6

Disassembly and Reassembly of the Speed Reducer

6.1

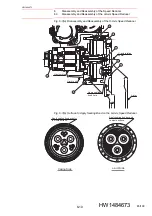

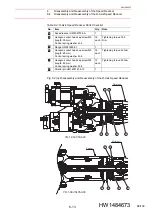

Disassembly and Reassembly of the S-Axis Speed Reducer

6-2

HW1484673

HW1484673

6. Tighten the hexagon socket head cap screws

and

with the

tightening torque shown in

. If the S-axis mechanical

stoppers

,

, and

were removed during disassembly, mount

them and tighten them with the tightening torque shown in

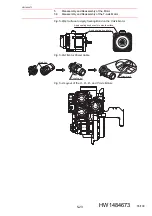

7. Reassemble and mount the S-axis motor

.

(Refer to

chapter 5.1 “Disassembly and Reassembly of the S-Axis

(When replacing the speed reducer, replace the input gear, too.)

8. Mount the internal wiring harness.

(Refer to

.)

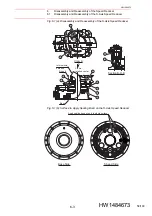

9. Replenish grease (Molywhite RE No.00) from the grease inlet. Mount

the hexagon socket head plugs at grease inlets and the grease

exhaust ports after the replenishment of grease. (Refer to

chapter 4.1.2 “Grease Exchange Procedure”

(S-axis).)

10. Turn ON the power supply of the YRC1000.

NOTE

If grease is filled before the sealing bond is solidified, it may

cause grease to leak. After tightening the screws, leave it

30 minutes or more, and then fill with grease.

Table 6-1: S-Axis Speed Reducer Parts Checklist

No.

Item

Qty.

Note

Speed reducer HW1382898-A

1

Hexagon socket head cap screw M12

(length: 45 mm)

Conical spring washer 2H-12

16

each

Tightening torque 142

N•m

Hexagon socket head cap screw M12

(length: 35 mm)

Conical spring washer 2H-12

2

each

Tightening torque 142

N•m

Parallel pin HW1405948-10-25

1

Hexagon socket head cap screw M20

(length: 40 mm)

1

S-axis mechanical

stopper

Tightening torque 167

N•m

Collar HW9405875-1

1

S-axis mechanical

stopper

Hexagon socket head cap screw M12

(length: 55 mm)

Conical spring washer 2H-12

12

each

Tightening torque 142

N•m

Union KQ2L10-01AS

1

S-axis motor

1

SGM7G-30APK-YR1*

Input gear HW0313741-1

1

2

3

5

6

7

9

1

2

3

4

5

6

7

8

9

11

10

57/109