the SERVOPACK

3.5.2 Wiring Procedure for Main Circuit Connector

3

Wiring and Connection

s

3-27

You can use a single-phase, 200-VAC power supply input with the following models.

•

SGD7C-1R6A, -2R8A, and -5R5A

If you use a single-phase, 200-VAC power supply input for the SERVOPACK’s main circuit

power supply, set parameter Pn00B to n.

1

(Use a three-phase power supply input as a

single-phase power supply input). Refer to the following section for details.

5.3.2 Single-phase AC Power Supply Input/Three-phase AC Power Supply Input Setting

•

DC Power Supply Input

If you use a DC power supply input to the SERVOPACK, set Pn001 to n.

1

(Input DC

power) before inputting the power supply. Refer to the following section for details.

5.3.1 AC Power Supply Input/DC Power Supply Input Setting

3.5.2

Wiring Procedure for Main Circuit Connector

•

Required Items

1.

Remove the main circuit connector and motor connector from the SERVOPACK.

2.

Remove the sheath from the wire to connect.

Terminal

Symbols

Terminal Name

Specifications and Reference

L1C and L2C

Control power supply termi-

nals

L1C: 270 VDC to 324 VDC, -15% to +10%, L2C: 0 VDC

Or

L2C: 270 VDC to 324 VDC, -15% to +10%, L1C: 0 VDC

B1/

Main circuit power supply

input terminals for DC

power supply input

270 VDC to 324 VDC, -15% to +10%

2

0 VDC

L1, L2, L3,

B2, B3, 1,

and

–

None. (Do not connect anything to this terminal.)

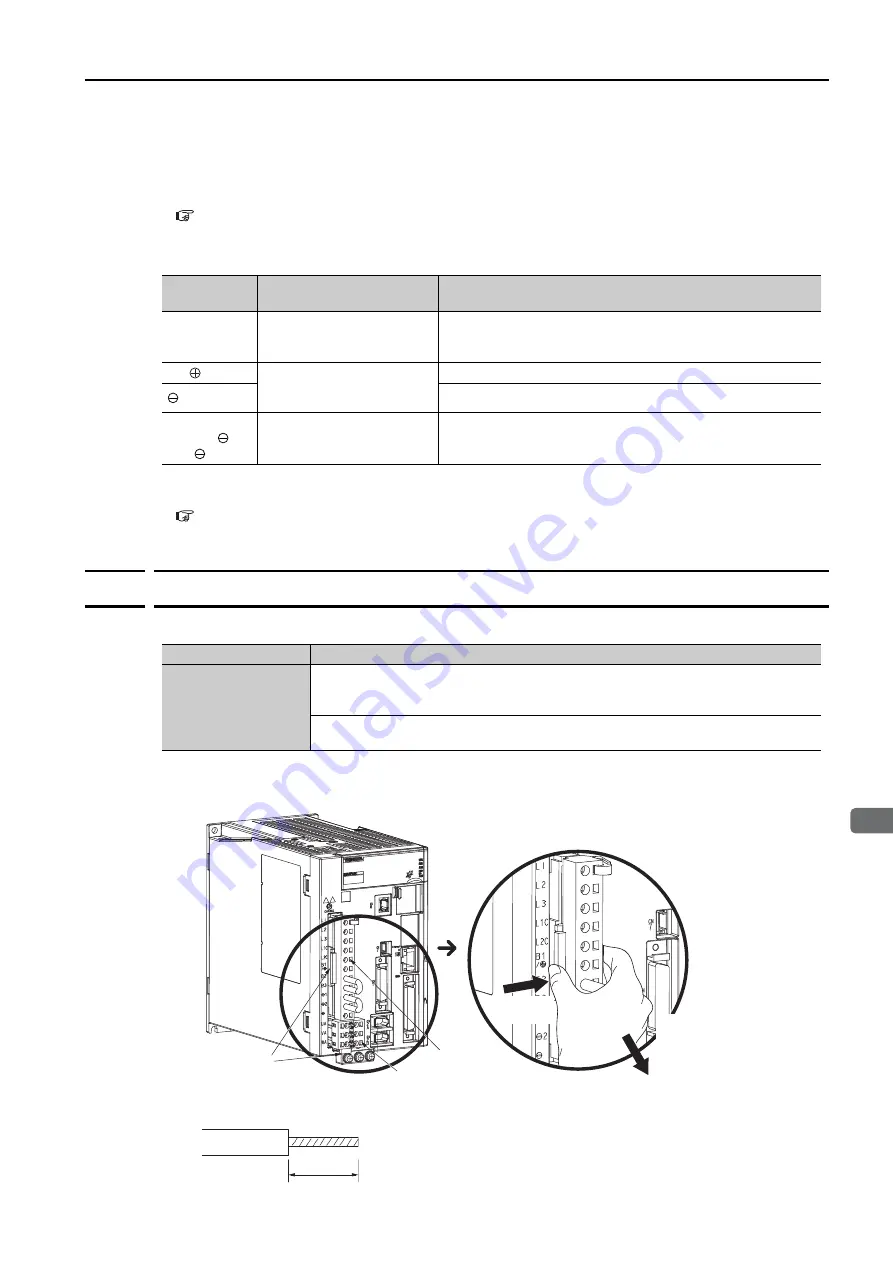

Required Items

Remarks

Spring Opener or Flat-

blade Screwdriver

•

Spring Opener

SERVOPACK accessory

(You can also use model 1981045-1 from Tyco Electronics Japan G.K.)

•

Flat-blade screwdriver

Commercially available screwdriver with tip width of 3.0 mm to 3.5 mm

Lock

s

1. Pre

ss

in

on the lock.

2. Pre

ss

in on the lock

s

to

remove the connector

s

.

Enlarged View

Main circuit

connector

S

ervomotor connector

8 mm to 9 mm