8-46

155507-1CD

RE-CSO-A037

DX100

8 Parameter

8.6 Parameters according to Coordinated or Synchronized Operation

8.6.0.4 S2C232: JOB AT CALLING MASTER OF SUBTASK BY INDEPENDENT

CONTROL

This parameter specifies the job which is called up when the master of the

subtask is called up by independent control.

Master Job: Job registered in the master control window

Root Job: Job activated by PSTART instruction

8.6.0.5 S2C264: STATION AXIS CURRENT VALUE DISPLAY FUNCTION

This parameter specifies whether the function to display the current value

of the station axis in the following units is valid/invalid.

Rotary axis : Angle (deg)

Servo track : Distance (mm)

Regarding whether to specify the rotary axis or the servo track, refer to

section 8.6.0.6 “S2C265 to S2C288: STATION AXIS DISPLAYED UNIT”

.

8.6.0.6 S2C265

to

S2C288:

STATION AXIS DISPLAYED UNIT

This parameter specifies the station axis displayed unit (bit specification).

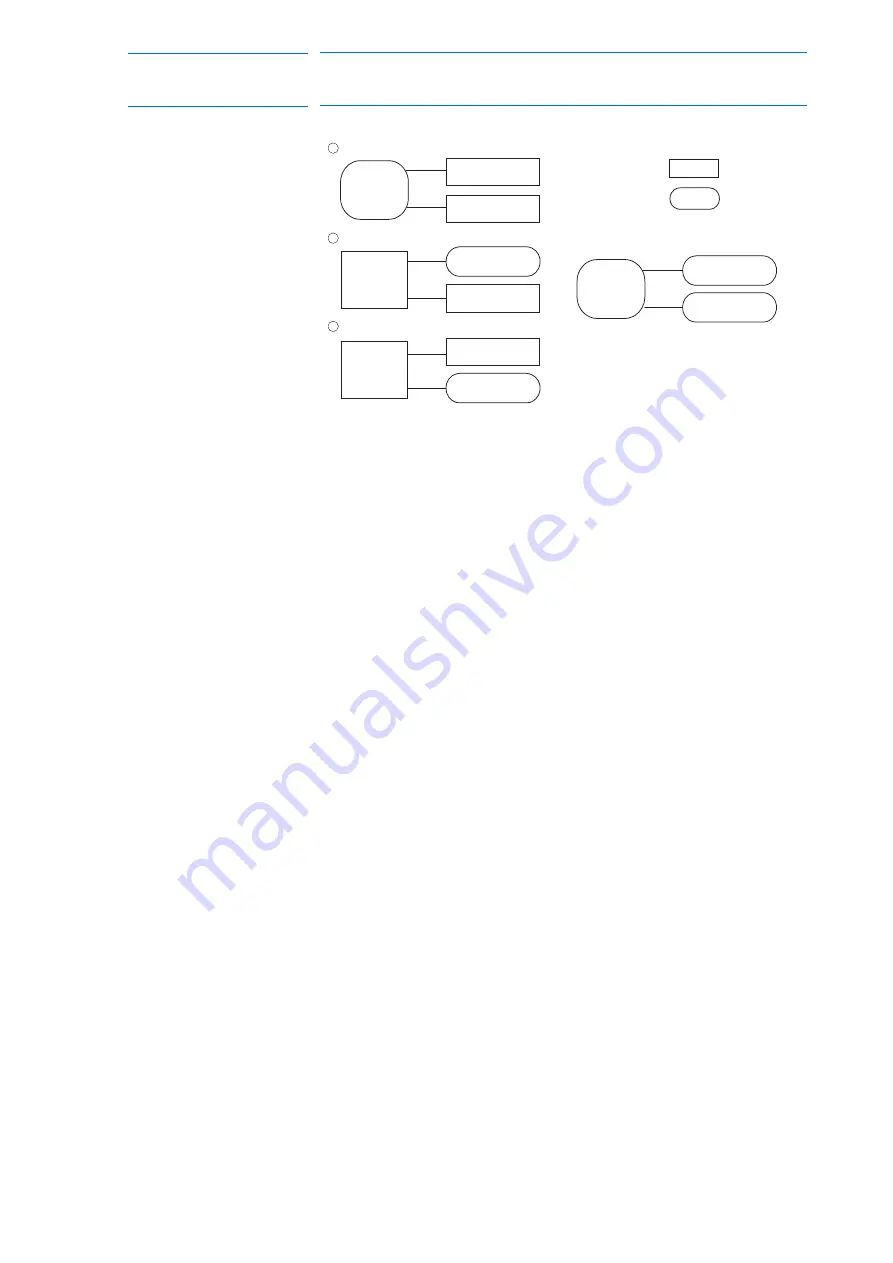

: Operating

0: One of the task jobs that are currently

displayed operates.

1: All task jobs operate.

Sub task 1

Master

task

Sub task 2

Master

task

Sub task 1

Sub task 2

: Not operating

Sub task 1

When master task is currently displayed:

1

When sub task 1 is currently displayed:

2

When sub task 2 is currently displayed:

3

Sub task 1

Sub task 2

Sub task 2

Sub task 1

Master

task

Master

task

0

: Master job

1

: Root job

0

: Invalid

1

: Valid

0

: Display angle (deg)

1

: Display in distance (mm)

477 of 554