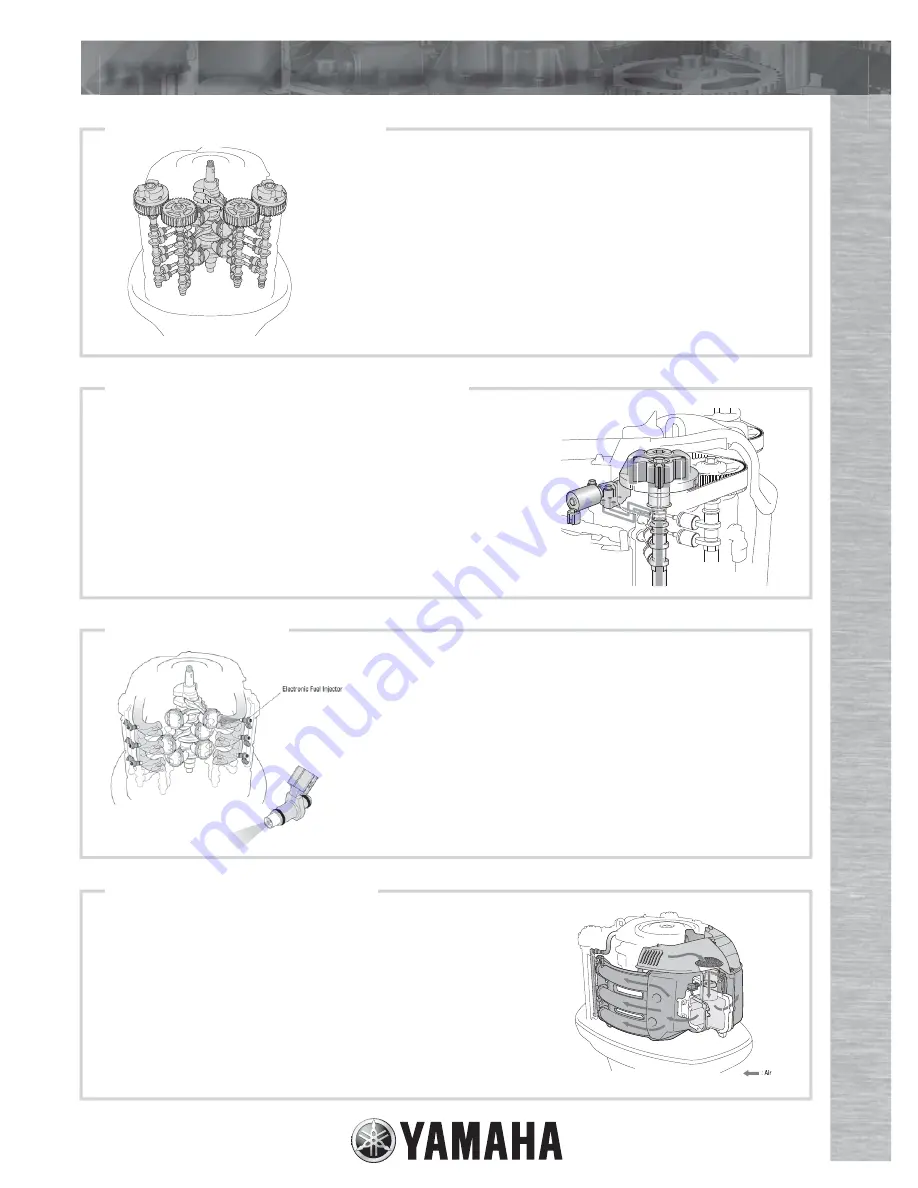

POWERFUL PERFORMANCE

Yamaha’s variable camshaft timing system advances and

retards the angle of the intake camshaft to dramatically

increase power and throttle response in the low- and

mid-rpm ranges. This gives the engine substantially greater

torque between 2000 ~ 3500 RPM to provide excellent

power to plane.

All air entering the engine block of the F250B is routed

through a single electronically-controlled throttle valve,

to ensure the precise amount of air necessary for optimum

power and fuel effi ciency. The air silencer box reduces

intake noise and air turbulence for smooth, quiet operation.

Individual intake and exhaust camshafts provide more

precise valve timing control and have less moving parts

than conventional push rod systems for increased reliability.

This superior design also allows for use of 4 valves per

cylinder which exchange intake and exhaust gases more

effi ciently for responsive power and increased fuel economy.

Reliable and Responsive

Hole Shot and Mid-Range Punch

Fuel Effi ciency

Six individual compact electronic fuel injectors deliver the

exact amount of fuel needed for optimum performance and

economy. Controlled by the Engine Control Module via input

from an array of on-engine sensors, their location just above

the intake valves enhances fuel atomization, resulting in

more effi cient combustion.

Precise Throttle Control

Reliable and Responsive

F250B

featuring

Command Link

®

Controls and Gauges

F250B

featuring

Command Link

®

Controls and Gauges