ENGINE

3-8

• If an air screw was removed, turn the screw

3/4 turn in and be sure to synchronize the

throttle body.

TIP

• The difference in vacuum pressure between

two throttle bodies should not exceed 1.33

kPa (10 mmHg).

• If you are unable to adjust the throttle body

synchronization using this procedure, use

the following procedure instead.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Alternate procedure

TIP

Use this alternate procedure if you are unable

to adjust the throttle body synchronization

using the basic procedure.

a. Start the engine, warm it up for several

minutes, and then let it run at the specified

engine idling speed.

b. Turn all of the bypass air screws in fully.

c. Using the throttle body with the lowest vac-

uum pressure as the standard, turn out the

bypass air screws of the other throttle bod-

ies to adjust them.

TIP

• Do not turn out the bypass air screw of the

throttle body with the lowest vacuum pres-

sure.

• After each step, rev the engine two or three

times, each time for less than a second, and

check the synchronization again.

• If an air screw was removed, turn the screw

3/4 turn in and be sure to synchronize the

throttle body.

TIP

The difference in vacuum pressure between

two throttle bodies should not exceed 1.33 kPa

(10 mmHg).

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

7. Stop the engine and remove the measuring

equipment.

8. Allow the engine to cool, and then start the

engine and check that the engine speed

does not rise abnormally high.

9. Adjust:

• Throttle cable free play

Refer to “ADJUSTING THE THROTTLE

CABLE FREE PLAY” on page 3-8.

10. Install:

• Caps

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• Rider seat

Refer to “GENERAL CHASSIS” on page

4-1.

EAS20630

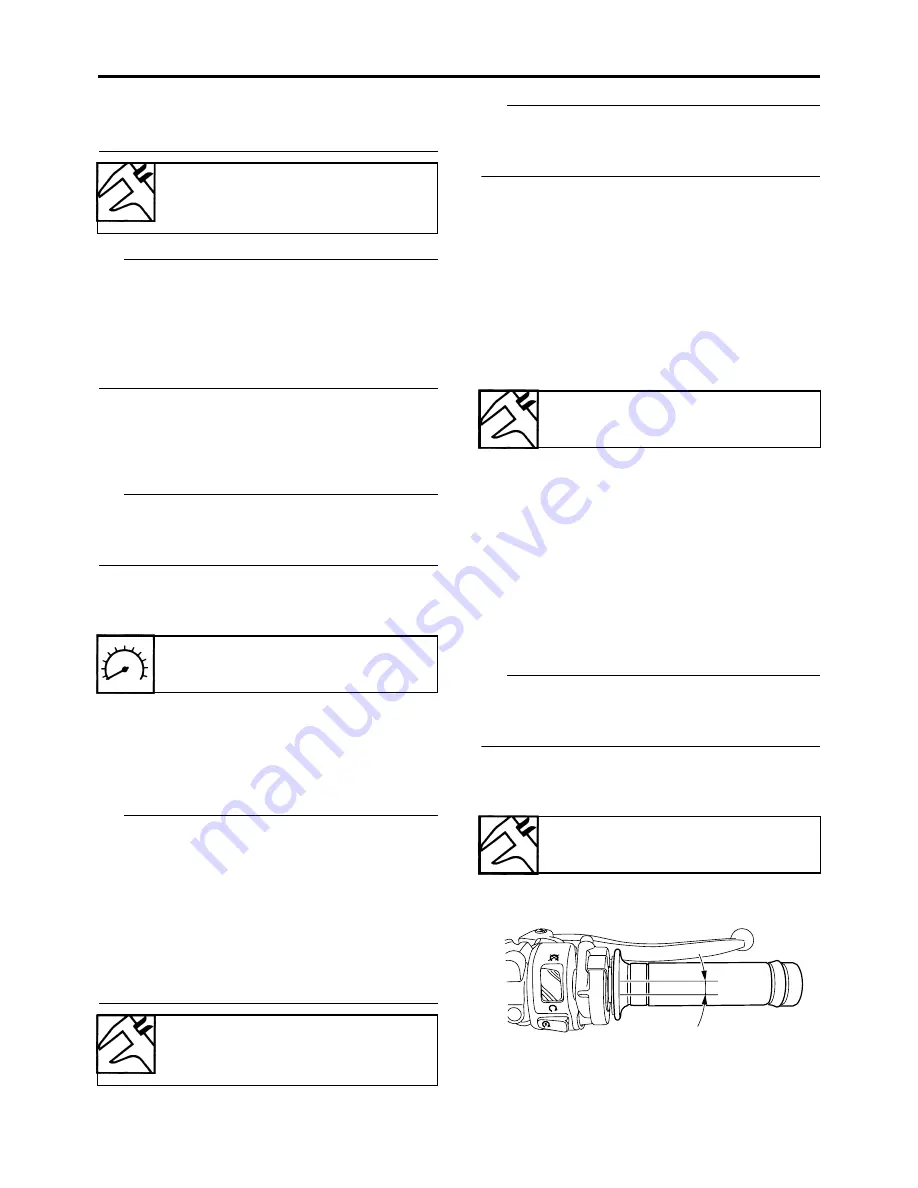

ADJUSTING THE THROTTLE CABLE FREE

PLAY

TIP

Prior to adjusting the throttle cable free play,

the engine idling speed and carburetor syn-

chronization should be adjusted properly.

