– 90 –

–

+

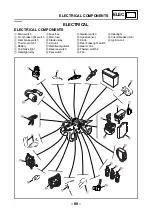

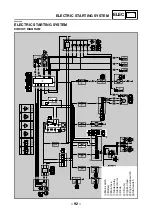

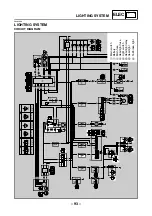

ELEC

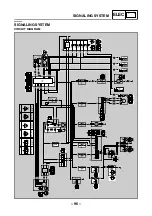

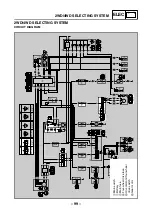

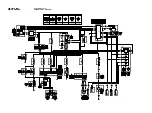

CHECKING THE SWITCH

CHECKING THE SWITCH CONTINUITY

Refer to “CHECKING THE SWITCH” and check for continuity between lead terminals.

Poor connection, no continuity

→

Correct or replace.

*

The coupler locations are circled.

L

B

Y

G

Br

L

/

B

(BLACK)

1

4

5

C

6

2

3

R

/

B R

/

W

PUSH

Br L Y G

B

R

/

W

Br

/

L Br

R

R

/

B

L

/

B

Br

/

R

L

/

R

L

/

B L

/

G

B

(GRAY)

ON

OFF

R

Br

Br

/

L

Br

Y

(BLACK)

7

B

B

(BLACK)

8

9

B

B

Br

/

R L

/

R L

/

G B L

/

B

2WD

4WD

B

A

0

Br

/

L

Br

R

/

W

R

ON

OFF

R

/

W

R

Br

Br

/

L

OFF