RMB/ENERGIE GmbH | 25

assembly

Operation manual CHP 5.0 - 30.0 | Status 01.2020

5.3.9 Connecting the control cabinet

D

WARNING!

Risk of injury from electric shock!

The cables must be deenergised during assembly.

A

Deenergise the cables.

A

Ensure that the cables remain deenergised during

installation.

D

ATTENTION!

Risk of damage caused by the incorrect matching

of connectors!

Having the wrong polarity on the connection terminals

can seriously damage the control mechanism.

A

Pay attention to the correct polarity on the

connection terminals and to a right-rotating field.

All cables must be fed into the control cabinet through

the cable connections from underneath.

Use the enclosed wiring diagrams to identify the

connection terminals.

Wiring diagrams.

Please refer to the technical data for the permissible

cross-sectional areas of the supply lines.

Technical data.

A

Open the control cabinet.

A

Connect the temperature sensors (T1-T5).

A

Connect the modem.

The connection of additional components depends on

the heating system.

D

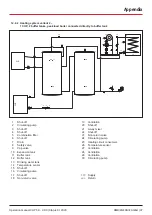

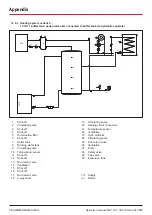

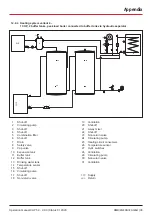

“12.2 Hydraulic diagrams” (page 35).

A

Connect any additional components (e.g. peak load

boiler, equipment of the building control technology)

to the control mechanism.

Once all components have been connected:

A

Make sure that the mains connection is

de-energised.

A

Connect the supply voltage to the control cabinet.

A

Close the control cabinet.

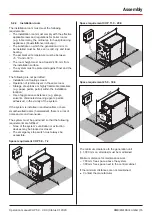

5.3.10 Checking the connections

Once the assembly process is complete, the following

points must be checked:

B

Leak-tightness of all lines.

B

Flexibility of all lines to the generation unit.

B

Tight fit of all connections in the control cabinet.

B

No damage, kinks or pinches in the cabling and

lines.

B

The siphon of the condensate drain is filled with

water.

B

Tension-free installation of all lines to the generation

unit.

A

Check the system.

If the exhaust air and flue gas are extracted together:

A

Ensure that the system is fitted with a suitable

exhaust air kit.

If the exhaust air or flue gas is extracted in combination

with another heat source (peak load boiler or another

system):

A

Ensure that the system is fitted with a suitable

backflow preventer.