– 7 –

SPEC

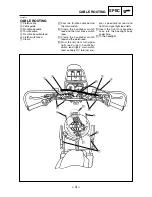

CABLE ROUTING

å

∫

ç

∂

´

ƒ

©

˙

ˆ

∆

˚

¬

µ

1

2

3

4

5

6

7

8

9

0

©

Pass the wireharness to the far-

thest left side.

˙

Clamp the wireharness, CDI

unit lead, magneto lead, throttle

cable, and starter (choke) cable

on the center of the engine

mount stay.

ˆ

Clamp the wireharness.

∆

Clamp the handlebar switch

lead and clutch cable.

˚

Pass the starter (choke) cable

and handlebar switch lead

through the outside of the cable

guide.

¬

Pass the throttle cable and

clutch cable (under side) into

the cable guide .

µ

Pass the starter (choke) cable

in front of the throttle cable and

clutch cable.