5-4

E

POWR

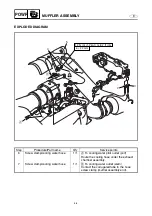

MUFFLER ASSEMBLY

EXPLODED DIAGRAM

Step

Procedure/Part name

Q’ty

Service points

6

Screw clamp/cooling water hose

1/1

È

To cooling water pilot outlet (port)

Route the cooling hose under the exhaust

chamber assembly.

7

Screw clamp/cooling water hose

1/1

É

To cooling water outlet (stern)

Contact the corrugated tube to the hose

screw clamp (muffler assembly end).

4

7

5

6

1

2

3

È

6

×

22 mm

12 N • m (1.2 kgf • m, 8.7 ft • Ib)

LT

242

É

Summary of Contents for WaveRunner GP1300R

Page 1: ...SUPPLEMENTARY SERVICE MANUAL GP1300R WaveRunner F1G 28197 1G 1X LIT 18616 02 90 LIT186160290...

Page 10: ...E TROUBLE ANALYSIS TROUBLE ANALYSIS 48 SELF DIAGNOSIS 48 WIRING DIAGRAM...

Page 61: ...YAMAHA MOTOR CORPORATION USA Printed in USA Dec 2004 0 0 1 CR E...

Page 62: ...SERVICE MANUAL GP1300R WaveRunner F1G 28197 1F 11 LIT 18616 02 44 LIT186160244...

Page 340: ...YAMAHA MOTOR CORPORATION USA Printed in USA Feb 2003 0 0 1 CR E...