1. Check:

• Throttle cable free play “a”

Out of specification

→

Adjust.

2. Adjust:

• Throttle cable free play

Intake vacuum

20.0 kPa (5.9 inHg) (150

mmHg)

Engine idling speed

1250–1350 r/min

Intake vacuum

20.0 kPa (5.9 inHg) (150

mmHg)

Throttle cable free play

3.0–5.0 mm (0.12–0.20 in)

Throttle cable free play

3.0–5.0 mm (0.12–0.20 in)

a

Summary of Contents for R6 2009

Page 1: ...SERVICE MANUAL YZFR6Y C 13S 28197 11 LIT 11616 22 51 2009 ...

Page 6: ......

Page 8: ......

Page 60: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29 EAS20410 LUBRICATION DIAGRAMS 1 2 3 4 ...

Page 62: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 31 1 2 3 4 8 7 6 5 ...

Page 64: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 33 1 2 3 4 5 ...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 35 1 5 4 3 2 ...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 37 3 1 2 5 4 ...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 39 1 3 2 ...

Page 71: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 40 1 Oil pipe 2 Main axle 3 Drive axle ...

Page 72: ...COOLING SYSTEM DIAGRAMS 2 41 EAS20420 COOLING SYSTEM DIAGRAMS 1 2 3 4 ...

Page 74: ...COOLING SYSTEM DIAGRAMS 2 43 A A 2 1 3 4 5 6 7 8 6 13 8 9 15 14 9 10 11 12 ...

Page 76: ...CABLE ROUTING 2 45 EAS20430 CABLE ROUTING ...

Page 78: ...CABLE ROUTING 2 47 ...

Page 80: ...CABLE ROUTING 2 49 ...

Page 82: ...CABLE ROUTING 2 51 ...

Page 84: ...CABLE ROUTING 2 53 ...

Page 86: ...CABLE ROUTING 2 55 ...

Page 88: ...CABLE ROUTING 2 57 ...

Page 90: ...CABLE ROUTING 2 59 A A ...

Page 92: ...CABLE ROUTING 2 61 ...

Page 95: ......

Page 135: ......

Page 206: ...CHAIN DRIVE 4 71 1 2 3 a a New ...

Page 209: ......

Page 240: ...PICKUP ROTOR 5 31 ...

Page 286: ...TRANSMISSION 5 77 ...

Page 300: ...WATER PUMP 6 13 ...

Page 316: ...AIR INDUCTION SYSTEM 7 15 EAS27040 AIR INDUCTION SYSTEM 2 1 2 4 3 4 3 6 4 5 A A ...

Page 323: ......

Page 324: ...IGNITION SYSTEM 8 1 EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 330: ...ELECTRIC STARTING SYSTEM 8 7 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 336: ...CHARGING SYSTEM 8 13 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 339: ...CHARGING SYSTEM 8 16 ...

Page 340: ...LIGHTING SYSTEM 8 17 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 344: ...SIGNALING SYSTEM 8 21 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 351: ...SIGNALING SYSTEM 8 28 ...

Page 352: ...COOLING SYSTEM 8 29 EAS27300 COOLING SYSTEM EAS27310 CIRCUIT DIAGRAM ...

Page 355: ...COOLING SYSTEM 8 32 ...

Page 356: ...FUEL INJECTION SYSTEM 8 33 EAS27330 FUEL INJECTION SYSTEM EAS27340 CIRCUIT DIAGRAM ...

Page 395: ...FUEL INJECTION SYSTEM 8 72 ...

Page 396: ...FUEL PUMP SYSTEM 8 73 EAS27550 FUEL PUMP SYSTEM EAS27560 CIRCUIT DIAGRAM ...

Page 399: ...FUEL PUMP SYSTEM 8 76 ...

Page 400: ...ELECTRICAL COMPONENTS 8 77 EAS27970 ELECTRICAL COMPONENTS ...

Page 402: ...ELECTRICAL COMPONENTS 8 79 1 5 4 3 2 6 7 8 9 10 12 13 11 14 15 16 17 18 ...

Page 404: ...ELECTRICAL COMPONENTS 8 81 EAS27980 CHECKING THE SWITCHES ...

Page 431: ......

Page 432: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...