ENGINE

3TNV88F Service Manual

6-23

Cylinder Head

■

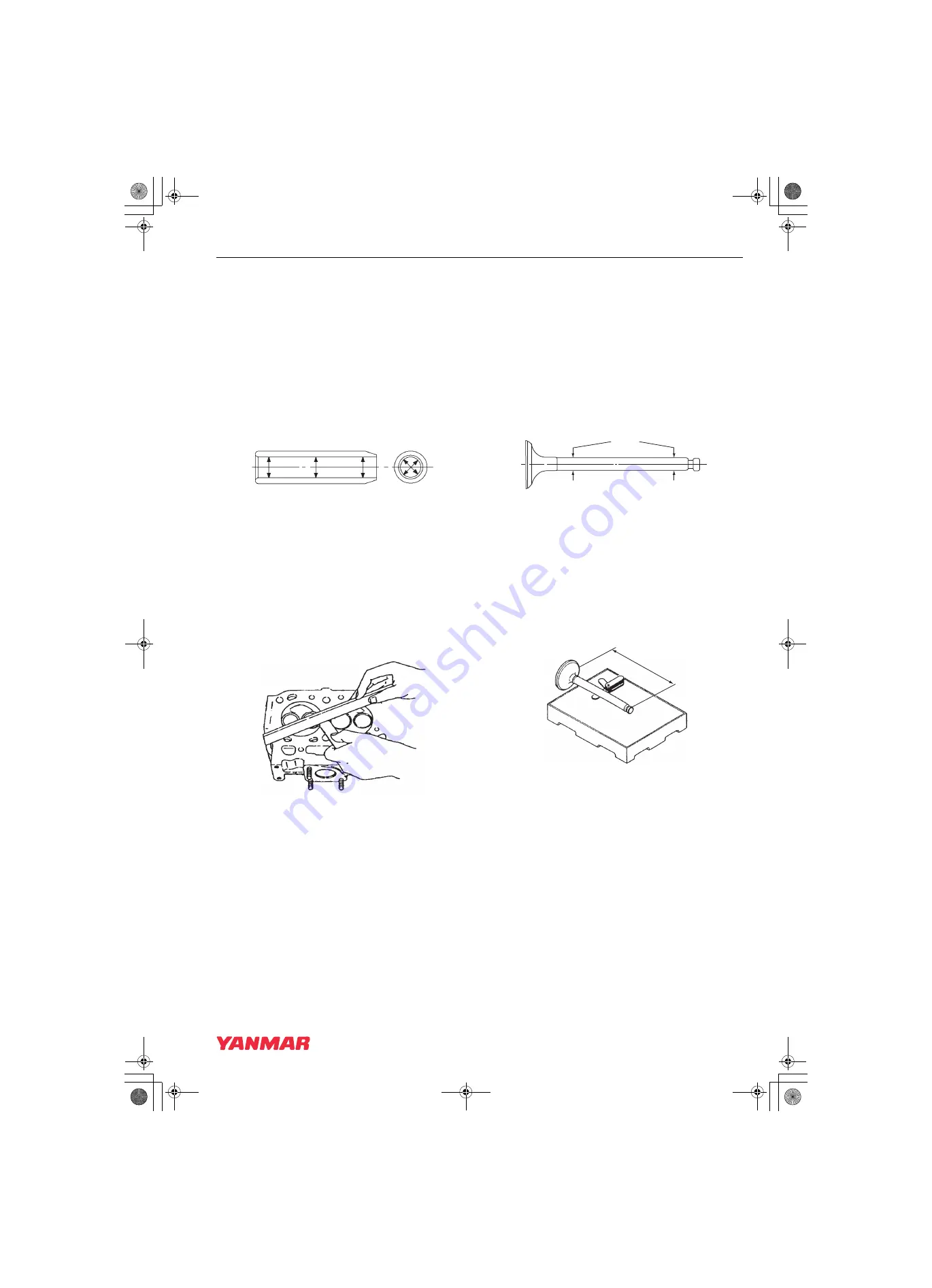

Inspection of valve guides

Visually inspect the valve guides for distortions,

scoring or other damage.

Note: Measure the valve guides while they are

installed in the cylinder head.

Use a telescoping gauge and micrometer to

measure the inside diameter at each end of the

valve guide. Measure in three places and 90° apart

See Intake/Exhaust Valve and Guide

on page 6-4 for the service limit.

Replace valve

guides if not within specification.

Figure 6-17

■

Inspection of cylinder head

Cylinder head distortion

Place the cylinder head flat and inverted

(combustion side up) on the bench. Use a straight

edge and a feeler gauge to measure cylinder head

distortion

. Measure diagonally and

along each side.

for the service limit.

Figure 6-18

If distortion exceeds the service limit, resurface or

replace the cylinder head. Remove only enough

material to make the cylinder head flat, but do not

remove more than 0.008 in. (0.20 mm).

■

Inspection of intake and exhaust valves

Visually inspect the intake and exhaust valves.

Replace any valves that are obviously discolored,

heavily pitted or otherwise damaged.

Valve stem diameter

Use a micrometer to measure the valve stem

diameter. Measure the valve stem near the

combustion end and near the opposite end

(Figure 6-19, (1))

Guide on page 6-4 for the service limit.

Figure 6-19

Valve stem bend

Place the valve stem on a flat inspection block or

layout bed. Roll the valve until a gap can be

observed between a portion of the valve stem and

the surface of the block or bed. Use a feeler gauge

to measure the gap

.

Intake/Exhaust Valve and Guide on page 6-4 for

the service limit.

Figure 6-20

K0001869

K0000192

K0000197

1

K0000199

3TNV88F_SVM_A4.book 23 ページ 2012年7月26日 木曜日 午後6時4分