CRANKSHAFT

5-58

EAS2DM1082

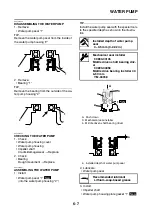

CHECKING THE OIL STRAINERS

1. Check:

• Oil strainers

Damage

→

Replace.

Contaminants

→

Clean with solvent.

EAS2DM1083

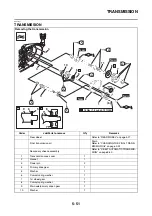

INSTALLING THE CRANKSHAFT

1. Lubricate:

• Oil seals

• Bearings

• Oil pump drive gear

2. Install:

• Oil seal “1”

(to the left crankcase)

3. Install:

• Bearing

(to the right crankcase)

4. Install:

• Crankshaft assembly “1”

TIP

• Install the crankshaft assembly with the crank-

shaft installer pot “2”, crankshaft installer bolt

“3”, adapter “4”, and fork seal driver attachment

“5”.

• The fork seal driver attachment should only

contact the inner race of the bearing.

NOTICE

ECA13970

To avoid scratching the crankshaft and to

ease the installation procedure, lubricate the

oil seal lips with lithium-soap-based grease

and each bearing with engine oil.

TIP

Hold the connecting rod at top dead center

(TDC) with one hand while turning the nut of the

crankshaft installer bolt with the other. Turn the

crankshaft installer bolt until the crankshaft as-

sembly bottoms against the bearing.

5. Install:

• Oil pump drive gear “1”

TIP

Install the oil pump drive gear with the crankshaft

installer pot “2”, crankshaft installer bolt “3”, and

adapter “4”.

Recommended lubricant

Oil seal

Lithium-soap-based grease

Bearing, oil pump drive gear

Engine oil

Oil seal installed depth

0–0.5 mm (0–0.020 in)

a. Oil seal installed depth

1

a

Crankshaft installer pot

90890-01274

Installing pot

YU-90058

Crankshaft installer bolt

90890-01275

Bolt

YU-90060

Adapter (M14)

90890-01478

Adapter #6

YM-90066

Fork seal driver attachment

90890-01186

Replacement 27 mm

YM-A9409-1

3

2

4

5

1

Summary of Contents for MBK XMAX 2014

Page 1: ...2014 SERVICE MANUAL YP125R YP125RA 2DM F8197 E0 ...

Page 6: ......

Page 8: ......

Page 64: ...TIGHTENING TORQUES 2 17 Muffler tightening sequence 1 2 3 ...

Page 72: ...LUBRICATION SYSTEM DIAGRAMS 2 25 EAS2DM1116 LUBRICATION SYSTEM DIAGRAMS 1 2 3 4 5 3 ...

Page 78: ...CABLE ROUTING 2 31 Steering head front view 1 2 3 4 5 6 8 8 A 7 7 ...

Page 80: ...CABLE ROUTING 2 33 Front brake left side view for YP125R 1 2 2 1 1 2 2 D E A B C ...

Page 82: ...CABLE ROUTING 2 35 Front brake left side view for YP125RA 2 1 1 2 1 2 2 A B D E C ...

Page 92: ...CABLE ROUTING 2 45 Frame right side view 3 2 4 1 2 3 A B 6 5 3 A B 3 3 2 3 3 A A B A B B 3 ...

Page 94: ...CABLE ROUTING 2 47 Engine right side view 6 6 6 6 C D C D D C 10 B 9 5 6 1 2 8 3 4 5 6 7 A ...

Page 98: ...CABLE ROUTING 2 51 Frame left side view C D C D 2 1 E 1 2 D C 6 1 4 5 3 2 1 7 3 2 1 A B ...

Page 100: ...CABLE ROUTING 2 53 Engine left side view 1 1 1 1 1 2 3 4 5 6 7 8 9 7 7 A B A B A B 1 ...

Page 106: ...CABLE ROUTING 2 59 Rear brake right side view 2 2 2 2 2 2 1 1 2 3 A B C 3 ...

Page 110: ...CABLE ROUTING 2 63 ...

Page 228: ...REAR SHOCK ABSORBER ASSEMBLIES AND SWINGARM 4 89 ...

Page 231: ......

Page 291: ...CRANKSHAFT 5 60 a 1 ...

Page 292: ...CRANKSHAFT 5 61 ...

Page 302: ...WATER PUMP 6 9 ...

Page 313: ......

Page 331: ...CHARGING SYSTEM 8 18 ...

Page 349: ...COOLING SYSTEM 8 36 ...

Page 391: ...FUEL PUMP SYSTEM 8 78 ...

Page 400: ...IMMOBILIZER SYSTEM 8 87 a Light on b Light off ...

Page 401: ...IMMOBILIZER SYSTEM 8 88 ...

Page 405: ...ABS ANTI LOCK BRAKE SYSTEM for YP125RA 8 92 ...

Page 439: ...ABS ANTI LOCK BRAKE SYSTEM for YP125RA 8 126 ...

Page 464: ...ELECTRICAL COMPONENTS 8 151 ...

Page 476: ......

Page 477: ......

Page 478: ......