Internal cables and compressed air lines

8

-

45

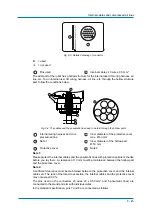

Fig. 8-3: Detailed drawing of connector

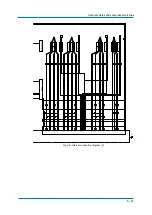

The wrist part of the robot has a hollow structure for the internal user I/O wiring harness, air

line, etc. To run internal user I/O wiring harness, air line, etc. through the hollow structure

part, follow the conditions below.

Fig. 8-4: The cables and the pneumatic line need to be laid through the hollow parts

Note 1:

Please protect the internal cables and the pneumatic lines with protection spirals or the like

before you lay them. A clearance of 10 mm must be maintained between the hollow part

and the protective cover.

Note 2:

A sufficient clearance must be maintained between the protective cover and the internal

cables etc. The ratio of the total-cross section, the internal cables and the protective cover

may not exceed 30 %.

The pins used on the connectors 23 wires 23 x 0.50 mm² and 5 pneumatic lines) are

connected to the stand and arm with individual wires.

In the standard specification, pins 7 and 8 are connected as follows:

= used

= not used

Pins used

Internal cables: 23 wires, 0.5 mm²

Internal wiring harness and com-

pressed-air line

Inner diameter of the protective cover

max. Ø 43 mm

Note 1

Inner diameter of the hollow part

Ø 53 mm

Protective cover

Note 2

8

4

9

6

5

1

7

2

3

14

19 20

15

17

11 12

18

13

21 22 23

10

16

P

P

P

P

P

P

P

P

P

P

P

1

6

5

3

4

2

7

8

9

10

15

14

13

12

11

20

19

17

18

16

22

23

21

2

1

1

2

1

3

4

5

6

2

1

4

2

5

3

6

Summary of Contents for MPL160-J00

Page 1: ...ROBOTICS MPL160 J00 YR MPL0160 J00 Operating and Maintenance Manual...

Page 36: ...Technical data 6 36 6 5 1 2 Stop position L axis 100 deflection deg deg s deg s sec...

Page 37: ...Technical data 6 37 6 5 1 3 Stop position U axis 100 deflection deg deg s deg s sec...

Page 61: ...Maintenance and inspection 9 61 Air outlet cap Joint 80 9 0 170 1 1 2 2 2 1 2...

Page 91: ...Parts lists 11 91...